-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

January 7, 2021

How are Hargrove Engineers Radically Improving Industrial Plant Productivity?

Hargrove Engineers + Constructors is a unique organization in the sense that they tackle a wide range of engineering disciplines and problems. They work with a broad spectrum of customers that cover a myriad of industries.

Hargrove uses Ansys’ tools for advanced engineering problems that cannot be accurately captured with approximate or empirical methods. For example, the critical buckling limit of a beam is easily calculated, but what about the buckling limit of a beam that is already deformed or installed out of square? That is just a simple example where simulation tools are required.

“Our goal is to solve all of our clients’ technical and business issues associated with their industrial plants,” says Keith Hays, director at Hargrove Engineers + Constructors. “With clients in diverse industries ranging from aerospace to manufacturing to pharmaceuticals, Ansys simulation solutions make us more efficient in solving some of the more complicated and specialized problems that come across our desks.”

Hargrove engineers rely on Ansys flagship products, including Ansys Mechanical and Ansys Fluent, to solve challenging industrial plant engineering problems. And by leveraging Ansys Cloud’s high-performance computing (HPC) capabilities, they are running simulations faster than ever, significantly reducing the development time and cost for their clients.

“Whether it’s a complex vibration problem, a corroded tank that needs to be rerated or blast rating a structure, Ansys gives us the toolset to create computational models and digital twins of the affected systems, allowing us to evaluate different scenarios and quickly identify the best option for solving our client’s problems,” says Hays.

Ansys Fluent combined with Ansys Cloud allows Hargrove engineers to solve fluid-induced vibration problems on-the-fly.

Enhancing Plant Productivity with Ansys Mechanical

In support of chemical, petrochemical and refinery related projects, Hargrove relies on Mechanical Enterprise to solve problems involving piping, pressure vessels, rotating equipment and structures.

Hargrove regularly works with customers that are modifying or rerating equipment. Rerating pressure vessels instead of replacing them is a massive timesaver because companies typically require months of lead time to order and install a new vessel. “With Ansys Mechanical, we can perform fully elastic-plastic analyses and return the vessel to service in just a couple of weeks with full confidence,” says Benjamin Turner, mechanical engineer at Hargrove.

How else does Ansys Mechanical come into play? When a customer buys a pressure vessel, the vessels are rated for specific design conditions. For example, the vessel will rate at 400 pounds per square inch at 300 F. If the customer needs to use it at 500 pounds per square inch at a higher temperature, they need to rerate it, which cues Hargrove engineers to perform finite element analysis on a computational model of the vessel rather than performing tests in the field to see if rerating is possible.

Recently, Hargrove engineers were tasked to help a chemical processing plant rerate an in-service pressure vessel. This large vessel was a condenser that required a full vacuum rating during operation. During an inspection, a large area of corroded shell was found that pushed the allowable vacuum rating below code requirements. This presented a significant danger of localized buckling and failure of the shell as tremendous vacuum is created inside the vessel.

“The sheer immensity of this high-alloy structure — nearly 12 feet in diameter, 20 feet tall and containing 4000 heat exchanger tubes — would’ve been too difficult and expensive to analyze without simulation,” says Turner.

Using Mechanical Enterprise to perform a fully non-linear initially-perturbed buckling analysis, Hargrove engineers developed and positioned patch rings across the vessel’s surface that returned the condenser to its full vacuum rating without moving the vessel or performing complicated repairs. This ultimately saved the customer weeks of development time and hundreds of thousands of dollars in replacement fees.

Saving Development Time and Cost with Fluent

In addition to Ansys Mechanical, Hargrove also relies on Fluent to solve multiphase flows, combustion/reacting flows and fluid-structure interactions for its customers.

Recently, in support of a leading polymer manufacturer, Hargrove engineers inspected a tank expansion joint that was failing and had experienced multiple ruptures, with each rupture causing polymer to leak and spray out onto nearby equipment.

Using Fluent, engineers created a moving mesh analysis, enabling them to visualize the ball valve opening. As the liquid drained, Fluent helped them quantify the magnitude of transient pressure pulses. Viewing the behavior of this computational animation allowed the customer to understand that the transient pressure was three to four times the rating of the expansion joint, demonstrating the need for a new, higher-rated expansion joint. “By replacing the joint, our client avoided subsequent ruptures, which would’ve cost them hundreds of thousands of dollars in repairs and lost output,” says Turner.

Harnessing the Power of Ansys Cloud for Systems Simulations and Digital Twins

Ansys Cloud and Ansys Twin Builder enable Hargrove engineers to scale Ansys technologies at-will and to mitigate large capital investments in hardware and software. The ability to queue massive multicore supercomputers on-demand is extremely exciting for Hargrove engineers. Having scalable computational power at their fingertips equips them to generate more reduced order models (ROMs) of complex products.

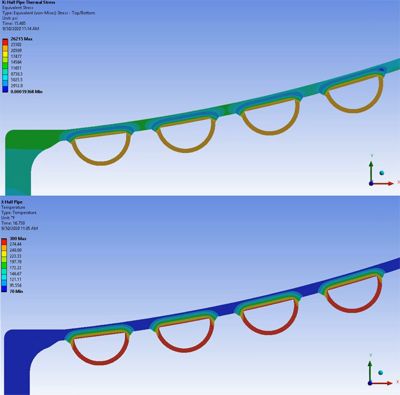

These ROMs are then used on premises and brought into Ansys Twin Builder to create systems simulations that allow interlinked phenomenon to be reduced in a computational process akin to curve fitting. For example, Hargrove engineers created a system of a half-pipe jacketed vessel to model how fluid properties affect the fatigue life of chemical reactors. As the metal of the vessels expands and contracts, stresses are created in response to thermal expansion differences. After enough of these thermal cycles, the vessel forms a crack in the jacket and leaks. The number of cycles depends on many different variables. Evaluating each one used to require multiple individual models. With Twin Builder and Ansys Cloud, Turner says they now have the computing power needed to understand emergent behaviors like the jacket problem. In the future Hargrove plans to connect the simulations to in-field assets through an industrial internet of things (IIoT) platform, creating a digital twin.

Ansys Mechanical helped create a response surface of thermal stress generated from fluid heating an agitated chemical reactor equipped with a half-pipe jacket.

“When I was a kid, I never thought power like this would be possible in my lifetime,” says Turner. “With Ansys Cloud, the ability to immediately scale up machines is unparalleled. It eliminates the need to install any software and delivers pure convenience. I can use my smartphone to check my simulation’s status.”

Get a deeper dive into Ansys Cloud. Or try it for yourself with a Free Trial.