-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

Ansys 軟體推動穩健的數位工程方法,協助驗證 ADI 車用電子產品的功能安全性。

車用技術正迅速演進,也出現了軟體定義車輛 (SDV),車輛中的關鍵功能已由軟體所主導與管理。根據《Forbes》報導,因應消費者對更智慧化、更具連網能力與更高效率車輛的需求,軟體定義車輛 (SDV)市場預計今年將達到 760 萬輛,較 2024 年的 620 萬輛顯著成長。

將硬體與軟體融合為標準化架構,讓車廠 (OEM) 在各項車輛專案中擁有更高的彈性與整合能力。在這樣的架構下,軟體成為核心推動力,能透過無線更新快速將新功能與功能升級推送至各系統 (以及系統之系統)。

更具挑戰的是,所有系統都必須符合 ISO 26262 標準,這是一項以安全為核心的產業規範,專注於複雜車用電子系統的功能安全 (FuSa) 要求。確立符合性是業界不可或缺的一環,因為它能確保車輛在長期運作下依然維持穩定可靠的性能表現,不容有失。

在這波技術浪潮的背景下,Analog Devices Inc. (ADI) 這家全球領先、致力於連接實體與數位世界的半導體企業,必須在其車用解決方案中因應這些嚴格標準,並防範日益複雜的網路安全威脅,這些解決方案正驅動著我們現今所駕駛的眾多車輛。ADI 的類比、軟體與數位解決方案,讓智慧邊緣能即時洞察關鍵資訊,協助重新定義車用生態系中價值的創造與傳遞方式。

這家在汽車產業生態系中扮演關鍵角色的公司,透過 Ansys medini analyze 軟體,從事半導體功能安全相關應用,同時進行以系統為導向的資安分析評估,全力支持其穩健的數位工程策略。

「隨著車輛日益朝向互聯化與自動化發展,對於穩健的功能安全與資安機制的需求變得更加關鍵。」ADI 功能安全總監 Kyle Fabris 表示。「由於難以有效率地對系統之系統(Systems of Systems)進行模型,此情況往往導致多個領域出現過度設計的問題。ADI 將重心放在智慧邊緣,開發能夠掌握連網系統複雜性的解決方案,藉此避免過度設計的傾向,同時確保安全性並強化自動駕駛技術。」

關鍵在於更聰明地工作,而不是更辛苦地埋頭苦幹

ADI 的完整解決方案提供關鍵基礎技術,支援各類應用,旨在確保系統的安全性並提升其整體運作效率。這些應用涵蓋先進駕駛輔助系統,以及電動化與自動駕駛車輛系統。

ADI 以簡單的積體電路為基礎,進一步打造出複雜的系統級封裝與完整的端到端解決方案。這過程需要將硬體、軟體與多顆晶片設計進行高度整合。

「我們目前在汽車產業中的位置 — 以及半導體未來的發展方向 — 都指向系統日益複雜,」Fabris 表示。「想要在一塊小足以安裝於車內各種安裝空間的電路板上解決所有問題,是不可行的。在自動駕駛車輛與電池管理系統領域中,ADI 的全面解決方案對於實現系統小型化、提升整體緊湊性與成本效益具有關鍵作用。半導體就是大勢所趨。」

確實,如今我們所享受的眾多車用技術,其基礎正是尺寸僅為數奈米的半導體幾何結構。在晶片製造過程中,ADI 面臨的重要挑戰是確保這些關鍵安全元件具備高度可靠性,符合國際標準,並能防範潛在的網路威脅以保護整體供應鏈安全。在實施這些解決方案的過程中,ADI 同時必須考量印刷電路板 (PCB) 的存取安全性、偵測離散元件中的故障,並針對其系統解決方案提供操作指引與使用假設。

「我們必須以更聰明且務實的方式來推動上百種安全機制的快速且高效率運用,因為這最終將使車輛本身變得更具效能、更安全也更具防護能力。」Fabris 表示。「關鍵在於將心力投入在真正該努力的地方,而不是為了努力而努力。Ansys 軟體在協助我們達成提升效率的目標上,扮演著不可或缺的關鍵角色。」

