-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

-

ANSYS ADVANTAGE MAGAZINE

January 2021

Lightning Response: Faster Assessment of Aircraft Lightning Vulnerability

By Ansys Advantage Staff

Data from a Brazilian aerospace company indicates that for every 10,000 hours a short-haul regional aircraft flies, it will sustain at least one lightning strike.

For those with a fear of flying, that might be one time too many. But the fact is, while passengers could see a flash or hear a loud noise, chances are the flight will continue safely to its destination. Fortunately, there hasn’t been a catastrophic aircraft event caused by lightning since 1988.1

That’s not to say that transport category aircraft are somehow immune to the impact of lightning strikes, or that the good track record is merely the result of luck. Aviation authorities require manufacturers to engineer lightning protection into every aircraft component and system, then demonstrate they’ve complied with rules and regulations. To assess vulnerability to lightning strikes, aviation engineers have to understand the specific lightning environment for the aircraft. Traditionally, that has depended on performing physical lightning tests, a costly and often cumbersome process.

A manufacturer of civilian and military aircraft used Ansys EMA3D Cable with integrated MHARNESS solver to improve their understanding of aircraft system lightning response and validate a numerical approach to compliance that compared full aircraft simulations to full physical lightning transient analysis (LTA) tests.

A New Approach for Certification

When lightning hits an aircraft, it can produce direct or indirect effects. Direct effects include physical damage to structures and components; indirect effects occur when lightning induces transients into electronics cables, causing a power surge that can disrupt or physically damage flight-critical electronics systems. Although the vast majority of incidents cause only small problems that can easily be repaired, lightning strikes are nothing commercial aircraft manufacturers, regulators or the flying public want to leave to chance. That’s why aviation authorities worldwide have developed strict lightning protection criteria.

As part of certifying an aircraft’s response to lightning, manufacturers traditionally submit results from physical lightning tests, which are done on the tarmac by generating lightning-like energy and injecting it into a test flight vehicle. The process is expensive and complex, requiring special equipment, additional personnel and, often, enough time to reconfigure the aircraft to place the lightning-generating probes in exactly the right spots. Altogether, conducting the test can ground a test plane for as long as a month, gridlocking the schedule if there are other certification tests to be done on the same flight vehicle. What’s more, physical lightning tests can damage the aircraft, resulting in additional delays for repair.

Simulation avoids these types of bottlenecks, but for every simulation effort, the ability of the model to accurately reproduce experimental results must be determined and demonstrated.

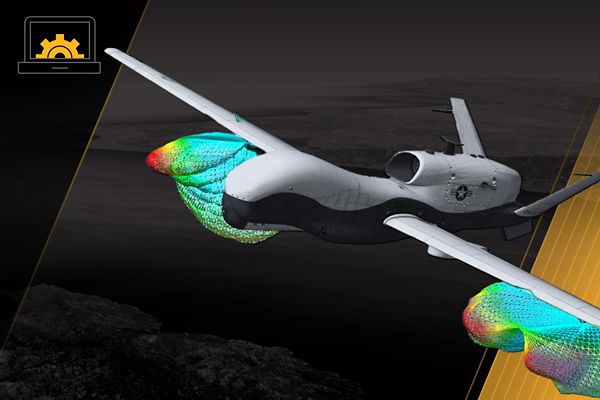

As part of the development of a prototype transport category aircraft, the aircraft manufacturer used Ansys EMA3D Cable with integrated MHARNESS, a cable harness electromagnetic solver, to model lightning’s indirect effects on avionic electronics. They then compared the results against traditional full aircraft LTA tests. These techniques measure the temporary oscillation that occurs in the system because of a sudden change in voltage and currents, and are used in physical testing to establish equipment transient design levels (ETDLs) and aircraft actual transient levels (ATLs) — the amplitudes and waveforms that the systems and equipment must withstand for functionality and safety. The simulation and full vehicle test results closely matched, validating the approach of using computational electromagnetics (CEM) simulation software to determine aircraft ATLs in a manner similar to traditional full vehicle LTA analysis.

Unparalleled Detail and Accuracy

To analyze how lightning couples with the electronics harness — in other words, how lightning finds its way into the collection of cables and wires that runs from the cockpit through the body of the aircraft — the manufacturer first had to recreate a model based on the actual aircraft design. Ansys EMA3D Cable with MHARNESS provided a workflow that allowed engineers to model cable packing in the harness as well as the actual routing and spatial positioning of each cable and wire throughout the entire aircraft. No other simulation software could have replicated the test vehicle configuration with the same level of detail and accuracy as EMA3D Cable did.

Other steps included:

- Determining structural material properties.

- Determining cable properties to understand transfer impedance, a measure of their shielding performance.

- Simulating lightning levels on cables.

- Validating the simulation model.

- Reducing the amplitude of the waveforms to meet the DO-160 lightning protection standard. Waveforms represent how voltage and current change over time. Reducing the amplitude of the waveforms can lessen equipment malfunctions.

Engineers initially prepared the model for inflight configuration but later refined it to match the experimental test configuration.

Lightning Speed Compared to Traditional Testing

The manufacturer achieved a variety of benefits from using simulation to determine lightning response in its new aircraft, including:

- Reducing the scope of expensive aircraft testing.

- Improving test setup and configuration.

- Expanding probe points beyond what is available for physical testing without reconfiguring the aircraft.

- Eliminating the need to reconfigure or modify flight test vehicle components.

- Optimizing cable routing.

- Eliminating test generator noise issues, data acquisition limits and probe implementation effects.

Simulation also reduced the testing period from as much as a month to a fraction of the time, and made it quick and easy to change the design after testing was complete.

Perhaps most important, Ansys solver technology enabled the company to achieve simulation results that were comparable to LTA measurements. Amplitudes were on the same order of magnitude, and waveforms had similar peaks and duration. Being able to produce these results provides confidence in the modeling technique and the parameter inputs and suggests that the simulation approach of predicting lightning transients could be accepted for aircraft certification.

Source

1. “7 Aircraft Disasters Caused by Lightning Strikes,” 24/7 Wall St., LLC, Feb. 21, 2019

讓我們開始吧

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。