-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

March 25, 2021

Create Your Minimum Viable Product Using Simulation

Most startups face a common problem: Investors and customers will not engage until there is a product for them to engage with, but the product development team cannot learn from the first iteration of a product until customers engage. That is why creating a minimum viable product (MVP) is now a standard part of the startup journey.

For software companies, cranking out some code is fast and relatively affordable. But if your company develops physical products, the cost of creating an MVP often puts you in a chicken-or-egg situation. You need funding and time to manufacture an MVP, and you can’t get funding until you have an MVP that can demonstrate your product. You can’t show customer acceptance until customers can interact with your product.

That is where creating a digital twin via numerical simulation comes into play. By creating a virtual version of your MVP, your team can test your product and then demonstrate it to customers and investors.

What is a Virtual MVP?

The common definition of a minimum viable product is one with just enough features to make it work. However, there is more to it than that. Entrepreneur and author Eric Ries, who popularized the concept, defines an MVP as “that version of a new product which allows a team to collect the maximum amount of validated learning about customers with the least effort.”

An MVP becomes virtual when you create a digital version using simulation software. Most companies create virtual prototypes of their products during the product development stage. These models are generally used to look at the robustness or performance of a product. What makes such a simulation a complete electronic copy, often called a digital twin, is when it behaves just like the product would in the real world.

If your product is a new mousetrap, you may be using simulation to calculate how much force is needed on the trigger to set off the trap. A digital MVP would allow you, your customers and your potential investors to set the trap, see how various possible mouse interactions play out, and even how to remove a mouse from the trap — all on the computer.

Remember, the goal of an MVP is to collect validated learning with the least effort. A virtual version of your product, built with simulation software, is a great way to get that information with considerably less effort.

How to Create a Digital MVP

The starting point when creating a virtual version of your initial product is to follow standard product development guidelines. Capture your specification, identify your features and plan your development. Because you are shooting for an MVP, you need to determine what is required to get to the point where you can test the entire product.

Next, use simulation to drive your design. Most successful physical product companies already do that. Virtual testing and interactions within each design step are critical to getting a working product as quickly as possible and are much faster than traditional build-and-bust cycles.

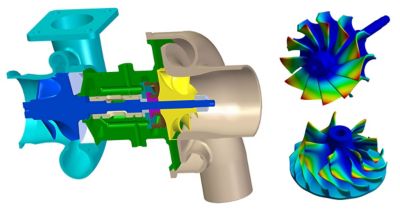

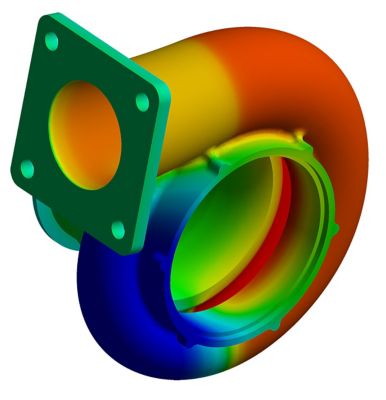

Choosing which simulation tools to use is probably the most crucial decision you will make. The tools you choose need to work together, model all the physics your product exhibits, respond in a reasonable time and allow your customers to see how your product performs. This requires a platform that is accurate and can handle the interaction between physics. If needed, it should also integrate with circuit simulation and model your controls and software.

Starting with a system-level model from day one is where things differ from a development plan being rushed to manufacturing. This digital twin can begin very simply, maybe even in a spreadsheet. However, as you refine the design, your simulations of each aspect should become more detailed. Leverage the ability of more detailed simulation tools to create reduced-order models (ROMs) that you can plug into your system-level model. ROMs enable you to reduce simulation run times and speed up development cycles.

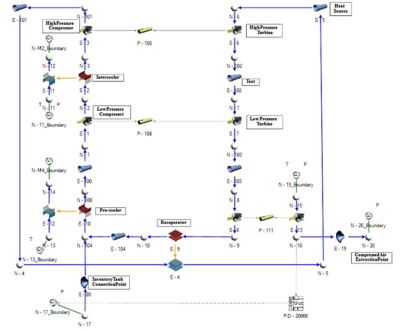

An example of a system-level simulation model.

If you have a system that includes controls or software, make sure you are using a simulation platform that can easily integrate your controls simulator and your software. “Hardware-in-the-loop” testing is a common testing step. With a digital MVP, you are just replacing the physical hardware with a digital, simulated version

Lastly, keep in mind that people outside of your organization will be using your virtual product. Plan for an interface that works for them. This may be as simple as a dashboard where they can enter parameters and see the response, or as sophisticated as a virtual reality interface with haptic devices.

Leverage Simulation to Get to Market, or Funding, Faster

Think of it this way: In the Software-as-a-Service (SaaS) world, they always create a virtual version of their product for customer validation. Why shouldn’t hardware companies do the same? The time and cost of spinning up manufacturing, even for prototypes or limited production, is a long and difficult part of getting a physical product to market. And if initial usage by customers reveals needed changes, the cost of retooling can be significant.

Almost every aspect of your business is going digital. Take the next step and create a virtual MVP. It could be the key difference that gets you over the hump and on your way to success.