-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

September 22, 2022

How Ansys and Amazon Web Services Use Digital Twins to Drive Greater Industrial Autonomy

Digital twins can deliver a tremendous amount of value by improving engineering designs and delivering predictive modeling to support industrial operations. However, creating and deploying digital twins at scale requires coordination across several organizational silos and boundaries. For instance, much of the engineering know-how about assets is available within the product or engineering departments, typically codified in simulation models. By combining forces, Ansys and Amazon Web Services (AWS) are helping organizations bridge these silos to deliver scalable digital twin solutions.

“The world is moving more towards autonomous operations, and in particular for industrial autonomy use cases, we see digital twins as an enabling technology,” says Adam Rasheed, Head of Autonomous Computing at Amazon Web Services (AWS). “You need to be able to understand how a system will behave under different scenarios to support autonomous decision making. Introducing a predictive modeling digital twin allows you to make predictions about the future under different potential scenarios.”

Ansys and AWS are collaborating to help drive simulation-based digital twin solutions supporting industrial autonomy for our customers. The idea goes beyond pure 3D contextual visualization, which is a starting point that enables you to visualize all the data associated with your in-service physical assets in a particular environment. Within this context, we’ll explain what a digital twin is, and how Ansys Twin Builder, AWS IoT TwinMaker, and advanced probabilistic methods can enable industrial autonomy for customers.

Leveling Up to Digital Twins

The generally understood definition of a digital twin is that it is a virtual representation of real-world entities and processes, synchronized at a specified frequency and fidelity. Often customers gravitate toward the idea of creating a digital twin for their unique use case prior to exploring the context of the challenge they are trying to solve. In a related blog, AWS proposed four distinct levels (L1-L4) of digital twins to consider.

Digital twin levels framework adapted from: Verdantix, Five Digital Twin Strategies For Industrial Facilities, 2019.

This is consistent with the customer journey that we have seen at Ansys — with levels 1 and 2 representing building blocks in terms of engineering modeling and data connectivity, and levels 3 and 4 representing more of the advanced predictive modeling analytics and insights that both Ansys and AWS can provide.

For the purpose of this blog, we will be focusing on levels 3 and 4 as they are defined here:

- L3 focuses on modeling the behavior of the physical system, where the behavior is same as in the past (e.g., virtual sensors, anomaly detection or short-time horizons looking forward). The predictive models can be machine learning-based, first principles-based (e.g., physics simulations), or a hybrid. In this context, we’re referring to physics and ML hybrid digital twins, such as those that can be generated by Ansys Twin Builder.

- L4 focuses on modeling behavior in which the physical system’s inherent behavior changes over time. Changes in behavior can occur as physical systems degrade or receive maintenance and upgrades, and they are relevant when making accurate predictions over long timescales. This typically requires applying probabilistic update and uncertainty quantification methods on top of machine learning-based, first principles-based, or hybrid models.

For digital twins, the distinction between L3 and L4 is seen in how the operational data from the real-world system is used. For L3, the operational data is used as an input to a pre-trained L3 model that provides a response output. The implicit assumption is that the prediction is well represented by past behavior (e.g., historical data used to train the model). For L4, the operational data is used to update the model itself using probabilistic (Bayesian) calibration techniques. The updated model is then used to make the forward prediction. In this way, the L4 model is always learning and reflects the latest behavior of the physical system.

The Ansys Twin Builder/AWS IoT TwinMaker Value Proposition

Ansys Twin Builder is an open solution that enables engineers to create physics-based digital twins with hybrid analytics. Each of these digital twins takes shape in an integrated, multidomain simulation that mirrors the life and real-world experience of that asset. Sensors mounted on an entity gather and relay data to a simulation model (the digital twin) to mirror the real-world experience of that product. Simulation-based digital twins enable tracking of the past behavior of an asset, provide deeper insights into the present, and can help predict future behavior of an asset — facilitating discovery that leads to system design optimization, predictive maintenance, and industrial asset management for customers. Ansys’ simulation software — specifically, Twin Builder — provides the simulation technology needed to build predictive (L3) and living (L4) digital twins.

AWS IoT TwinMaker is an AWS service in the Industrial Internet of Things (IoT) space that makes it faster and easier for developers to create and use digital twins to optimize industrial operations, increase production output, and improve equipment performance. The service today focuses on 3D contextual visualization (L2) use cases, which involves ingesting IoT data from the physical system and overlaying that data on a 3D virtual representation of that system so that a user can have full contextual awareness of the state of physical system. The service also focuses on the three main customer pain points of ingesting and querying disparate data across silos, making it easy to maintain the asset data model over its lifetime and creating effective visualizations (which could be a 2D dashboard or 3D immersive experience). By connecting AWS IoT TwinMaker with the simulation digital twins from Ansys Twin Builder, customers are able to build and deploy holistic L3 and L4 digital twin solutions.

"AWS' focus on providing scalable services for digital twins via AWS IoT TwinMaker is great news for customers," says Sameer Kher, senior director of Digital Twins at Ansys. "As customers build up and scale out sophisticated digital twins, the ability to leverage Ansys' best-in-class simulation software via Ansys Twin Builder and deploy using the AWS IoT TwinMaker service is going to be extremely critical."

Unlocking Simulation Investments to Enhance Operations

AWS IoT TwinMaker provides the ability to connect to data from a variety of endpoints, including sensor data from both the physical asset and simulation models. This is where Ansys Twin Builder fits in. In many practical use cases, the physical asset might not have the right sensors, or sometimes it is even physically impossible to use a sensor.

For example, shell and tube heat exchangers (shown below) are typically used in oil refineries and in the chemical processing industry for heating and cooling applications. While quite robust, the primary failure modes tend to be caused by thermo-mechanical fatigue. While sensing temperature at every location on the heat exchanger could help identify hot-spots and prevent failure, using physical sensors to do this is not feasible due to cost. An L3 digital twin of the heat exchanger, as demonstrated in this example, offers a solution. Using virtual sensors allows for a fine-grained representation of the temperature field. This representation can then be used to identify hot spots during operation. Suitable actions can then be taken to ensure that no failures occur.

Workflow of digital twin creation and deployment of heat exchanger equipment.

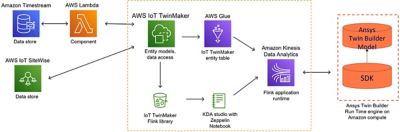

As shown in the architecture diagram below, adding Ansys Twin Builder into the mix also makes it easy to reuse existing simulation models created during the engineering design process and apply them within an operations context. The goal is to maximize the investment in simulations created during engineering design by making them available to operations. Using reduced-order models (ROMs) and system simulations, for example, engineers can build an accurate representation of a physical asset, then convert that into a runtime or software/instructions executed while a program is running for container-based deployment. The deployment easily fits into AWS IoT TwinMaker through APIs, which allows the customer to leverage simulations from their design engineering environment into the operations environment — including to a dashboard of the front end visible in AWS IoT TwinMaker, with Ansys simulation running as the predictive modeling engine behind the scenes.

Export a Twin Builder twin model that easily plugs into AWS IoT TwinMaker.

This is just one facet of the AWS/Ansys collaboration around digital twins. In our next blog, we’ll explore how Ansys Twin Builder and AWS IoT TwinMaker are leveraging the aws-do-pm open-source framework to enable customers to deploy predictive simulation models at scale. The framework provides built-in techniques to calibrate the model parameters using Bayesian estimation methods, calculate the error between predicted values and real-world data observations, and update the model parameters accordingly for an L4 digital twin.

Interested in unlocking the potential of Ansys Twin Builder to streamline operations? Sign up for a free trial of the simulation software.