-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

什么是电子产品热管理?

电子产品热管理是一门工程学科,其重点是高效管理电子设备及系统中的热量。其利用热传导、对流、辐射和热力学的物理特性,将组件温度保持在可接受的工作范围内。如果不加以控制,温度就会升高,电子组件性能就会下降,而且某些部件可能会出现故障。此外,器件和封装之间的连接也会削弱,甚至断裂。每当您听到笔记本电脑风扇启动或感受到手机背面发热时,就是热管理在发挥作用。

电子设备通过电路和电子组件传递电流来工作。电线、PCB导线、连接、芯片封装和组件都会在电流流经电路时发热。如果没有有效管理热量,电子设备各区域的温度就会上升,从而改变材料属性。这些属性改变可能会导致多种问题,其中包括电阻增大、机械强度降低、信号失真以及最终的产品性能下降和不良的用户体验等。此外,材料还会热胀冷缩,对组件造成热应力,从而导致组件或系统的机械故障、疲劳和过早老化。

从手机和电动汽车到为卫星上的CMOS摄像头散热,热管理在当前电子应用的整体性能和鲁棒性方面发挥着重要作用。因此,全面了解可选择的方案至关重要。热管理应用已成为产品开发的关键部分,应纳入设计流程的每一步。

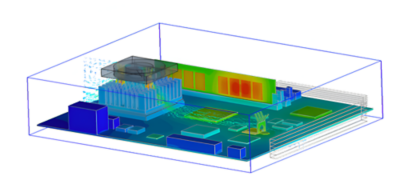

电子产品外壳的温度分布

不同类型的电子产品热管理系统

在讨论如何处理多余热量的具体内容之前,我们需要了解,在工程师选择热管理方法时,电子系统的规模是一项关键影响因素。半导体芯片封装面临的发热和散热挑战,与印刷电路板(PCB)有所不同。与之类似,具有多个PCB和其它热源(如电源)的外壳,需要与机架或整个数据中心等装配体不同的解决方案。这些解决方案,可分为芯片级、组件级、电路板级及系统级热管理解决方案。

另一个重要的区别是被动热管理和主动热管理。不使用电源的电子产品散热方法,被称为被动散热解决方案。主动散热解决方案使用电源(通常为电力)来提高对流流体的速度,或为热力学或热电装置供电。被动散热通常是首选方法,因为其不消耗能量,没有活动部件,而且更具成本效益。不过,考虑到被动散热管理方案永远无法将设备温度降至环境温度以下,又或者被动系统不具备所需的热性能,因此,设计中还会包含主动系统。

下面是目前最常用的高效热管理方法,分为被动及主动解决方案。

被动热管理方法

热界面材料(TIM):组件之间及组件周围的材料,用于将这些组件与高温隔绝,也用于将热量从热源散出。在灌封和封装中,各种丙烯酸、环氧树脂、硅树脂和聚氨酯树脂涂层会完全封闭组件、装配体或整个设备。粘合剂、凝胶和润滑脂等组件之间的其它类型材料,可在元件之间提供高热导率。

热扩散器(Heat Spreader):将热量从热点传导至较冷位置或另一个热管理解决方案的物体。半导体封装、PCB或电子产品外壳的几何结构和材料可将热能从热点散出。在封装和电路板层面使用球栅阵列、导线、过孔和接地层。在外壳中,来自电路板和电力电子产品的热可通过紧固件和楔锁直接传递至外壳或其它热管理器件。

自由对流:最常见且最具成本效益的散热机制是高温物体周围的空气的自然对流。由于热空气会因浮力的作用而上升,热物体的热能会进入空气中,然后上升并离开部件,从而将较冷的空气吸入,取代热空气。空气是自由对流中最常见的流体,但在要求更严苛的应用中,会使用其它气体和液体。

散热器(Heat Sink):附着在热源上的一个物体将热量从源物体传递出去,然后通过对流传热的方式将其耗散在流体中。散热器设计可最大限度增大对流流体可吸收热量的表面积。散热器最常见于CPU、电力电子组件和激光器等热源上。

热导管:使用挥发性物质的相变从热源吸收热能的装置。能量可将液体转化为蒸汽,蒸汽沿着热导管到达另一端,在这里蒸汽会冷凝并返回热端重复循环。

红外辐射器:使用红外辐射将热量从平板上传递出去的大型金属平板。其包含热幅射器,用于无法将热量从系统中对流或传导出去的应用,通常应用于太空环境。

主动热管理方法

强制对流和强制风冷:使用风扇或鼓风机在组件或散热器上产生气流的供电装置。较高的气流速度可增强对流传热,从而可从物体中吸收更多热量。

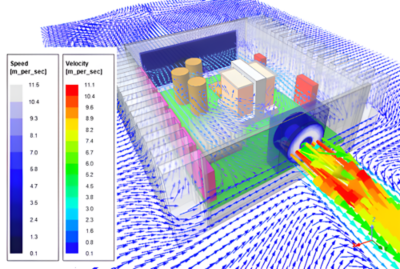

电子产品外壳内的对流传热

液冷:一种热管理方法,其中液体会流经热源来吸收热量,并将其从热源中散出。液冷通常使用强制对流或热交换器(辐射器),在液体返回热源之前对其进行冷却。液冷的常见应用示例包括高性能计算机、电池系统、电机和电动汽车。

