簡要規格

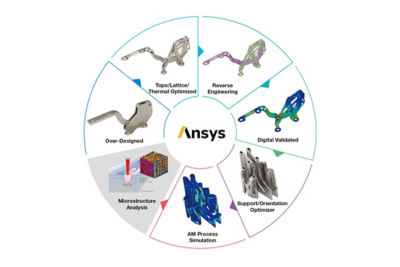

Ansys Additive Suite 是一套完整的工作流程解決方案,能提供設計師、工程師和分析師所需的關鍵見解。從積層製造 (DfAM) 的設計、驗證到列印設計等等,此解決方案橫跨整個工作流程,有助於避免建立故障,並提供準確設計的零件。

產品系列

查看所有產品Ansys致力於為當今的學生打下成功的基礎,通過向學生提供免費的模擬工程軟體。

With Ansys Additive Suite, users have access to all Additive tools, including Additive Prep, Additive Science and Workbench Additive.

Critical insights required for a successful Additive Manufacturing workflow

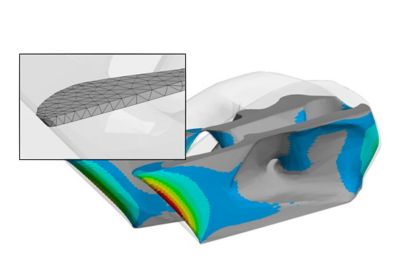

A comprehensive solution for designs, engineers and analysts, Ansys Additive Suite spans the entire workflow – from design for additive manufacturing (DfAM) through validation, print design, process simulation and exploration of materials.

Additive Suite includes Additive Prep and Science tools, in addition to access to Ansys Workbench Additive.

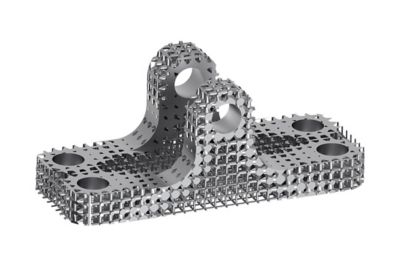

Hyundai engineers used were tasked with re-designing the hood hinge for their vehicles. They chose Ansys as a one stop solution for taking them through Design, Analysis, Product Verification, Process Verification and Production using Additive Manufacturing. This design was also won the grand prize for the 3D Printing DfAM Competition inside Hyundai.

Ansys Additive Suite 是一套完整的工作流程解決方案,能提供設計師、工程師和分析師所需的關鍵見解。從積層製造 (DfAM) 的設計、驗證到列印設計等等,此解決方案橫跨整個工作流程,有助於避免建立故障,並提供準確設計的零件。

ADDITIVE SUITE CAPABILITIES

Avoid build failure and create parts that accurately conform to design specifications with Ansys Additive Suite. Delivering critical insights for designers, engineers and analysts, this comprehensive solution spans the entire workflow.

With Additive Suite, users gain access to Additive Prep and Science tools, in addition to Ansys Workbench Additive.

Ansys Additive Suite is available as an add-on to the Ansys Mechanical Enterprise license.

Enhance your Additive Manufacturing with:

對 Ansys 而言,所有人皆能使用本公司產品非常重要,身心障礙者也不例外。因此,我們致力於遵循美國無障礙委員會 (第 508 節)、無障礙網頁內容規範 (WCAG)、自願性產品輔助工具範本 (VPAT) 當前格式等各項無障礙需求。

如果您面臨工程挑戰,我們的團隊將隨時為您提供協助。憑藉豐富的經驗和對創新的承諾,我們邀請您與我們聯絡。讓我們共同合作,將您的工程障礙轉化為成長和成功的機會。立即與我們聯絡,開始對話。