-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

August 30, 2023

Building Efficient Power Solutions by Connecting Digital Threads

Sometime around 2014, Frédéric Bussières, then a simulation engineer at GE Power, was caught up in a company initiative to accelerate first-time-right solutions for the company’s most critical components using early visions of the emerging concept of a digital thread.

“I was writing in JavaScript to automate the creation of models — trying to really automate anything and everything,” he recalls. “But building methods at the same time as trying to automate them is very difficult. So, it was a little too much too early, and it earned me the nickname of ‘Digital Fred,’” he says with a laugh. “It stuck.”

INNIO’s headquarters in Jenbach, Austria

Today, Digital Fred is Senior Team Manager, Global Mechanical Simulation of the INNIO Group, headquartered in Jenbach, Austria. INNIO’s Jenbacher technologies deliver efficient, sustainable distributed heat and power for commercial, industrial, and municipal applications.

Jenbacher engines are known for their efficiency and robustness and run on a broad range of sustainable energy sources, from pipeline gas to hydrogen. These include other renewable gases such as biogas, biomethane, landfill gas, and sewage gas, as well as special gases such as syngas (a blend of CO and H2). To date, over 24,000 Jenbacher engines have been delivered in about 100 countries.

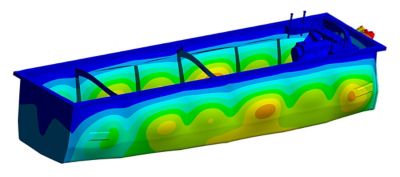

Simulation of an INNIO oil pan

“For INNIO, sustainability means an everlasting pursuit of innovation to develop energy solutions of higher efficiency and lower emissions,” Bussières says. “Decarbonization, with hydrogen or other fuels, also means overcoming new material challenges presented by these innovations. For instance, this means dealing with higher temperatures, more challenging combustion mechanisms, and potentially new failure modes. All that puts pressure on our engineering methods.”

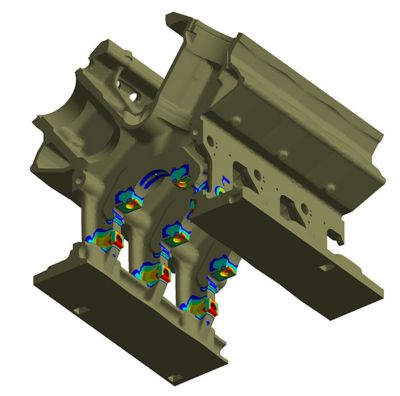

To relieve some of that pressure, INNIO uses Ansys Mechanical and Ansys Workbench to simulate static structural, steady-state thermal, transient thermal, structural optimization, harmonic analysis, and random vibration properties of their engine models. They have also used Ansys LS-DYNA explicit simulation to determine the response of materials to short periods of severe loading. Recently they adopted Ansys Granta materials tools to ensure they are using the best materials for each component. For simulation of fluids, they use Ansys CFX and Ansys Fluent for waterside boundary conditions.

Perhaps more importantly, Bussières and his team have used Ansys Workbench and the Ansys ACT and Ansys Parametric Design Language (APDL), along with other scripting tools, to create digital engineering workflows that automatically integrate these simulations in a digital thread. Instead of having to manually export data from one simulation into the next step in the simulation chain, scripting makes the workflow — data transport and movement from one type of simulation to the next — streamlined, automatic, and therefore faster and more efficient. It gives engineers more time to focus on the end goal, with seamless iterations and faster innovation rhythm.

Simulation of an INNIO crank case

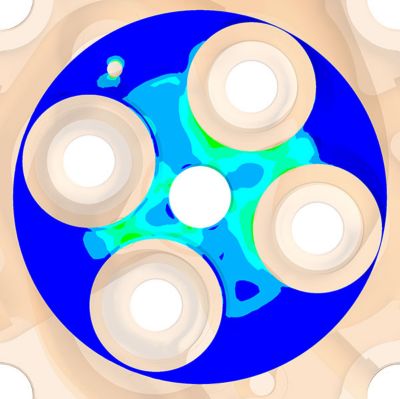

A simulation of the gradient of equivalent plastic strain (DPEEQ) in an INNIO component

Bussières manages a team of engineers that is responsible for all engine platforms, including platforms featuring multiple cylinder counts and numerous product configurations. Coordinating the work of such a team of engineers and projects is made easier and more efficient with digital engineering. INNIO has been innovative in optimizing the parameterization process, inventing better ways to display simulation results, selecting the right material for the application, and much more. Ansys simulation plays an important role in the team’s efforts.