射流冲击冷却:高效的散热解决方案,通过喷嘴将流体喷射到热源上。更高的流速、湍流以及冲击表面有时发生的汽化,会显著增加从物体到流体的热传递。

喷雾冷却:一种类似于射流冲击冷却的方法,但不是流体喷射,而是将冷却剂雾化成小液滴,当它们碰到热源时就会蒸发。这种相变吸收的能量,比对流要多得多。

制冷:利用蒸汽压缩热力学,循环使用压缩、冷凝、膨胀和相变从热源中吸取热量。环境温度远高于电子设备所需的工作温度时,这种方法尤为实用。数据中心,是利用制冷来为自由对流、强制对流及液冷系统的工作流体散热的一个常见示例。

电阻加热:大多数热管理方法都是为了电子系统或组件散热。但在某些应用中,设备在极冷环境下工作,工程师需要在其设计中纳入电阻式加热器,以将温度提高到可接受的工作范围。在太空电子产品、某些汽车电子产品以及各种在极端环境下工作的物联网(IoT)应用中,电阻式加热器很常见。

热电散热:这种热管理固态设备,利用Peltier效应将电能转换为热能。电流通过两个不同的半导体材料,会导致一端的温度升高,另一端的温度降低。这个较低温度端可直接连接至需要散热的电子组件。

将热管理设计到电子系统中的流程

从微小的微型芯片到海量数据中心,设计电子系统的工程师必须探索系统的热行为,然后选择相应热管理解决方案——需要符合系统热性能标准、具有成本效益,而且不会产生与系统电气或机械要求有关的问题。

热管理设计通常应该集成到整体产品设计流程中,尤其是以仿真为导向的设计流程。以下技术有助于开发团队了解应用,以快速进行权衡并优化解决方案。

组件特征描述

要获得有效的热管理解决方案,首先要了解系统的组件的热属性。设计团队应该先收集技术信息,例如系统中每个电子组件及机械组件的几何结构、材料属性、发热、热容量、标准工作条件以及可接受的工作温度等。

这些值可从供应商那里获得,或者您可能必须进行热特征测试。为了估算散热量,电气工程师通常会根据组件产品说明书中列出的电气行为运行电路模型。此外,还可利用仿真来确定组件和互连中的允许热应变,或描述组件装配体的热行为特征。

环境评估

一旦团队知道了电子系统内部的情况,他们就需要了解系统的工作环境。

消费类电子产品的散热解决方案与航空电子设备中的热管理解决方案截然不同。

比如,避免智能手机过热的解决方案,受到机身内部空间的限制,唯一可以散热的地方是设备周围的空气;而战斗机上的航空电子设备包具有高压,且有冷空气可以吹入外壳。工业物联网设备可能无法接触到低温环境、冷空气或水,因此,机载热电制冷器可能是该应用的最佳解决方案。同样,特定行业的标准和法规可能会最终决定可使用的热管理方法。

热仿真

鉴于各种不同的方案选项以及对不同需求的权衡,仿真成为了开发热管理解决方案的理想工具。

在半导体芯片封装层面,设计人员可以迭代封装方法、热焊点及热通孔的位置,以及接地层的厚度。

另一方面,在更大尺度的应用中,可以使用计算流体力学(CFD)对数据中心内部和整个楼层机架周围的气流进行建模和优化。

Ansys Icepak®软件是专为电子产品散热设计的CFD解决方案的绝佳示例,主要用于组件、封装、电路板和外壳层面。工程师能够直接导入设计,并快速对热管理解决方案进行建模。在芯片层面,工程师将Ansys Redhawk-SC Electrothermal™软件作为2.5D和3D-IC系统的签核解决方案。Redhawk-SC Electrothermal软件与Icepak软件相结合,可实现系统感知芯片设计。

工程师需要管理的另一个热源,是电子应用中电磁产生的热量。大功率天线等高频应用中,会因电磁波传播的介质损耗而产生热量。Ansys HFSS™软件等工具可预测所产生的热量,随后可将其用作热仿真的边界条件,用于优化整个电子装配体中的热管理。

同样,手机、智能手表和VR头戴式显示器等消费类电子产品中的低频应用(如电机、电源和无线充电)也会产生热量。在电子产品热管理解决方案仿真中,Ansys Maxwell®软件可以对这些损耗进行建模,并提供准确的热源值。

一旦通过仿真或测试完成组件及装配体设计表征,就可以在系统层面将其表示为降阶模型(ROM),并且可以在Ansys ModelCenter®软件等工具中探索和优化整个散热系统。工程师随后可进行权衡研究,为多种使用案例确定最佳热管理方法。

散热方法选择

在了解内部配置和外部环境并通过热仿真对组件和系统进行建模后,团队就可以开始进行迭代、选择合适的散热方法,对许多不同的方案进行虚拟评估。

电子产品热管理的未来

看似无关的技术进步,也将影响热管理未来,其中一个良好示例是近来人工智能(AI)的蓬勃发展。大型语言模型(LLM)使用大量的GPU,这为大型数据中心的散热技术带来了热管理难题。

随着数字世界的扩展与发展,对高功率高速电子产品的需求将继续推动热管理的创新发展。在这一趋势的推动下,人们把目光投向了更高效的制冷解决方案、喷流散热优化、更有效的热电设备,以及浸没式散热等先进散热策略。

高性能计算应用将推动解决方案发展,同时,组件和系统的持续小型化正在推动行业进行另一个层面的发展。热晶体管是一个激动人心的新研究领域。这些晶体管可根据需要控制热流,从而有可能将散热定向到所需的位置,而不是为整个芯片散热。

仿真功能和效率的持续发展,是热管理领域最有效、最具影响力的改进。这类软件将集成AI,改进其与设计系统的集成,提高用户工作效率,并进一步结合物理特性,同时充分利用其带来的更高算力。

相关资源

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。