-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

July 28, 2021

Accelerating Toward Net-Zero with Hydrogen and Simulation

Hydrogen is poised to reduce greenhouse gas emissions and help major economic sectors achieve their net-zero carbon objectives by 2050. That’s the date many countries agreed to during a climate change summit earlier this year, and that the European Union, the United Kingdom and other countries have already made legally binding. To meet that goal will require an overhaul of energy use for many industries and the advancement of a number of emerging technologies, according to the International Energy Agency.

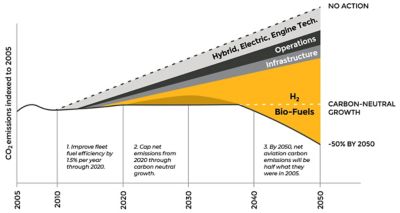

Figure1: Aviation sector’s commitment to net-zero (Source: IATA)

Synergy Across Industries Point to Hydrogen Adoption

Hydrogen is a significant part of the solution for carbon neutrality. There are synergies among major industries like aerospace, energy and automotive to establish a sustainable infrastructure network for hydrogen. It provides many pathways toward sustainability – from energy storage to cleaner energy production and propulsion – while complementing other solutions, such as batteries.

If we look at any of the industrial sectors in detail, we can see the potential impact of hydrogen to reduce greenhouse gas emissions. Let’s look at the aviation industry as an example. One proposed roadmap for net-zero carbon proposed for the aviation industry (see figure 1) shows that only a sustainable fuel, such as hydrogen, provides a realistic path to net zero by 2050. It's important to note that electrification will continue to help reduce emissions, especially with short-haul flights, but more than 90% of emissions in the aviation sector are produced by mid- to long-range flights, according to the Air Transport Action Group.

Similar observations can be made for other sectors where hydrogen-based solutions must play a critical role alongside other important technologies – such as energy efficiency, batteries and carbon capture – to achieve the net-zero goal.

“The decrease of the carbon content of power and the electrification of many economic activities (e.g. transportation or industry), benefiting from the strong decrease of renewable power costs, are key components of the roadmap for reaching the 1.5 C target by 2050,” says Claude Heller, former Director of Group R&D Programs for Air Liquide who is now a Senior Advisor for the Hydrogen Economy. “In the so-called hard-to-abate sectors (e.g. steelmaking or aviation) indirect electrification is possible via hydrogen produced by water electrolysis with low carbon power (e.g. renewables or nuclear).”

Three Key Challenges in Hydrogen Democratization Across Industries

Three major challenges with hydrogen democratization are cost, infrastructure and scale.

1. Cost

The cost of green hydrogen production (hydrogen produced using renewable energy) is around $5 USD per kilogram, which has made it less competitive compared to carbon-heavy fuels such as natural gas or kerosene. The high cost is linked to the infrastructure investment and demand, which is now getting a boost because of regulations and proactive actions being taken by governments around the world.

Investment in green hydrogen now exceeds $1 billion USD per year. The biggest investment, globally, has come from the European Union, which accounts for more than half of hydrogen-based project investments in the early part of this decade. The U.S. Department of Energy (DOE) just launched the Energy Earthshots Initiative in June for an accelerated energy transition. The first Energy Earthshot, called Hydrogen Shot, targets lowering the cost of green hydrogen to $1/kg by the end of the decade.

2. Infrastructure

With a significant investment in a hydrogen ecosystem, technical challenges related to hydrogen are back in focus. However, significant design challenges at each stage still exist – from its production to storage and transportation, to its end use. One of the major challenges at all stages is the energy efficiency of the devices involved. Fuel cell efficiency currently ranges between 40% and 60%, while the average electrolyzer efficiency is 60%. Significant improvements in efficiency are possible, but time consuming in a traditional build-test-improve design environment.

For example, hydrogen shows great promise in decarbonizing the aviation and power generation sectors with its end-use in gas turbines because of its high energy density and ability to burn lean. However, burning hydrogen in engines poses several technical challenges, including flashback, acoustic instabilities, autoignition and flame holding inside the burner.

Because of its low molecular weight and density, storage of hydrogen in a compact space is also a big challenge. It needs to be heavily compressed or stored in cryogenic/liquid form. The storage tank design, whether its flying in the sky on a plane or riding in the back of fuel cell vehicle on the ground, requires special consideration for embrittlement, leakage and associated safety risk.

3. Scale

Finally, there are end-use challenges related to scaling hydrogen. The current system size and weight of fuel cells are large, especially for aerospace and automotive applications. Their durability and reliability need to be improved for most transportation applications. Thermal, water and air management are also challenges when attempting to keep the size of the heat exchanger and overall system small.

