-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

September 1, 2023

Charging Through Electric Motor Development with Simulation

In the shift toward electrification, consumers are clearly aware of the challenges that come with this relatively new and emerging technology, including driving range and the charging infrastructure needed to support long-distance travel. Batteries are a key element in the rapid adoption of electric mobility, as they directly impact how far electric vehicles (EVs) can go on a single charge. However, EVs — and hybrid EVs, for that matter — are really driven by not one, but three important enabling automotive technologies: e-drives, batteries, and vehicle control systems.

Electric motors play an important role, as they use electromagnetic forces to convert electricity from the battery into mechanical power that sets a vehicle in motion. However, not all of the energy collected during charging is captured and used during this conversion. Some of it is lost due to heat or friction. So, for original equipment manufacturers (OEMs), the goal in any electric motor design is to achieve maximum energy efficiency to ensure most of the power from the battery is used by the electric motor to extend vehicle range. To do this requires an understanding of the physics behind a given design, enabled by simulation-driven engineering.

Dr. Helmut Schmid knows a lot about electric motors. He works in the Advanced Development Department of ZF Friedrichshafen AG, a global technology company and systems supplier of electric drives for passenger and commercial vehicles. Dr. Schmid’s focus is on simulation, specifically on how to improve Ansys-enabled simulation frameworks and workflows to deliver sustainable solutions to individuals involved in the core development of ZF’s electric motor technology.

“ZF is automating development for all characteristics of electric motors related to electromagnetic, thermal, and mechanical domains,” says Dr. Schmid. “Our goal is to continuously deliver software solutions and provide novel methods and tools which can be used by our stakeholders all along the development process.”

ZF engineer using Ansys software

Taking Charge of the Mobility Narrative with Novel Solutions

At the moment, ZF is enabling the next generation of mobility by developing systems and components they say can “see, think, and act” through hardware, software, and sensor technology. It offers a comprehensive solution that extends to vehicle motion control, integrated safety, autonomous driving, and electric mobility to help advance more sustainable transportation.

To this end, Ansys simulation helps ZF to develop electric motors and related products for high volume at an affordable cost, all while delivering the simplest functionality required to best address OEM requirements. Using simulation, Dr. Schmid’s team can standardize development on the product side, as well as the simulation side to find greater efficiencies.

“We developed a modular kit for our electric motors, with a specific focus on commonality of parts which can be shared among different electric motors,” says Dr. Schmid. “With simulation, we could address requirements to achieve standardization throughout our product offerings. We have also standardized our simulation processes to successfully reduce efforts across development departments.”

ZF's electric motor is uniquely compact due to its innovative rotor design: the energy for the magnetic field in the rotor is generated by coils whose current is transmitted via an inductive exciter inside the rotor shaft.

Benchmarking Innovation with Simulation

Benchmarking competitive components is a big part of ZF’s design workflow — activity efficiently accomplished by Ansys simulation. Not only does this activity apply to electric motors, but extends to other aspects of an electric powertrain, including inverters. Inverters are electronic devices critical to the conversion of electricity from DC to AC output required to power the motor.

In one instance, ZF’s inverter team looked to Ansys Q3D Extractor for parasitic extraction (PEX), or the calculation of the parasitic effects or frequency-dependent characteristics of their designs. Parasitic extraction is an important part of electronic design automation, as it helps the team create an accurate model of the circuit to enable detailed simulations of circuit response.

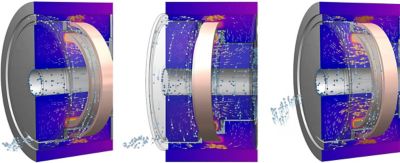

Fluid, thermal, and electromagnetic simulation of an inductive exciter unit for ZF's Separately Excited Synchronous Motor (SESM)

The model is then passed through Ansys Maxwell to precisely characterize the motion of the electromagnetic components, and their effects on overall design. From there, a fully parametric (statistical) model can be realized, then worked on in Ansys Twin Builder via Ansys Electronics Desktop connected to an electromagnetic simulation. This activity is followed by a transient simulation to extract the results needed to further parameterize the Twin Builder setup as part of a larger model, which can be optimized to meet necessary component requirements.

Ultimately this workflow will be used to calculate not one, but thousands of different designs to find a very specific concept which can then be benchmarked against a similar competitive product in the market for factors including performance, efficiency, compactness, and cost. It also enables ZF to deliver competitive, yet simple electric motor designs that are standardized across their portfolio, giving the company a decided advantage in the ability to bring convenient mechanical power to these applications.

Temperature contour plots and flow pathlines in ZF's inductive exciter unit for the Separately Excited Synchronous Motor (SESM)

Working Within the Ansys Ecosystem Yields Faster Results

ZF electric motor simulations are run either on local high-performance workstations, or on worldwide available ZF clusters. Simulations are distributed to the cluster via an application programming interface (API), which enables fast high-performance computation (HPC).

Achieving shorter development times, plus a higher degree of maturity on the product side as quickly as possible, are big reasons for ZF’s big push for the use of multiphysics simulation in all of their programs. But that’s not all — simulation also facilitates ZF’s “blank canvas” approach to development, enabling the R&D team to freely play in the white space to figure out an entirely new principle reflected in a new product around a serious application for their customers.

“To transmit electrical power to a rotor of a brushless electrical excited synchronous machine, we developed a rotating inductive transformer unit,” says Robin Michelberger, Simulation Engineer also in the Advanced Development Department at ZF responsible for electrical design. “We used the Ansys simulation ecosystem to simulate multiple physics and domains. These simulations were also used to quickly evaluate thousands of design variants. This helped us to ultimately build up a hardware prototype that outperforms today’s benchmark in terms of power density, and still archives an efficiency of more than 95% at system level.”

Our work with ZF is just one example of how our automotive customers are optimizing electric motors using simulation. Be sure to visit our webpage dedicated to advancing electric motor development for automotive.