-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS BLOG

May 11, 2022

Discover the Benefits of Simulation at the 20th International Icing Course

In all areas of engineering — aerospace in particular — simulation methods are reducing development time, manpower, and time to market while increasing safety and sustainability. Simulation is not meant to replace testing, but to be used as a companion to reduce and/or optimize it. Details provided by a digital simulation — discretizing the continuum into millions of mesh points — are infinitely more fine-grained than those provided by experiments — discretizing the continuum into a limited number of measurement points. In addition, simulation is non-intrusive, does not require scaling, can reproduce most conditions (e.g., speed, altitude, temperatures, viscosities, densities, etc.), and can be used in situations that could be too difficult or dangerous to carry out experimentally or in nature.

The ongoing COVID-19 pandemic has accelerated the trend toward simulation during a time in which most, if not all, experimental facilities were closed or reduced in activity. The pandemic has vividly demonstrated that digital technology is the future. Even though the computer revolution started many years ago, the jump in the use of simulation in the last two years has been phenomenal and will inexorably continue to be so.

Controlling Costs with Computational Fluid Dynamics

Consider the three approaches available for the analysis or design of flow-based aerospace products:

- Computational fluid dynamics (CFD)

- Experimental fluid dynamics (EFD)

- Flight fluid dynamics (FFD)

The relative cost of applying each approach is widely different, but nowhere is that disparity greater than for the certification of an aircraft for flying into known icing conditions.

Figure 1 illustrates the orders of magnitude difference in cost when conducting a certification by computer analysis, dry or icing tunnel testing, or by flying the aircraft over a one-month period.

Figure 1. Relative monthly cost of using computational fluid dynamics (CFD), physical testing via experimental fluid dynamics (EFD), and flight fluid dynamics (FFD) in aircraft certification for flight into icing conditions

To this major cost difference you must still add the time savings that can be obtained by using CFD compared to EFD and FFD. This is not to say that each step of a certification or flow-based process could be done by CFD simulation, but that whenever it could be used, its overall cost is minute compared to physical testing by EFD and FFD.

It also goes without saying that the cost of computing will continue to go down as the speed of computers multiply each year with a ratio of two and more. Read about how “The Future is Going to Happen a lot Faster Than the Past Did.”

In the not-so-distant future, the advent of quantum computing will literally introduce a quantum leap in speeds. Simultaneously, the cost of manpower and instrumentation will continue increasing over the years. Assuming a moderate 5% inflation rate (which is being exceeded at the time of writing), even if that inflation rate were not compounded, the cost would be at least 1.5 times higher in a decade while computing would be from two to five times cheaper than today. Thus, migration towards icing and other aircraft certification by computational analysis is gaining speed and is simply irreversible. There is no going back.

Attend the 20th International Icing Course to learn about modern 3D CFD icing methods that are a highly validated and direct extension of CFD aero technologies, using the same grids and very similar algorithms. These are rapidly replacing legacy 2D and 2.5D heuristic methods. Today’s integrated approach to icing calculates aerodynamics (the traditional CFD), water impact, ice accretion, and aerodynamic penalties simultaneously, yielding a comprehensive analysis of the aircraft as a system and not as an assemblage of isolated components. Wouldn’t you want to know what effect an iced Pitot tube would have on the aerodynamic performance of the aircraft, or would you rather design and place that Pitot tube in isolation?

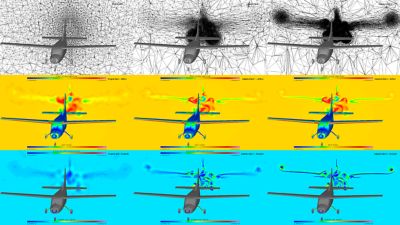

Is completing the aerodynamic design of an aircraft first and then considering icing mitigation solutions a sustainable approach? Absolutely not, especially when icing (water impingement example shown in Figure 2) can be done simultaneously with aerodynamic analysis at the conceptual design phase.

Figure 2. Simultaneous airflow (top) and impingement analysis (below) over a turboprop with propeller running. Automatic mesh optimization is like an auto-focus camera.

A striking example of the need for a combined aero-icing 3D analysis capability is the identification of the critical ice shapes yielding the largest aerodynamic penalties. Two-dimensional calculations may be inaccurate or even misleading, as wings have breaks, sweep, twist, spanwise flows, propeller and engine effects, etc., that greatly affect, modify, delay, or stall its propagation.

The course will demonstrate how reduced-order models (ROMs) can make fully 3D calculations inexpensive and enable rapid identification of aerodynamic and thermodynamic critical points in a structured way and not a heuristic one. In fact, ROMs can yield 3D CFD calculations with 10-20 million points plus impingement, plus icing, plus performance in 1/100 of a second after the calculation of an appropriate number of “snapshots.” This is even faster than 2D calibrated codes!

The inclusion of icing requirements at the aerodynamic design stage yields more comprehensive exploration of the combined aerodynamics/icing envelopes, optimized ice protection system (IPS) design, and focused/reduced wind tunnels, icing tunnels, and flight tests. The end result is faster design, faster testing, faster and more complete natural icing campaign, and a safer aircraft that is easier to certify and free of problems during its life cycle.

This course is structured to be of equal interest to aerodynamicists; icing, environmental systems, and flight simulation engineers; regulators; and designated engineering representatives. Detailed knowledge of CFD is not necessary.

The lectures cover the major aspects of in-flight icing simulation, ice protection systems, handling, and quality issues. The instructors bring an amalgam of knowledge, consisting of scientists and engineers with certification experience who have produced codes in current use and cost-effective simulation methods used internationally for certification of aircraft for flight into known icing conditions.

Attend this course from the comfort of your own office by registering for the 20th International Icing Course, which begins at 9 a.m. EDT Monday, October 24, 2022.