“Current hydrogen technologies (e.g. electrolysis or fuel cells) are mature enough to engage the hydrogen economy at scale for decreasing the costs,” says Heller. “In parallel, there is still a need to improve processes in order to decrease the costs beyond the size effect. For that purpose, a better understanding and the modeling of electrochemical reactions at molecular scale and processes at system levels (e.g. cells or stacks) is essential.”

Simulation Technology Enables Hydrogen Adoption

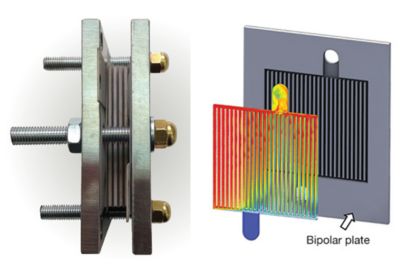

Ansys technology enables you to overcome the challenges associated with hydrogen by improving performance at every phase of its ecosystem and accelerating new technology development to address the cost and scale conundrum. For example, ENHIGMA a national project that involves different companies, as well as technological and research centers, used Ansys technology to manufacture low-cost, energy-efficient and durable proton exchange membrane (PEM) based electrolyzers and fuel cells. As shown in figure 2, Centro Nacional del Hidrógeno (CNH2) researchers optimized the PEM cell stacks using flow simulations in Ansys Fluent.

Figure 2: A PEM water electrolysis stack for hydrogen production (on left) with optimized cell design through Ansys simulation (on right)

Ansys simulation technology is used for individual cell design, cost-effective and lightweight material selection, cell-stack optimization for energy efficiency and thermal management of overall fuel cell and electrolysis system.

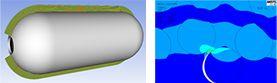

Cryogenic storage and transport are at the core of the hydrogen ecosystem. Ansys composites solutions can be used to design cryogenic vessels while closely mimicking its manufacturing process. The composite failure tool in Ansys Mechanical enables designers to evaluate potential failure modes and failure locations in-depth using advanced composite failure criteria such as Tsai-Wu, Puck and LaRC. It can be further be used to understand the effect of embrittlement and crack initiation and propagation, as shown in figure 3.

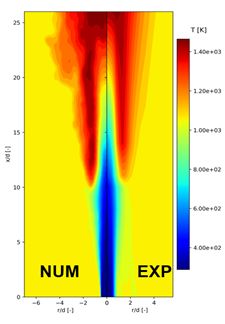

Hydrogen-powered gas turbine engines provide the most promising path for decarbonization efforts in the energy and aviation sector. The most complex technical challenges of hydrogen combustion – such as flashback, acoustic instabilities and autoignition – can be characterized and addressed with high-fidelity simulations. Figure 4 shows validation of CFD simulation methodology in Fluent for hydrogen combustion against experimental data.

Figure 3: A cryogenic liquid/compressed hydrogen tank design using Ansys Composite PrepPost (ACP) on the left and embrittle/crack analysis in Ansys Mechanical on the right

Finally, advanced digitalization technologies, such as digital twins and reduced order models (ROMs), can be used to optimize the operations of hydrogen-based systems. ROMs are simplifications of high-fidelity, complex models. They capture the behavior of source models so that engineers can quickly study a system’s dominant effects using minimal computational resources.

Figure 4: Ansys Fluent computational fluid dynamics (CFD) predictions for hydrogen combustion and its validation against experimental data

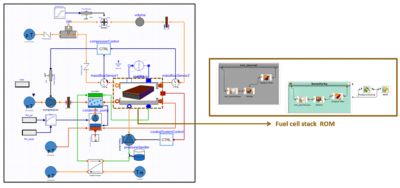

Figure 5 shows a digital twin of a fuel cell system created in Ansys Twin Builder. A typical hydrogen production system or hydrogen-based fuel cell plant contains many components. Most of these can be represented by a simplified model, but most critical parts – such as a fuel cell or PEM-cell stacks – can be represented by a ROM derived from Ansys 3D physics solvers. ROM creation for this digital twin is enabled by Ansys optiSLang, which automates the simulation toolchain and connects to algorithms for robust design optimization (RDO). With connection to live sensor data, this digital twin can monitor and optimize operations while enabling predictive maintenance.

Figure 5: Digital twin of a fuel cell system

By empowering engineers to explore more hydrogen design options faster and more affordably, simulation will help meet the top challenges related to increased hydrogen adoption. Being able to design and test hydrogen-related technologies in a virtual environment speeds time-to-market, which is critical as governments and industries rush to meet the 2050 net-zero carbon goals.

For more information on simulation solutions for hydrogen economy, please check out this on-demand webinar: Using Simulation to Help in Green Fuel Revolution: Hydrogen Life Cycle and the Role of Simulation.