Simulation continues to transform workflows around the world, regardless of industry. Product development teams are constantly challenged to produce better designs at a faster pace. By incorporating simulation earlier into design and development, these teams accelerate production and inform design with critical insights that improve efficiency, accuracy, and product quality. But as impactful as this “shift to the left” is — i.e., using simulation earlier to inform design rather than as a late-stage verification or post-analysis tool — artificial intelligence (AI) technologies present another opportunity to drastically shift production and simulation workflows.

By combining the power of AI and multiphysics simulation, the Ansys SimAI cloud-based platform enables organizations to reach even greater levels of innovation at a rapid pace. With the SimAI physics-agnostic and cloud-native platform, you can train an AI model using previously generated Ansys or non-Ansys data and assess the performance of a new design within minutes. The software-as-a-service (SaaS) application combines the predictive accuracy of Ansys simulation with the speed of generative AI via the cloud — a combination that boosts model performance by 10-100X across all design phases for computation-heavy projects.

So, how do AI and machine learning (ML) methodologies integrate with and extend upon numerical simulations and solvers? Let’s explore the inner workings of the SimAI platform to learn how this technology both expands and enhances traditional simulation without compromising accuracy for speed.

Inform Machine Learning with Numerical Simulation

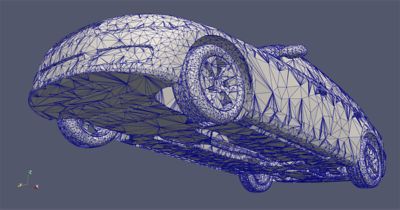

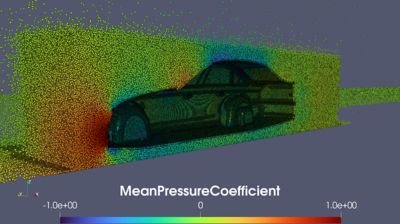

To appreciate the technology behind the SimAI platform, you must first understand the nature of numerical simulations and their complexities and purpose. Numerical simulations model the behavior of physical systems in various engineering domains without needing to conduct lab experiments. This enables engineers to calculate and iterate system-specific quantities more easily and efficiently. For example, to assess automotive aerodynamics, engineers often rely on computational fluid dynamics (CFD) simulations to analyze the flow field around a car.

To assess automotive aerodynamics, engineers often incorporate computational fluid dynamics (CFD) simulation to analyze the flow field around a car.

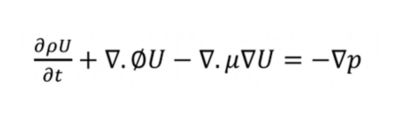

Governing equations play a crucial role in the analysis of physical systems because they enable models that can be used to analyze and predict behaviors that are otherwise unobservable. By employing mathematical approximations, numerical simulations solve these governing equations through computer algorithms. Some of the most well-known governing equations in engineering are the Navier–Stokes equations, which are used to express the motion and flow of incompressible fluids. In the case of automotive aerodynamics, Navier–Stokes equations help describe the relationship between the velocity and pressure of moving fluid around a car.

The Navier–Stokes equations, shown here in their incompressible forms, describe the relationship between velocity and pressure of the moving fluid.

When employing ML techniques, the goal is to enable an algorithm to learn a task or general rule, given a set of examples. There are several ways to do this when integrating ML with numerical simulation.

Here are two categories of such methods:

- Physics-aware: The most straightforward approach is to replace the bottleneck in standard solvers with ML techniques that can output predictions faster, e.g., to accelerate the inversion of a large linear system of equations. However, most of these methods remove the solver involved in the computation while keeping information about governing equations, e.g., by injecting penalization terms implied by the equations into the loss function, i.e., the amount of error in your training data. In other words, physics-aware methods focus on a particular physical task and get the job done, but they might sacrifice some accuracy.

- Physics-agnostic: The other approach is for the ML algorithm to learn a latent representation of the physics directly from the solutions of numerical solvers. These methods are agnostic to the underlying equations and solvers. For example, by using examples from previous computations, ML algorithms can learn a data-driven representation of the Navier–Stokes function and use a new geometry and freestream condition as inputs like the speed of a car to deliver its flow field as the output. In this way, physics-agnostic methods offer both speed and predictive accuracy.

