The Road to Opportunity

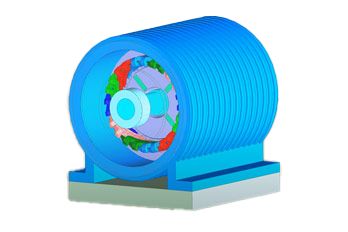

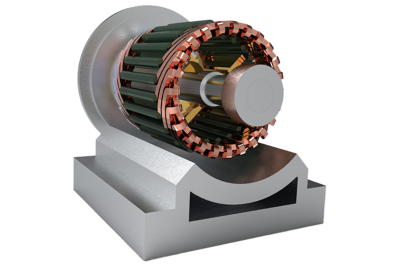

Between 2021 and 2023, electric vehicles (EVs) represent a $7 trillion market opportunity, and it’s only projected to increase. In a rapidly growing EV market, automakers are turning to advanced design, test, and manufacturing technologies. As part of this effort, engineers push the boundaries of electric machine design for greater efficiency and performance, ultimately driving traction motor adoption.

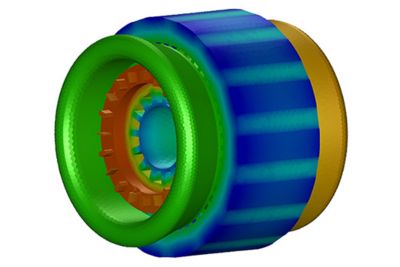

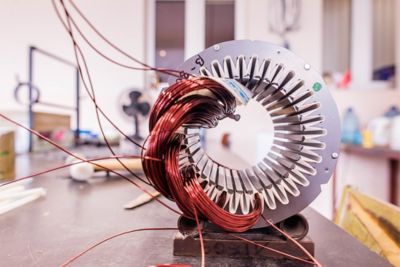

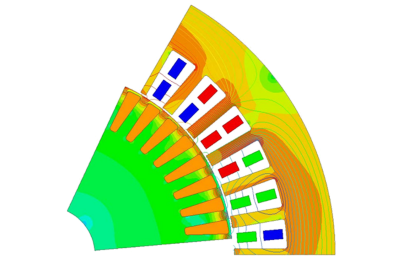

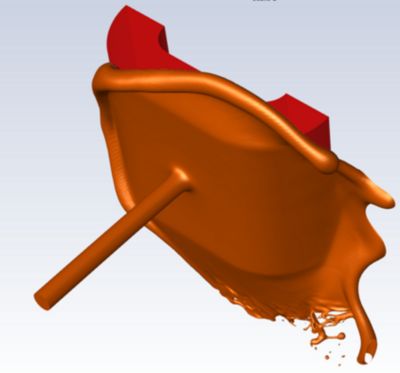

Motors are responsible for transforming stored energy into the energy needed for forward movement, with the powertrain and associated systems accountable for distributing, managing, and controlling the vehicle’s energy requirements and efficiency.

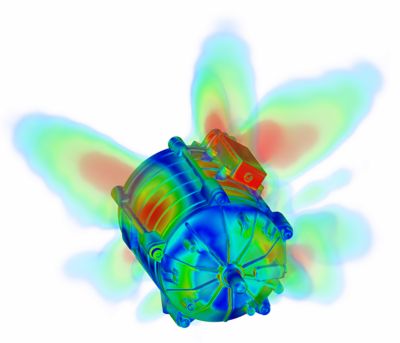

When considering the electric drivetrain, several design targets impact the function of the entire vehicle: