-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Savings Boil Over

Stefano Argenton, R&D Product Development, Ferroli, San Bonifacio, Italy

Gas condensing boilers rely on the successful thermal exchange between hot flue gas and water flowing within the tubes of a heat exchanger. Ferroli, a manufacturer of boilers and renewable energy products, used Ansys Fluent to respond to market requirements for a high-efficiency heat exchanger. The results enabled its engineers to create an optimized design for a robust, high-performance condensing heat generator.

Gas boilers are widely used to power domestic and commercial central heating systems. Unlike conventional boiler designs, condensing boiler technology can recover heat loss. Because condensing boilers are more energy efficient and environmentally friendly, some countries mandate their use in new installations.

Ferroli is an Italian manufacturer of heating appliances founded near Verona in 1955. The company has brought many appliances to the global marketplace, including a range of gas condensing boilers. With an innovative design, these boilers offer 100% thermal efficiency — a measure of the ability of the exchanger to transfer heat from the combustion process to the water or steam in the boiler.

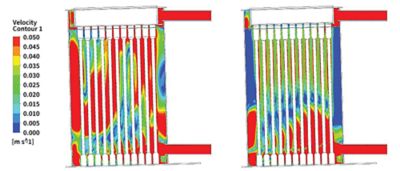

Velocity profile comparison between the new design (left) and the old design

After a benchmark analysis, marketing and the research and development director decided a new boiler was needed. One of the main goals was to improve efficiency and robustness. Engineers at Ferroli employed Ansys Fluent computational fluid dynamics (CFD) software to design it. The results of the simulation allowed the engineers to create a good design achieving the requirements of both efficiency and durability of the device.

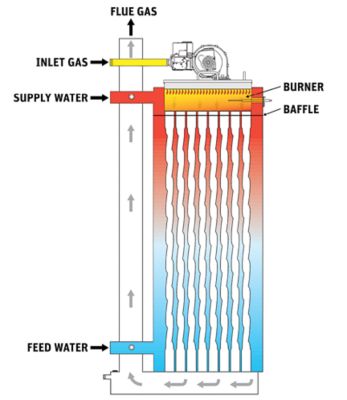

INSIDE THE BOILER

As a shell and tube heat exchanger, Ferroli’s condensing boiler model consists of a vertical tube arrangement inside a stainless steel shell. It has a power output of 320 kW and is used to heat the central heating system in commercial settings, such as hospitals and shopping malls.

The process starts in the combustion chamber where natural gas is ignited by the burner. Flow through the shell is countercurrent in that the hot flue gas flows in the opposite direction of the water flowing through the tubes.

A working diagram of a boiler shows how heat is exchanged.

The “feed” water, which is cool from having circulated around the heating system, enters through a pipe at the bottom of the boiler. As it flows up through the heat exchanger, it is reheated. The hot water then leaves through the “supply” pipe at the top of the boiler to continue circulating around the heating system.

As the flue gas is conducted down through the shell from the combustion chamber, its heat is also transferred to the cool feed water. As this flue gas cools, the water vapor contained within it gradually condenses. The condensate is discharged through a waste water pipe. As a result, condensing technology recovers the heat that otherwise would have been lost to the environment via the flue.

Components within the heat exchanger that are vital to a successful thermal transfer between the two fluids are the tubesheet and the baffle. A tubesheet is a plate that is secured at both ends of the heat exchanger. It is welded to the shell and includes holes through which the tubes that contain the flowing water are inserted. Baffles located within the shell are designed to support the tubes and direct flue gas across the tube bundle, allowing for efficient heat transfer.

Ferroli immediately saved €75,000 in equipment and labor costs with Ansys Fluent, but the gains of making it to market faster are immeasurable.