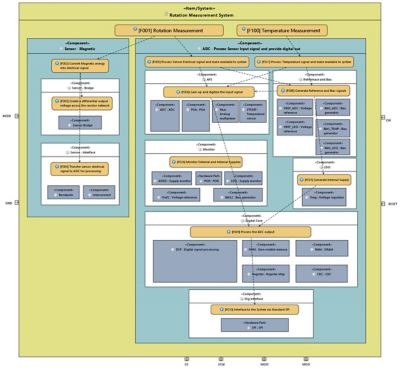

Analog Devices Inc. (ADI) 用於定義安全需求的典型圖示

推動功能安全的共識建立

為了跟上汽車產業中客戶需求的快速變化,供應商必須持續投入創新,形成不斷循環的研發節奏。要在這場競爭中取得成功,關鍵在於能在正確的時間提供客戶正確的資料,因為一旦發現潛在弱點,便需即時識別並於必要時重新調整架構予以解決。為達成這項目標,ADI 會在開發初期即與其功能安全與資安團隊密切合作。

「我們正透過 medini analyze 軟體建立所需的基礎架構,讓各團隊能夠運用一系列參考資料庫與元件目錄,快速建構設計概念。」Fabris 表示。「medini analyze 軟體同時也是我們實現基於模型的系統工程 (MBSE) 相關目標的核心基礎。它讓我們能將專家判斷整合進資料庫中,並以現有的實際資料為基礎,推動新設計的開發。」

專案總覽畫面顯示 ADI 建立的重複使用資料庫所構成的強化結構

根據 ADI 功能安全工程師 Richard O’Brien 回憶,他大約在八年前首次使用 medini analyze 軟體,當時採用的是以模型為本的設計方法,先建立與擴展設計概念,接著迅速進行深入分析。

「我們目前仍在持續推進數位工程策略的發展,同時開發功能並強化與 medini 軟體的整合。」他說。「它的功能非常靈活,讓我們能夠重複利用過去的專案、資料庫與元件目錄。這種高度彈性正是 ADI 在智慧邊緣領域保持領先的關鍵,讓我們能夠依照自身的開發目標,靈活整合其他第三方軟體工具。」

靈活運用數位工程策略

將 Ansys 軟體納入 ADI 整體數位工程策略後,也促成了意想不到且具價值的發現。整體而言,團隊從該工具中獲得的新彈性與客製化能力,已成為一大顯著效益。

「若從架構開發的角度來看這項整合,我們正在串聯更多層面的資訊。」Fabris 表示。「我們是在一個以模型為基礎的環境中完成所有作業,而不需要產出大量文件。我們透過快速執行以風險為導向的分析,實際獲得了顯著效益。而且我們能夠在概念階段就完成設計推演,並提供清楚可追溯的連結作為我們深思熟慮整體架構的有力證據。」

在 medini analyze 軟體的協助下,我們能夠建立資料庫,將過去的資料應用於新晶片或系統的製造流程中。具體來說,它讓團隊能將專家的專業判斷整合至新建的資料庫中,並依據真實世界資料推動新設計的開發。團隊無需從零開始,而是可以取用根據過往設計為特定應用事先定義並填入的歷史資料。

ADI 也透過使用開放原始碼軟體自動產出文件,在作業效率上獲得顯著提升。目前,團隊正與 Ansys 合作,將這項功能整合進現有工作流程中,打造一套一鍵式報告產生工具。這將大幅減少撰寫對客戶文件與內部報告時,為了溝通細節而所需的時間與人力投入。

一個 sysML 模型,其中透過 ADI 的重複使用資料庫建立模型式架構,使產品開發初期即能進行功能分析

當然,建立穩固的提高效率框架,是 ADI 數位工程策略中的一大重要核心。然而,medini analyze 軟體所帶來的高度信任感 — 這種信任已在整個產業中深具共鳴 — 也是ADI 所仰賴的事物。

「如果我們在功能安全上有所疏漏,或是設計不當、資料不正確,那影響的不只是單一環節。」Fabris 表示。「這也是我們在每個環節都投注極大心力與謹慎態度的原因之一。medini 軟體在分析過程中提供我們所需的測試與驗證、溝通與文件化支援,協助我們順利打造安全且可靠的產品,交付給客戶。」

深入瞭解

我們已深入探討了功能安全分析的各個層面。請務必查看 Ansys medini analyze 軟體在資安威脅分析與風險評估上的應用,以及它在確保車用應用安全與防護方面所扮演的重要角色。