Automating Optimization

Parameterization is what started Bussières in simulation. He soon found that the capability of automation and programmed sequences of simulations to investigate a wide range of parameters automatically and determine an optimal configuration for a component was essential to engineering success.

“The first kind of assignment I had using Ansys simulation solutions was purely parametric, so I had to develop very extensive APDL scripts for building geometry for FEA (finite element analysis) models from scratch — from zero to a report basically,” Bussières says. “And then on top of that, running designs of experiments (DOEs) and optimization simultaneously — a process of fully parameterizing a piece of work from cradle to grave. When I started using Ansys Workbench, I recognized that there was a roadmap to further improving this process. So, by parameterizing the geometry and environment, parameterizing just about anything and adding customization on top of it, I feel like I am steering the design somewhere, and gaining ownership of the design space.”

INNIO uses CADNexus to produce designs along with Ansys Mechanical FEA software in an Ansys Workbench environment. The Ansys Workbench platform enables them to integrate data across engineering simulations to create more accurate models more efficiently.

“Combining Workbench and CADNexus to bring parameterization to the FEA world has been a really foundational benefit of Ansys’ approach versus that of their other competitors,” he says.

The combination has paid off for INNIO.

“The original cycle time of a cylinder head analysis was too long,” Bussières says. “It would take us weeks to get to a point where we had documented and understood what an iteration looked like, from fluids to the structural results and lifing. And now we can perform all these multiphysics simulations in a couple days. So, within a week we’ve got several concepts, on which we can further iterate at a greater speed. That makes us a lot more efficient and successful, and gives us confidence in the robustness of our solutions. I think that’s thanks to our ability to explore the design space, and iterate quickly, and learn fast from what we put together.”

Digital engineering, specifically maintaining the chain between CAD and FEA, is key to INNIO’s efficiency.

“When we follow our internal engineering process, it guides us toward a coupled interaction between the designer and CAE,” Bussières says. “With Workbench, we have a very robust way of bringing new geometry in and empowering the analyst or the CAE engineer to own that design in a certain sense, to iterate on it, which is paramount to analysis-led design.”

Connecting the Digital Thread to the Business

Given the size of the CAE team at INNIO, the role of analysts is far more than one of displaying results with colorful pictures. INNIO’s “need for speed,” as Bussieres puts it, requires quality and efficiency to be encapsulated into methods.

“We needed to move away from colors and gut feeling assessment to metric driven solutions,” he says. So, starting in 2016, they used Ansys ACT to develop a digital toolbox containing 20 tools for translating the shades of the rainbow from FEA results into something that shows the results more factually and effectively.

Meshing of an INNIO crankshaft

To improve the communication of results within the team, Bussieres developed key- performance-indicator-based (KPI-based) assessments that have been very helpful in making INNIO’s FEA models more easily understood.

Some KPIs are cost-centric, some are value-creation centric, and some involve resource demand. “We’ve reduced consistently and considerably the cost of quality liability we had in the past. And that’s, in my opinion, thanks to the investment we put into method development, into simulation knowledge. It’s been a long journey, but the vision is paying off. All these customized tools are meant to translate FEA results into something more meaningful,” Bussières says. “They divert your attention away from the ‘rainbow’ colors of a result to a more metrics-based and KPI-based assessment.”

The Benefits of Simulation

“Simulation makes us more efficient at protecting our customers’ interests, by tackling innovation and making sure they’re competitive and profitable,” Bussières says. “By protecting the longevity and life cycle of their assets, and by providing retrofittable innovation along the way, we are preserving their present and future return on investment. We do that by having faith in the results of our simulation and development efforts. The faster we can do it, the faster they can get it. So, reducing the cycle time of our engineering development gets our products to the field quicker, and it helps us differentiate ourselves from the competition.”

Such a commitment toward engineering methods is part of an initiative called “Future Engineering.” Andreas Kunz, INNIO’s CTO, reflects on the matter: “Increasingly demanding performance from our products requires equal commitment to innovation and engineering excellence. Future Engineering is our way to translate our vision for a sustainable future with development efforts, using cutting-edge methods and simulation tools.”

“It’s been exciting,” Bussières concludes. “We can proudly say that our work enables reducing the cost of quality while also creating future value. Savings in the future and value in the future — that’s double the benefit.”