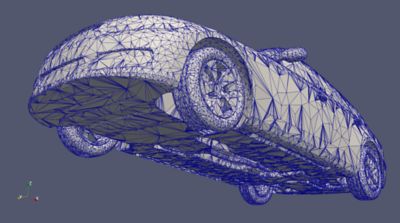

The SimAI platform takes a physics-agnostic approach, accelerating your simulation workflow without compromising its predictive accuracy. Instead of relying on geometric parameters to define a design, SimAI software uses the shape of a design itself as the input. This facilitates broader design exploration even if the shape’s structure is inconsistent across the training data.

Essentially, the SimAI platform is engaged in three simple steps: upload data, train AI model, and predict. As mentioned, customers can train the AI model using previously generated Ansys or non-Ansys data.

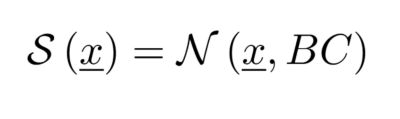

By using examples from previous computations, the physics-agnostic machine learning (ML) techniques used in Ansys SimAI can learn a data-driven representation of the underlying governing equations of your system, e.g., the Navier–Stokes functions.

Ansys SimAI: Discover What’s Under the Hood

The generic architecture of the SimAI platform is based on a fusion of different techniques that combine multiple deep learning neural networks. This type of architecture makes it possible to capture all the important scales of physics. The architecture is composed of a significant number of nonlinear layers, including multiple parameters and complex interactions between variables.

SimAI’s architecture is composed of a significant number of nonlinear layers, which include multiple parameters and complex interactions between variables.

Instead of explicitly storing data points like pixel values in an image, the SimAI platfrom uses an implicit neural representation to learn a continuous function that can generate these data points. This means that SimAI software can take a set of points obtained from previous computations and generalize well to new geometries and freestream conditions.

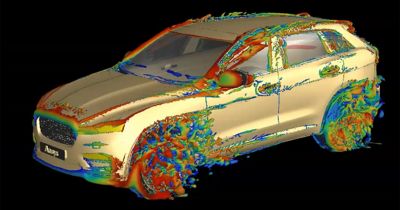

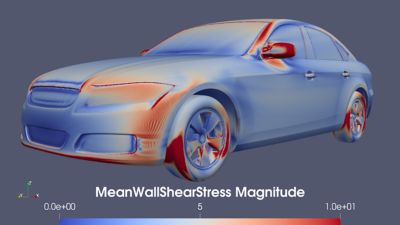

Keeping with the example of automotive aerodynamic assessment, this capability enables a continuous representation of the surface and volume fields, e.g., pressure and velocity. This makes it possible to request a prediction at a desired resolution. Additionally, global coefficients can be derived from the predicted fields as post-processing.

For automotive aerodynamic assessments, the SimAI platform enables a continuous representation of the surface and volume fields like pressure and velocity. In addition, global coefficients can be derived from the predicted fields as post-processing.

In fact, one of the SimAI platfrom's strongest assets is its use of regularization techniques to prevent overfitting and improve generalization for new geometries. What does this mean? Basically, overfitting is when an AI model’s predictions are too narrowly focused on its training data and included geometry, lacking any generalization or scope to learn or generalize new geometries. Regularization techniques are designed to reduce overfitting. SimAI uses regularization techniques, including local methods that are embedded directly in the structure of the model and lead to a more stable and expressive model. It’s the reason SimAI software can work with new geometries so quickly and easily.

Similarly, the SimAI platform uses an adequate representation of 3D shapes to describe arbitrary or irregular meshes with complex geometrical variations that do not follow a specific distribution, e.g., unparameterized geometries. To help quantify the uncertainty in the prediction, SimAI software uses a unique confidence score to calculate the distance from the nearest known geometry in a very high-dimensional space.

Regardless of a new geometry’s mesh resolution, the SimAI platform will return the same confidence score because it adopts an underlying representation of the shape, therefore producing the same output.

Expand Simulation with the Ansys SimAI Platform Today

While it’s good to know the basics of SimAI software's technology behind the scenes, the best part about the platform is that you don’t need to know any of this to use it. It is intuitive and designed for users without coding experience, AI/ML familiarity, or deep learning expertise.

By catering to a broad engineering audience, the SimAI platfrom empowers product engineers, designers, and nonexperts across all industries and engineering domains to easily leverage previous simulation and measurement data to assess the performance of new designs within minutes instead of hours.

To learn more, register for the webinar “Introducing Ansys SimAI: Cloud-Native Generative AI for Simulation.”

The Advantage Blog

The Ansys blog, featuring contributions from Ansys and outside experts, keeps you in the know with the latest industry information, including engineering articles and simulation news, thought leadership and trends, product development advances, tips to better use Ansys solutions, and customer stories.