-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Digital Twin Prevents Drain on Battery Pack Simulation Time

By Azita Soleymani,

Director, Electronic Cooling Solutions, Santa Clara, U.S.A.

The global shift to electric vehicles (EVs) is coming, and unless alternative technology emerges, it will be fueled by high-capacity lithium-ion (Li-ion) batteries.

Making the hundreds of millions of Li-ion batteries the world will eventually need for electric mobility is a massive undertaking full of technical challenges. Concerns about battery pack size, weight, cost and sustainability have to be resolved before there can be a mass rollout of “green” cars. So do issues about battery life span and safety, which can be affected by thermal conditions. Among other benefits, regulating cell and battery pack temperature within a given range can increase the number of cycles a battery can achieve, making performance more dependable. More important, an effective thermal management solution can reduce the possibility of catastrophic battery failure.

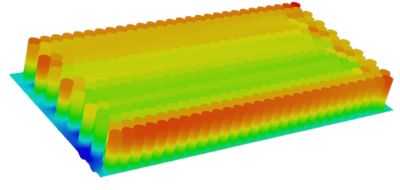

A temperature profile of a battery module

Electronic Cooling Solutions, Inc., provides thermal management expertise to the electronics industry, rapidly identifying and resolving thermal questions using analytic and optimization tools, including Ansys simulation software.

Recently, the company used Ansys Fluent and Ansys Twin Builder to investigate design optimization of a battery pack thermal system. Simulation enabled Electronic Cooling Solutions to:

- Develop and validate the best operating setup for user comfort and safety

- Validate the design for aggressive scenarios such as fast driving, cold start and fast charging

- Conduct troubleshooting

- Predict performance decay with age

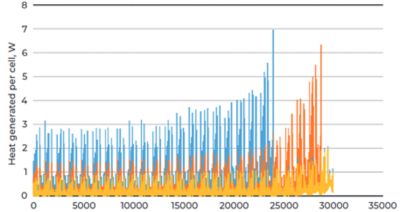

This graph shows the typical heat-generation data from an equivalent circuit model of Li-ion cells. Color indicates the impact of operating temperature on the rate of heat generation.

Monitoring Battery Packs for Preventive Maintenance

Operating an EV requires an enormous amount of energy, which is why the battery is such an important — and expensive — component. It is not unusual for the battery to represent as much as 50% of the total cost of the EV.

There are two main types of Li-ion battery cells: cylindrical and prismatic. Cylindrical cells are small, typically measuring 2 cm in diameter and 7 cm in height, and there can easily be thousands of them in an average battery pack. Typically, the cells are organized into clusters called modules. Multiple modules form a pack.

Unlike most electronic integrated circuits and microchips in electronic devices, the optimal temperature range for Li-ion battery packs is quite narrow and varies depending upon cell supplier, charge and discharge mode, and other factors. To ensure performance — and to avoid irreversible damage — the average temperature of the cells and the temperature difference among them should be within a target range.

Battery packs are designed with separators to keep electrodes from touching one another and generating heat. Unfortunately, separators can fail for a number of reasons: A side-impact collision can tear them, an electrical shock can pierce or puncture them, and extreme temperatures, either ambient or related to the car’s operation, can cause the separator to collapse. If any of these events occur, it can lead to thermal runaway. As a result, the battery begins smoking, catches on fire or even explodes. As for the car, it can be a total loss.

To prevent these problems, Electronic Cooling Solutions characterized a robust, reliable and cost-efficient battery pack temperature monitoring system. Because a Li-ion battery pack is a highly convoluted multiphysics system, the company had to take into account a variety of key factors, such as analyzing in transient fashion:

- Heat generation as a function of the design of the battery pack’s busbars, which are used for local high current power distribution, and the speed of electrochemical reactions, which is dependent upon temperature, state of charge (SoC), electric current and electrochemistry properties of the cell

- Heat removal rate as a function of coolant flow rate, design of cooling system and change of coolant physical properties with temperature

- Three-dimensional spread of dissipated heat

A design of experiment (DOE) approach had to incorporate a range of conditions to ensure that all thermal requirements were met: fast charging, cold start, charging at low temperature, discharging when the charge was low and different drive cycles.

Using conventional computational fluid dynamics (CFD) to validate design is not practical because of the large number of cases that have to be considered. Although it is possible to perform and link 1D and 3D simulations, each method has limitations that could cause design problems. For example, although 1D simulation is fast and allows for multiphysics analysis, it doesn’t include 3D visualization of the problem. On the other hand, 3D transient battery pack simulation can be computationally expensive, considering the large number of cases.

To overcome those issues, Electronic Cooling Solutions developed a digital twin that provided the accuracy and reliability of 3D battery pack simulations and the computational speed of 1D.

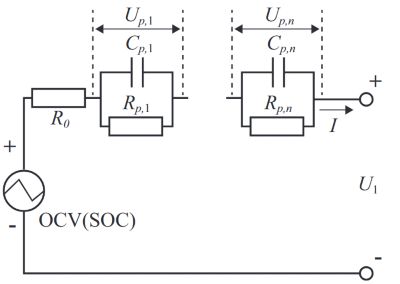

The 2RC model representing the Li-ion battery cells’ temporal thermal and electrical performance

Digital Twin Enables Real-time Analyses

The company used Twin Builder to capture live sensor data and develop a digital twin model of Li-ion battery packs that captured real-time behavior in a real-time environment. This allowed engineers to conduct in-depth root cause analyses on various inputs and operating conditions, including initial SoC, temperature, coolant flow rate, and different charge and discharge profiles.

To generate the digital twin, engineers began by characterizing battery cell performance. Considering the highly convoluted multiphysics nature of Li-ion battery cells, the thermal load of each battery cell at one instant in time depends on the cell type (manufacturing parameters), SoC, cell temperature, charge/discharge mode, magnitude of electric current extracted from cells and aging. Typically, each cell is represented by a 2RC model (with one resistance and voltage source in series). Engineers also conducted hybrid pulse power characterization (HPPC) tests to characterize and estimate the cell parameters.

Next, they used Twin Builder to create an equivalent circuit model (ECM) of a battery cell that accounted for all electrochemistry behavior, and then applied the model to real-time heat generation. The ECM approach is based on the battery cell’s impedance response — that is, its resistance to alternating current — under different external conditions.

Engineers then performed transient 3D simulation using Fluent to generate response curves at the battery pack level. They fed the response curves into the reduced order model (ROM) application of Fluent to create the ROM of the battery pack. Linking the ROM and ECM of the battery cell in Twin Builder produced a digital twin model of the battery pack. It has the accuracy of the conventional 3D analysis and the speed of 1D system-level analysis.

Electronic Cooling Solutions validated the developed model by comparing results against available test data. They then used the model to evaluate design feasibility under various operations and to optimize and troubleshoot the design.

Thermal Management Critical for Mainstream Electric Vehicles

Thermal management of Li-ion batteries is a daunting task that can be computationally expensive and time-consuming. But with more than half of the new cars on the road expected to be all-electric by 2040,1 vehicle reliability and driver safety depend on it.

By relying on Ansys results-driven software, Electronic Cooling Solutions was able to consider the critical design elements required for an effective thermal monitoring system and significantly reduce the calculation time from weeks to hours compared to other approaches. This resulted in significant time-to-market reduction. Electronic Cooling Solutions provided their client with recommendations for a high-performance product designed to help bring EVs into the mainstream — and bring the future closer to reality.

Source

- “By 2040, more than half of new cars will be electric,” Bloomberg New Energy Finance via CNN.com, Sept. 6, 2019

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。