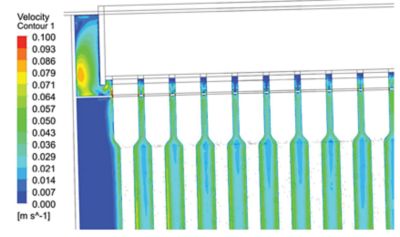

Velocity profile of the new boiler with the new baffle’s shape

Velocity profile of the previous boiler baffle design

THE KEY TO DEVICE IMPROVEMENT

When Ferroli’s engineers started the design study of the new boiler, the first concern was the possibility of limescale formation inside the heat exchanger. Limescale is a result of hard water. Depending on where you live in the world, water is characterized as either hard or soft. Hard water contains a significant quantity of dissolved minerals, such as calcium and magnesium, which can settle in the pipework forming a hard, chalky deposit. The accumulation of limescale in the heat exchanger caused water to become trapped and overheat, which raised the temperature of the steel tubesheet.

Ferroli’s engineers employed Ansys Fluent software to analyze the internal water distribution within the heat exchanger. Their goal was to improve the heat exchange coefficient under the tubesheet, leading to higher water flow velocity.

To predict the fluid flow behavior of water as it enters the heat exchanger and its distribution through the tubes, Fluent was used to solve the various equations for flow velocity, flow path and heat transfer. In particular, the engineers used the K-epsilon turbulence model feature to predict turbulent flows.

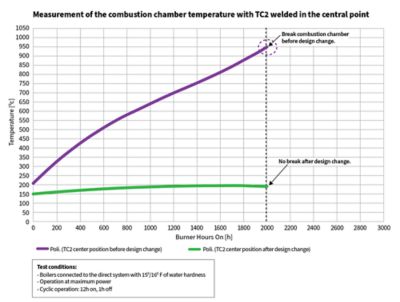

A simulation of the temperature of the upper plate before (left) and after the redesign

STEPS TAKEN TO SOLVE THE PROBLEM

Engineers began by analyzing the previous boiler design as a starting point for the design study of the new one. In addition to the meshed virtual model created with Ansys meshing, a physical boiler model was being tested in Ferroli’s test lab. A comparison was made between the lab test results and the results of the simulation. The simulation model was updated with boundary conditions of heat transfer and heat loss that were discovered as a result of the lab tests.

With the results of the simulation, together with the engineering expertise garnered over many years of designing boilers, the engineering team decided to update the shape of the baffle. An analysis of this new model revealed a substantial improvement in the flow and heat exchanging behavior of the boiler.

A further change was made to the design to decrease the space between the tubesheet and baffle and increase the diameter of the baffle’s holes in some areas while decreasing them in others. This change allowed for the best flow distribution and increased the velocity of the water flowing between the tubesheet and baffle. Limescale does not form above a particular water velocity value. Furthermore, higher water velocity under the upper plate lowers the steel temperature, so the working life of this boiler increases.

It took just three simulations to find the right design for the boiler. A prototype of this design was produced and installed in Ferroli’s test lab in August 2018. Following one year of physical testing, the prototype confirmed the results of the Ansys analysis.

Graph of the failure during cycle lab test under extreme working conditions. This condition is rarely encountered during real field operation.

SAVING BOTH TIME AND MONEY

Previously, four physical prototypes had been built to find the best solution for increasing the efficiency and durability of the boiler. However, with the use of Fluent CFD software, only one physical prototype was needed for the new boiler model. Considering the time it takes to build and then test four prototypes, Ferroli estimates that it has saved at least one year of product design and development time by using simulation. The associated cost in lost opportunities and sales during that year is immeasurable.

In addition to saving valuable time, simulation also yielded substantial equipment and labor savings for the company. One physical prototype costs €20,000 (about $22,000) to build, so Ferroli immediately saved €60,000 by using simulation on boiler projects. At least two operators would then take five days to prepare the test and analyze the physical test data, which is estimated to cost around €15,000 more.

Given the impressive time and cost savings of the boiler project, Fluent CFD software is now being used in more projects at Ferroli. For instance, it’s being employed in the simulation of new designs, such as heat pumps and biomass combustion products. The use of simulation is also being expanded to solve additional issues and enhance the performance of existing products.

시작하기

엔지니어링 과제에 직면하고 있다면우리 팀이 도와드리겠습니다. 풍부한 경험과 혁신에 대한 헌신을 가지고 있는 우리에게 연락해 주십시오. 협력을 통해 엔지니어링 문제를 성장과 성공의 기회로 바꾸십시오. 지금 문의하기