ANSYS ADVANTAGE MAGAZINE

July 2021

Steering the Future of Mobility with Composites

By Francesco Fiorini, thyssenkrupp Presta AG; Fabio Pavia, Ansys; Slav Dimitrov, CADFEM GmbH; and Federico Negri, Ansys

All products have an environmental impact, a fact customers are increasingly aware of as they take an interest in their carbon footprints. In the automotive industry, there is a global push to reach zero vehicle emissions by 2050 to satisfy consumer demand and increasingly stricter environmental laws. To do so, leading vehicle manufacturers and their partners are embracing lightweighting and electrification. Composite materials are key to making vehicles lighter so they can use smaller engines that consume less energy and produce fewer emissions.

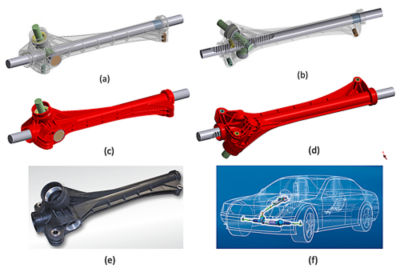

Figure 1. The servo-assisted steering system developed by thyssenkrupp Presta. (a) and (b) details of the steering system mechanics; (c) and (d) in red the reinforced-plastic steering housing; (e) photo of the manufactured plastic steering housing; (f) servo-assisted steering system within the vehicle. The integrity of the servo-assisted steering system housing is critical to ensure the safety of the vehicle occupants. Images courtesy of thyssenkrupp Presta.

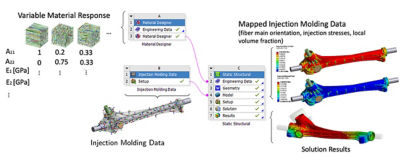

Figure 2. Workflow for building the multiscale model in Ansys Mechanical with the help of Ansys Material Designer

The principal applications of composites in the automotive sector are for under-the-hood components and exteriors, using prepreg (carbon or glass fibers laminates), typically in luxury and medium-volume cars. However, for the high-volume production models, an increasingly adopted technique is the manufacturing of safety and structural critical components through injection molding with short-fiber reinforced plastics. Body panels, frames, housings, support structures, bumpers and seat structures are all being manufactured with short-fiber reinforced plastics. With the growth of electromobility, the demand for lightweight components is expected to rise even more.

Injection molding is an ideal process for fabricating large numbers of geometrically complex parts. Many everyday items from sectors beyond automotive are injection-molded: mobile phone housings, television cabinets, compact discs and lunchboxes are just a few examples. An essential characteristic of injection molding is that it may not be possible to fix a part defect in production by simply varying process conditions. Frequently, the mold must be modified to overcome a problem. This is expensive and costs valuable time. It is far better to avoid problems in the design phase than to fix them in production. Furthermore, injection molding is strongly dependent on the ability to precisely predict the mechanical behavior of the processed parts in the application, and to accurately reproduce their microstructure, which varies throughout the parts influencing the local material properties. Simulation of the structural response of injection-molded plastic parts is highly valuable to industry.

Fiber-Reinforced Plastics Workflow

In fiber-reinforced plastics, the geometry, volume (or mass) fraction, thermo-mechanical properties, orientation distribution of the fibers, and the polymer matrix’s thermo-mechanical properties significantly affect the mechanical and thermal performances of the composite material. Therefore, the idea of material modeling for predicting the macroscopic behavior of the injection-molded composite materials from the mechanics and physics at the microscopic level is becoming increasingly important.

One example of a product design and development workflow for fiber-reinforced plastics available within Ansys comes from thyssenkrupp Presta AG, whose injection-molded housing for a servo-assisted steering system is made of short-fiber reinforced glass-fiber composite.

Located in Liechtenstein, thyssenkrupp Presta AG is a first-tier OEM supplier for the automotive industry and it belongs to and is the management company of the thyssenkrupp Steering business unit of the German conglomerate thyssenkrupp. thyssenkrupp Presta AG is investing heavily in research and development to face the new trends that are overhauling the automotive industry. Its core focus is in the chassis area, particularly in electric-powered steering and steer-by-wire systems. thyssenkrupp Presta AG uses Ansys Mechanical to create 3D digital twins of the components and optimize them to bring extreme reliability to its customers. Nine out of 10 premium-class cars include components from the company and, in general, one out of four vehicles in the world has thyssenkrupp Presta AG technology inside.

Figure 3. The main fiber directions are shown in red, mapped to the meshed geometry of the plastic housing using the orientation tensor in output from the injection molding simulation.

Shift to a Reinforced-Plastic Steering Housing

In the last decade, there has been a technological change in the steering market from steering systems with hydraulic assistance to steering systems with electrical assistance. Besides gear components, the steering housing is one of the most high-load components, which is why it is traditionally made of aluminum. The technological change toward electrically assisted steering and the further development of affordable high-performance plastics have resulted in a multitude of new application possibilities.

The housing element of a servo-assisted steering system produced by thyssenkrupp Presta AG, which was originally made of aluminum, was substituted in the new design by an element of similar shape made with glass-fiber-reinforced high-performance plastic. The challenges included developing the plastic-compatible design, and meeting both OEM specifications and price expectations.

