规格速览

由LS-DYNA求解器提供支持的Ansys Forming可提供综合全面的平台,以满足您的所有金属冲压需求。Ansys Forming能够通过预设方案监控成形过程的各个阶段,包括可行性、成形性和回弹,从而推动早期阶段和详细设计方案的优化。

Ansys Forming能够通过端到端工作流程仿真所有金属冲压任务,该工作流程允许您在统一平台上执行完整的模具工艺,并且最大限度提高求解速度。借助Ansys Forming,您可以实现最佳性能,保持速度和准确性,并通过减少模切和重新设计来提高生产力和节约成本。

由LS-DYNA求解器提供支持的Ansys Forming可提供综合全面的平台,以满足您的所有金属冲压需求。Ansys Forming能够通过预设方案监控成形过程的各个阶段,包括可行性、成形性和回弹,从而推动早期阶段和详细设计方案的优化。

2025年7月

Ansys Forming 2025 R2版本凭借一步式分析、更优的拉延筋力预测以及新的材料模型,提升了成形准确度和工作流程效率。

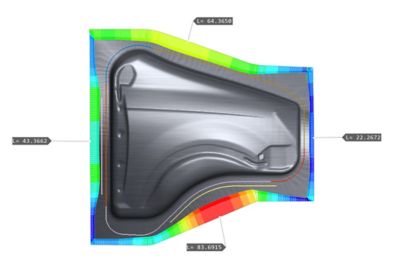

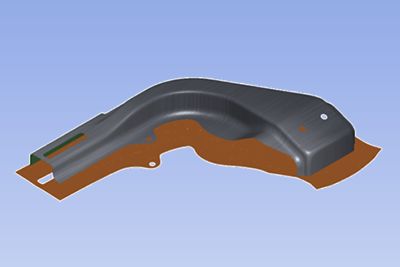

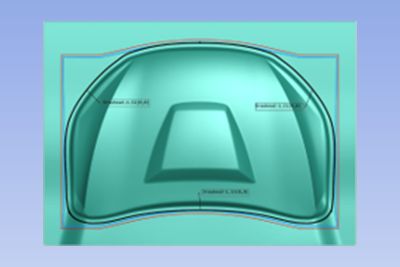

Ansys Forming通过全新一步式分析加速早期仿真。该软件提供支持压料控制、自动网格重新划分以及部件重新定位等功能,可在进行完整的增量仿真之前,快速高效地估算成形历程并优化流程。

提供了一种新方法,可增强2D拉延筋约束力及 挺举力的计算,从而可提供即时准确的力预测。该增强功能可显著提高增量成形历程的准确性,支持可靠性和效率都更高的钣金成形仿真。

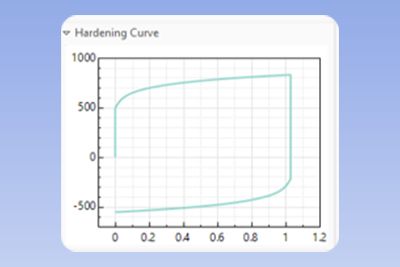

更新的材料库现在不仅支持运动硬化模型,而且还允许直接输入用于Barlat 2000屈服准则的测试数据。这些增强功能,可为一系列更广泛的材料实现成形历程的准确仿真,从而提高不同成形应用的可靠性。

要让包括残障人士在内的所有用户都能访问我们的产品,这一点对于Ansys而言至关重要。因此,我们始终致力于遵循基于美国访问委员会(第508节)、Web内容可访问性指南(WCAG)和当前自愿产品可访问性模板(VPAT)格式的可访问性要求。

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。