-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

September 26, 2022

Ansys Takes to the Skies to Help Power Zero-Carbon Jets of the Future

For most travelers, weighing the cost of flying versus driving is often a matter of dollars and common sense. The calculus that goes into this decision depends on the number of passengers, how far you are traveling, and how quickly you need to get where you’re going. For the eco-conscious traveler, it has become a matter of social responsibility as well. It all boils down to the lowest-carbon option: driving or flying. And this is where we enter the no-fly zone.

Hands down, the per-passenger carbon footprint of an airplane is larger than that of a vehicle, particularly if you’re traveling domestically.1 As electric vehicles start to pop up with greater frequency, the gap will undoubtedly widen, putting the focus squarely on-air travel reform to drastically reduce carbon emissions.

To this end, Ansys is supporting research led by the University of Central Florida (UCF) and funded by a $10 million NASA University Leadership Initiative five-year grant to accelerate aviation sustainability. During this project, eight different organizations will come together, including Ansys, to develop new ways to use non-carbon-based fuels for aviation. This work is in support of a worldwide aviation goal to reach near-zero-emissions by 2050. Because aviation is a global industry tied to a global supply chain, any research results will undoubtedly have significantly positive global implications.

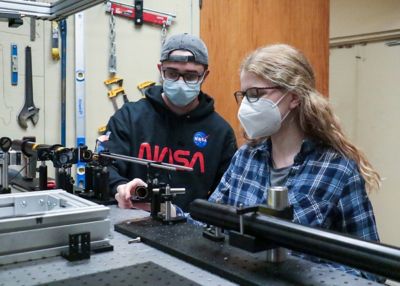

Graduate student Jonathan McGaunn and undergraduate student Marley Albright working on coupling advanced laser spectroscopic instruments with UCF CATER’s HiPER STAR shock tube facility to gather combustion experimental data at engine-relevant conditions.

UCF Researchers Spread Their Wings in New Directions With Ansys

One of the most difficult sectors to decarbonize is aviation, which must balance weight, volume, and subsystem requirements with non-carbon-based fuels. Over the last two decades, zero-emission aviation has focused on using drop-in biofuels to replace fossil-based jet fuels. They’re an attractive near-term option to reduce carbon emissions because they can be incorporated into the global fleet with no aircraft hardware or major infrastructure changes required. While significant advances have been made in the chemistry and production of such fuels, scaling up manufacturing capabilities to provide cost-competitive, drop-in jet fuels for the global fleet to completely eliminate emissions has been a challenge.

Any new technology for aviation must address several concerns concurrently, including the technical requirements for commercial aviation, the overwhelming concern for safety, the extent and cost for upgrading the global fleet of airplanes and airports, and the global supply chain. Even though the first concern is UCF’s primary focus for the upcoming project, no new technology will be successfully transitioned to market without sufficient attention to the other three — essentially there needs to be holistic optimization of all four. For this reason, with significant attention to technology transition, the work will address all four barriers to adoption.

Dr. Jay Kapat, the lead investigator of the newly funded research project and an engineering professor at UCF, is working on an alternative, scalable pathway to zero-emission aviation using electricity-derived (or green) liquid ammonia (NH3) as a hydrogen carrier to meet these objectives. His vision is to leverage NH3 for multiple purposes to nearly eliminate emissions and significantly improve engine efficiency. In this scenario, the use of supercritical carbon dioxide (sCO2) in a closed Brayton cycle — a thermodynamic cycle for exhaust heat recovery (EHR) — further reduces fuel consumption.

“We want to create a scalable solution for cleaner aviation and with Ansys’ cooperation we will get there faster,” says Kapat in a recent press release. “We would not be able to authenticate the use of liquid ammonia as a reliable and alternate fuel without the sophistication and capability of Ansys’ fluids simulation tools.”

Cracking the Case for Liquid Ammonia

So what, specifically, does Kapat’s vision to make commercial air travel more sustainable entail? In place of jet fuel, liquid ammonia will be used for depressing air that would be stored at airports as a liquid, and that liquid ammonia would then be fueled into the plane engine or tank. Flying at cruising altitude, because of the temperature at that altitude, the ammonia would remain as a liquid, and unlike hydrogen, would not require extra effort to maintain its liquid form. The liquid ammonia would be vaporized, then cracked into hydrogen and nitrogen, which would be visible in the engine’s compression chamber.

Internal hydrogen combustion simulation animation highlighting the role Ansys tools are predicted to play in the aviation sustainability project at UCF.

Any ammonia either left over from the cracking process or intentionally left to control the combustion process that is burned to produce heat around the turbine and through the exhaust end of the turbine engine would be captured by a heat exchanger. The encapsulated heat would then be converted to electricity for onboard usage. Alternatively, the extra ammonia could also be used for chemical reduction of the NOx or atmospheric pollutants — reducing them down to almost nothing. The coldness of the ammonia could also be used to condense the water, reducing its concentration. Because none of the components of this system are in use today, simulation will play an important role in all aspects of the research team’s proposed concepts.

Researchers will simulate these complex chemical reaction systems, including the vaporization of liquid ammonia inside heat exchange tubes, heat transfer, and the combustion of ammonia and hydrogen in the air, enabled by Ansys’ chemical kinetics and computational fluid dynamics (CFD) simulation tools, Ansys Chemkin-Pro and Ansys Fluent. Using ammonia as a main hydrogen carrier, they hope to induce chemical catalysis to leverage ammonia’s hydrogen components while only releasing safe emissions into the air.

At this point, you may be wondering, why not use hydrogen? In addition to the sustainability of ammonia, it is naturally liquid at high altitudes, easier to handle than hydrogen, and does not require additional storage. In contrast, hydrogen requires special handling at high altitudes, thermal management, and ample on-board cryogenic storage. Of course, battery-powered electric is an option, but primarily for smaller planes as opposed to larger, commercial-sized planes like 737s. The other aspect of ammonia that makes it very desirable is that it is part of a thriving global supply chain, making it a plentiful, economically resourceful alternative.

Flying Through Turbulence With Simulation

According to Kapat, there are a huge number of publications on this topic, and an infrastructure bill allocating billions2 for hydrogen and carbon capture renewal. All of this is very good news, but he was careful to emphasize that this is a very difficult, arduous path for his team, working through a cycle of analysis, simulation and testing to address challenges every step of the way. All components defining their solution are very important, requiring the proper simulation tools to arrive at realistic results needed to validate their efforts and ultimately realize success.

Today, simulation adoption in critical research like Dr. Kapat’s is fueling big ideas in sustainability, thanks to Ansys research products and resources specifically for researchers.

References

- Which form of transport has the smallest carbon footprint?, Our World in Data, October 13, 2020.

- Why the carbon capture subsidies in the climate bill are good news for emissions, MIT Technology Review, August 25, 2022.