-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

February 13, 2018

Improve Thermal Reliability with Ansys Icepak

Electronics is at the heart of many exciting products like smartphones, tablets, and TVs, and it plays a key role in various industries from semiconductor, automotive, agriculture, aerospace, entertainment to healthcare. Modern electronic devices are faster, smaller, and denser than ever before. Since we pack millions of transistors within a small area, these devices tend to generate a lot of heat. Heat-induced mechanical effects, such as delamination, and breakage of solder joints connecting the chips to their printed circuit boards (PCBs), can cause system-wide reliability problems. It’s critical to simulate the electro-thermal and structural properties of electronic designs before you build the hardware. Simulation tools from Ansys can solve these challenges and improve the reliability and performance of electronic products.

Consider graphics cards (aka GPUs) — we are seeing manifold expansion of their uses in several applications. The overall desire for high-quality images, by hardcore gamers and people watching movies on high-end monitors and televisions, drives the demand for dedicated graphics cards. Cryptocurrencies are pushing up the demand for GPUs due to their ability to quicken the process of minting crypto-coins. Besides graphics and bitcoin mining, GPUs are also being used for high performance computing, machine learning, computational finance as well as automated driving/advanced driver assistance systems (ADAS).

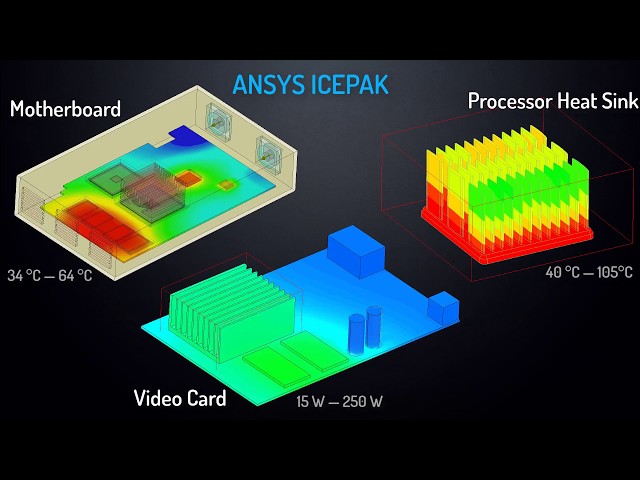

Essentially, a graphics card is a PCB that has its own processing unit (often with hundreds of compute cores) and high-speed DDR memory. As with any electronic device, problems related to graphics cards can be categorized as electrical, thermal, and mechanical. In addition to the heat produced by the chips themselves, current flow within the power planes and traces on the card can cause ohmic heating, leading to thermal-induced problems. Ansys Icepak can predict these thermal issues on a virtual prototype long before you manufacture the graphics card. You can perform standalone thermal analyses and Multiphysics electro-thermal simulations in Icepak. As an integral part of Ansys Electronics Desktop, Icepak works together with electromagnetics (EM) solvers in a unified environment. It offers powerful features in a user-friendly interface and a convenient library of commonly-used thermal components for solving thermal issues of electronic devices.

Ansys Icepak lets you easily import electrical CAD (or ECAD) layouts and mechanical CAD (or MCAD) models of components. You can easily add 3D components like fans and heat sinks from its built-in library. You can run parametric simulations to study the effects of varying power levels in the components. Icepak can perform maximum power analysis and predict safe operating temperatures of the graphics card and its components before they experience possible thermal-induced breakdown. Whether you want to develop mid-range or high-end video graphics cards, you can simulate these devices in Ansys Icepak before committing them to the manufacturing process. Ansys Icepak will help improve reliability and performance of these products and reduce the cost associated with their build and test.

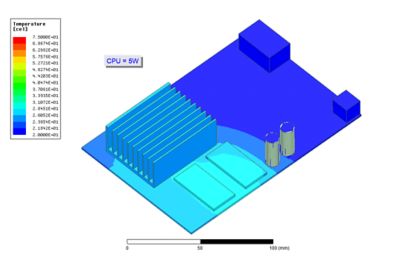

Maximum power analysis of a CPU on a graphics card in Ansys Icepak

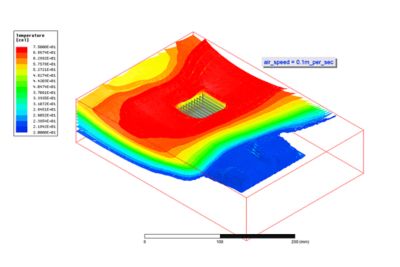

Thermal simulation of a graphics card in Ansys Icepak

Ansys Icepak is the premier electronics cooling solution for ICs, packages, PCBs, computers, and data centers. In addition to standalone thermal analyses, you can couple Icepak with EM products like HFSS, Q3D Extractor and Maxwell for electro-thermal simulations of antennas, power electronics and electrical machinery.

Listen to contributing author J. Eric Bracken, Ph.D. (Chief Technologist, Ansys Electronics Business Unit) explain how you can use Ansys Icepak to improve thermal reliability of electronic devices.