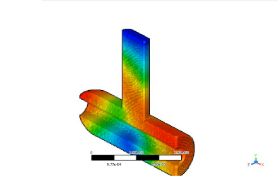

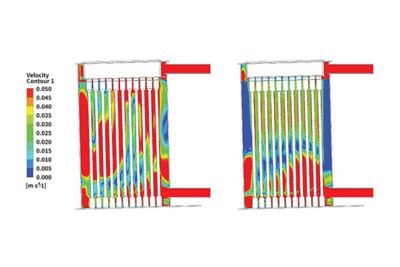

Shape Optimization

Heat exchanger shape selection can be optimized by leveraging parameters, adjoint methods and response surfaces.

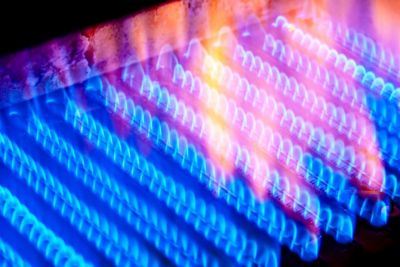

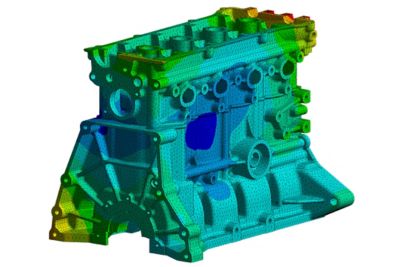

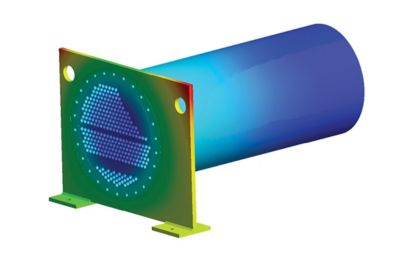

Conjugate Heat Transfer

Performing steady or transient conjugate heat transfer simulations determines heat exchanger performance and the impact of thermal stresses. Models can include fluid structure interaction, fatigue life prediction and multiphase boiling, condensation and evaporation.

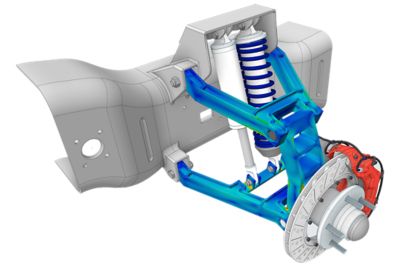

System Level Integration

Using reduced order models (ROMs), high-fidelity physics simulations integrate with overall system level models for process integration and design optimization (PIDO).