-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

May 17, 2021

How to Efficiently Optimize Electric Motor Design

The electric machine design industry has developed rapidly in recent years, largely driven by the electrification of transportation, and mostly in response to environmental and natural resource concerns. For electric motor designers, this translates into a new set of challenges. Motors should be more efficient and more compact with sufficient output power and torque density levels. They should also be designed for mass production, especially for aerospace or automotive applications.

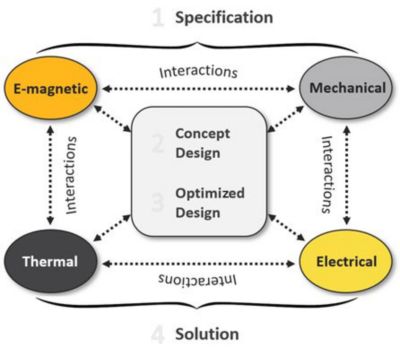

On top of that, motor designs need to be developed in a short timeframe and as part of a wider complex system, such as powertrains in autonomous vehicles. At motor level performance, we have to account for different physical domains that interact with each other throughout the design process.

The design of electric motors is multidisciplinary.

Steps to Electric Motor Design

Electric motor analysis starts with specification requirements, then enters the preliminary design phase with the goal of finding a concept design for further optimization. The initial design is then optimized with specific constraints and objectives. In the last steps, decisions are made regarding the optimal solution, finding a compromise between conflicting performance criteria.

Learn more about Electric Motor Optimization with Ansys Motor-CAD

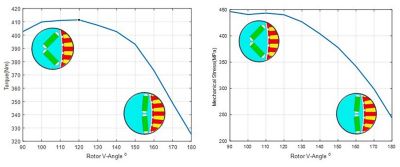

For example, if you have an interior permanent magnet (IPM) motor with one layer of V-shaped magnets, increasing the angle between the two magnets forming a pole tends to reduce the output torque capability of the machine. At the same time, this also reduces the maximum stress within the rotor structure at high-speed operation. We have a clear trade-off between the peak performance at low speed and the rotor structural integrity at higher speed.

We need optimization analysis to figure out the most optimal trade-off scenario.

Interior permanent magnet (IPM) motor with one layer of V-shaped magnets where increasing the angle of two magnets reduces the output torque capability, as well as reducing the maximum stress within the rotor structure at high-speed operation.

Efficient Optimization Workflow for Electric Motors

For an efficient optimization workflow, we need a multiphysics analysis. The machine’s performance needs to be evaluated across the full speed range. We need to know the performance at low, medium and high speed, and to understand how this performance is affected within the design space.

A design space is usually quite large, and there are interactions between the independent variables for which we’re seeking optimizations strategies. To summarize: We’re looking for optimization strategies that include the multiphysics design characteristics of the machine over the full speed range.

We also look for workflows where we can rapidly trade off the machine performance and evaluate the impact of any change of specification requirements, while keeping track of design decisions.

Try Ansys Motor-CAD for step-by-step electric motor optimization workflow.

Surrogate model-based optimization strategies perfectly fulfill these requirements. The workflow typically consist of 4 main steps:

- Sensitivity analysis

- Metamodel generation

- Optimization algorithm

- Validation

A meta-model based optimization workflow

We start with a sensitivity analysis. This stage starts with a variation study that consists of extracting performance datasets across the design space in place. Extracted data are then analyzed to evaluate the sensitivity of every output parameter to input variable changes.

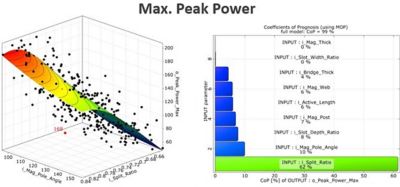

Next, sensitivity data are used to build metamodel of optimal prognosis (MOPs), showing the optimal subspace for every optimization relevant output.

If we focus on specific performance output – say, the maximum peak power and the maximum continuous torque – we can see how these outputs vary within the design space and which variables have the biggest impact. We see that the continuous torque at low speed is highly affected by a change in length while the peak power is mainly affected by the split ratio. From that, we can already trade-off some conflicting performance in the machine design.

Metamodel of optimal prognosis (MOP) showing the maximum peak power

Metamodel of optimal prognosis (MOP) of the maximum continuous torque at low speed

Finally, an optimizer is applied directly to the surrogate models with given goals and constraints. If the optimization is multiobjective, then the best results can be interpreted using a Pareto front that shows how the objectives may conflict with each other within the solution space.

The last stage of the workflow is the validation, where the metamodel based optimization results (obtained from an optimizer applied on response surface functions), are validated against final Ansys Motor-CAD runs.

Electric motor design optimization is a complex, multidisciplinary and often non-linear problem. It involves multi-objective and multi-constraint scenarios where an engineer has to evaluate design tradeoffs necessary due to conflicting performance.

Ansys Motor-CAD is a leading electric motor design tool combining analytical and finite element analysis (FEA) methods for fast and accurate performance prediction of electric motors. It enables multiphysics simulation across the full operating range. Motor-CAD, combined with Ansys optiSLang presents an opportunity for unprecedented optimization strategy, enables system level tradeoffs and allows electric motor designers to quickly experiment with changes to specification with respect to the design space.

To learn more about how to optimize electric machines, request the on-demand webinar: Designing an E-Machine: Optimizing Electric Machines with Multiphysics Analysis.