-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

Ansys博客

November 15, 2023

仿真如何助力汽车制造商实时了解行业趋势

我们熟知的一切移动出行都在发生日新月异的变化。电气化和自动驾驶汽车以及智能网联和人工智能(AI)正在颠覆整个行业。所有这一创新的核心都是仿真。那么,下一步会是什么呢?继续阅读,深入了解我们的发展方向。

仿真为实现全电动未来注入强大动力

尽管市场预测情况很乐观,但消费者对电动汽车(EV)的接受度仍然是一个挑战。消费者对购买电动汽车越来越犹豫不决,价格和充电仍然是两大障碍,因此,原始设备制造商(OEM)正在后延电动汽车的推进目标。即使消费者有能力购买,但如果没有落实足够的基础设施来帮助他们为电池充电,电动汽车又能行驶多远呢?

在提高效率的竞争中,OEM厂商和顶级汽车供应商正在寻求数字工程和数字创新,突破他们的设计界限并加速发展其电气化战略。然而,电动汽车技术的不同之处就在于其变革途径。

要增加燃气动力汽车的续航里程,只需增大燃油箱尺寸即可。但增加电动汽车的续航里程显然要复杂得多。如果仅是添加一两个电池模块,可能会对车辆设计产生不良影响,因为必须通过调整来考虑额外的重量、电机尺寸和更多的电子设备散热。

“那(优化)对致力于该领域的工程师意味着什么呢?”,Ansys技术客户经理、电气化动力总成专家Zed Tang博士提出。意味着再也无法通过足够的原型或测试来确定这额外的0.1%效率如何实现。工程师必须深入挖掘,但如何做到这一点呢?可以使用仿真,因为借助仿真,我们可以了解所有这些情况。通过在多处进行调整,并增加自动化和优化,就可以以虚拟且直观的方式查看结果,从而更好地了解如何获得额外的0.1%效率。”

德国采埃孚通过仿真助力提高电机设计效率

电机在电气化过程中发挥着重要作用,因为它们使用电磁力将电池的电力转换为机械动力,以驱动车辆。不过,在充电过程中收集的能量,并不能全部在转换过程中被收集和使用。对于OEM厂商而言,任何电机设计的目标都是实现最高能效,以确保电机可将电池的大部分能量用于增加车辆的续航里程。

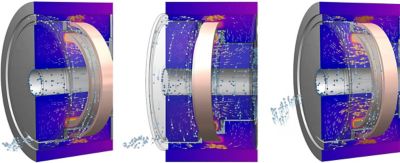

采埃孚(ZF)分励磁同步电机(SESM)感应励磁装置的流体、热及电磁仿真

Ansys仿真可帮助全球科技公司采埃孚低成本地开发用于量产的电机和相关产品,并提供最能满足OEM厂商需求所需的最简单功能。通过仿真,采埃孚可在产品端和仿真端实现研发标准化,以提高与电机性能相关的效率。

仿真优化车辆,带来自动驾驶体验

绝大多数消费者表示,他们对自动驾驶技术持怀疑态度。但尽管这种犹豫的阴霾没有消散,但人们通过高级驾驶辅助系统(ADAS)获得更直接支持的愿望持续走高。

其中一些大众化系统包括:

- 碰撞警报与制动:包括前向碰撞警报和自动紧急刹车。

- 自适应巡航控制:包括可以在高速公路行驶速度行驶时调节速度,以及跟随低速交通拥堵时的系统。

- 车道辅助系统:包括车道偏离预警和车道保持辅助系统,其功能强弱因制造商而异。

- 盲区警示:现代版本通常包括后方交叉交通警报,以及最近的倒车自动紧急刹车。

- 驾驶员注意力监控器:包括监控方向盘输入的被动系统,以及使用摄像头监控驾驶员面部表情的主动系统。

在幕后,汽车工程师将一如既往地推动自动驾驶汽车技术发展,改进现有ADAS解决方案,并推进自动驾驶技术的进一步未来发展。这项工程非常巨大,因为只通过仿真技术根本无法验证自动驾驶汽车性能。相反,OEM厂商必须依靠行业特定场景来证明其系统的安全性。