The servo-assisted steering system, the plastic housing and its location within the vehicle are shown in Figure 1. The steering support is provided by the power assistance located on the steering column. Metal inserts are used for highly stressed areas at several screw connections of the steering gear. The glass-fiber reinforced plastic is characterized by high resistance to all typical engine compartment reagents. It has good aging properties, with negligibly small changes in toughness and tensile elastic modulus. However, different from isotropic metals, this new material is not only anisotropic but also heterogeneous, thus anisotropic properties are dependent on the microstructure, which varies locally because of the injection molding process. Therefore, simulating the stress distribution in the housing element under the corresponding workload is a real challenge for a simulation engineer.

Figure 4. Total displacement in the case scenario for the anisotropic and Isotropic (simplified) model. The same color bands are used for both models.

Meeting the Simulation Challenge with a Multiscale Model

Multiscale techniques have traditionally encountered a limited application in modeling the mechanics behavior of fiber-reinforced plastics because of large memory and computing power requirements for such simulations. Recently, Ansys Material Designer has enabled a multiscale modeling approach for short-fiber composites with a lower computational demand. The evaluation of homogenized material properties for all the possible microstructural configurations (stored in a variable material data) is decoupled from the subsequent assignment to the finite element representation of a plastic part (see Figure 2), which is realized in the downstream analysis according to the given microstructure (fiber orientation tensor) locally present in the part as a result of the manufacturing process. This local fiber orientation state can be imported from injection simulations or experimental CT scan data. While evaluating the possible microstructures in Material Designer, the nonlinearities of the material response are captured through a phenomenological strain-rate–independent model combining an orientation-dependent anisotropic Hill yield criterion with a nonlinear isotropic hardening law, both fitted against experimental data in accordance with the ISO 527 standard.

This variable material response as a function of all the possible orientations is then combined in Mechanical with the local fiber orientation imported in Ansys Workbench through the Injection Molding Data system, an interface that allows the user to import text-based orientation data files of injection molding simulations into the Ansys simulation environment. The injection process data is parsed, processed and then transferred to a downstream Mechanical system where it is applied in the form of element orientations as shown in Figure 3. During the mapping process onto the Ansys mesh of the plastic housing, the team considered the principal fiber directions and the two largest eigenvalues of the fiber orientation tensor. Additionally, local variation of the nominal fiber volume fraction and the presence of injection stresses can be considered but were neglected here.

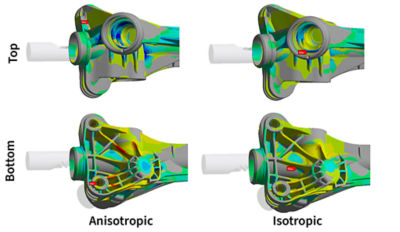

Figure 5. Effective stress analysis in the case scenario for the anisotropic and isotropic (simplified) model. The same color bands are used for both models. The stress patterns appear different in the two models, in particular (as the anisotropic model highlights), the ribs at the bottom of the housing and one of the attachment points. Note the change of critical location between the anisotropic and the isotropic model.

More Accuracy Without More Simulation Time

The simulation where the steering housing was accurately modeled as anisotropic and accounting for the local fiber orientations was compared to a simulation where a simplified equivalent isotropic material model was applied to the housing, thus neglecting the presence of the local orientation of the reinforcing fibers. For the equivalent isotropic material, material properties are those where the fibers have a fully randomized orientation. This is a very common engineering approach, usually followed in absence of specialized workflows like those available within Ansys and used here within the more accurate anisotropic material model.

As shown in Table 1, the use of the more accurate workflow for short-fiber reinforced plastics does not increase significantly the computational burden of the simulation in terms of solution time, memory needed or size of the result files required by Ansys. However, the simplified isotropic model behaves as excessively compliant (Figure 4), with 50% higher values of predicted maximum deformation when compared to the displacement values shown by the anisotropic model.

Figure 5 contains plots of the effective stress results obtained for the same geometry, but the two different types of material models are considered in the analysis for the housing. It is evident that with the higher stiffness of the anisotropic model, internal stresses become fixed inside, have higher values and influence the strength of the housing more. Effective stresses at the critical locations (in red in the figure) appear 40%–50% higher in the anisotropic model when compared to the simplified isotropic one. Taking into account the elasto-plastic anisotropy and the heterogeneity in the distribution of local fiber orientations significantly changes the critically loaded material points, with the results shown for the more accurate model correctly capturing the physical reality as has been verified by experimental tests conducted by thyssenkrupp Presta AG.

These results show that the use of the workflow for short-fiber reinforced plastics leads to more realistic results and prevents a gross underestimation of the stress level in the steering housing and overestimation of the deformation in the steering system in the simulation load case scenario, which would be possible with more common simplified engineering approaches. The greater accuracy of the Ansys workflow for fiber-reinforced plastics only minimally increases the computational requirements for such complex multiscale simulations. The Ansys software helped thyssenkrupp Presta AG to reach the targeted 50% weight reduction with respect to the original metal part and to assess all the mechanical performance and OEM requirements.

Using Ansys gave thyssenkrupp Presta AG confidence in plastic housing design even before its actual manufacturing. The adoption of an innovative and lightweight plastic housing for its steering system supports both the ecological and the economical goals of thyssenkrupp Presta AG and helps the company lead the evolution of steering systems for the automotive market of tomorrow.

시작하기

엔지니어링 과제에 직면하고 있다면우리 팀이 도와드리겠습니다. 풍부한 경험과 혁신에 대한 헌신을 가지고 있는 우리에게 연락해 주십시오. 협력을 통해 엔지니어링 문제를 성장과 성공의 기회로 바꾸십시오. 지금 문의하기