Ansys自动驾驶汽车业务拓展兼领域专家Gilles Gallee表示:“采用自动驾驶技术基本上能够减少对驾驶产生不利影响的所有人因。因此,为了消除这些风险因素,我们必须能够自信地指出,自动驾驶比人类驾驶员更安全,才能完全接受自动驾驶汽车。

与自动驾驶仿真工具链一起使用时,Ansys安全分析软件可将大规模仿真的优势与优化安全验证所需的统计数据和基于场景的分析相结合。此外,其还支持虚拟传感器仿真,以在现实场景中进行感知测试和传感器行为验证,从而可实现更高效的可靠性分析。

EasyMile采用Ansys软件实现更安全的自动驾驶汽车操作

自动驾驶技术所需的实时数据处理,高度依赖激光雷达、雷达、摄像头、物联网传感器、GPS和导航软件组成的复杂系统提供的输入,所有这一切协同工作,从而实现了以360度的全方位视角呈现车辆周围的环境。想要证明这一级别的安全性是非常困难的,需要明确的方法和工具来管理这些非经典系统的复杂架构。

使用Ansys软件,EasyMile确定了统一的解决方案,包含了分析其极为复杂的AV系统架构所需的所有工具。在Ansys的帮助下,EasyMile制定了明确的安全分析指南,以及为客户及各类政府监管机构成功展示其AV解决方案安全性所需的独特模板和辅助文档。

通过仿真帮助自动驾驶汽车建立连接、学会处理新情况

在实现完全自动驾驶之前,我们还有很长的路要走。在自动驾驶生态系统中,自动驾驶汽车和其它元素之间仍需要进行大量会话/信息交流,才能确保安全,让人们放心交出方向盘控制权。这看似简单,实则是一项巨大的计算任务,涉及大量需要近实时响应的车载应用。

在从安全验证到真实环境传感器及天线性能验证的每个环节,所有这些活动都将在仿真支持的高速网络中通过AI及阶次互联协调。这就是诸如此类的数据驱动型洞察,与机器学习(ML)相结合,加速了自动驾驶技术的发展。

Ansys高级研发总监Jay Pathak表示:“最终,这是通过AI/ML驱动型决策系统实现的,该决策系统与基于规则的自动驾驶汽车系统密切配合,将真实驾驶环境中复杂的安全操作放在安全考虑的首位。在汽车AI/ML中,其中一项重要挑战是:数据不能准确覆盖整个空间时,因此,探索这些规则就会成为一个棘手的问题。”

要获得必要的数据,就必须从大数据转向有用的数据,并通过仿真增强的非监督式AI学习方法,在数据集中创建具有挑战性的动态情况,否则在真实情况下很难找到这些动态情况。通过从海量驾驶仿真中掌握所有数据,AI可通过软件应用更好地告知自动驾驶汽车如何在给定驾驶情况下做出反应。

安森美(onsemi)依靠仿真技术支持车辆感知能力

自动驾驶汽车软件协议栈由多层组件组成,负责自动驾驶所需的感知、互联、处理、分析和决策。车辆的感知协议栈的行为和人类驾驶员非常相似,其会先“环顾四周”,从车辆传感器收集数据,然后对其进行处理,以了解目前的驾驶环境并对其做出响应。

Hyperlux(右)系列保持闪烁能力的车灯。未观察到上一代(左)传感器中出现的伪影。

安森美是电源和传感器技术的领导者,始终致力于推动创新发展,开发智能技术,以应对复杂的客户挑战,其中包括有关车辆感知的挑战。通过与Ansys合作,安森美团队创建了一个传感器模型和一个虚拟孪生模型,然后通过仿真整合了各种驾驶场景,从而将传感器模型转换成了更广泛的系统级仿真,其可分析、评估并开发针对客户需求量身定制的新一代传感器应用。

当然,还有更多其它内容

我们简要介绍了推动汽车发展的三大趋势。如欲了解更多洞察信息,请务必查看我们的行业思想领袖对电气化、自动驾驶以及互联和AI/ML的见解。

我们于1月前往拉斯维加斯,参加2024国际消费类电子产品博览会(CES 2024)。无论您是现有客户还是潜在客户,我们都期待在那里与您会面,助您实现未来移动出行领域的重大创新构想。欢迎在国际消费类电子产品博览会上莅临6500号展位,了解仿真如何推动汽车创新发展。