-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Charge Up ISO Certification via medini analyze

By Ole Tidemann, Functional Safety and ISO Certification 26262 Manager, LiTHIUM BALANCE A/S Smørum, Denmark

LiTHIUM BALANCE, a startup company based in Denmark, has used Ansys medini analyze to accelerate and streamline the ISO 26262 certification process for its battery management system (BMS) solutions. Because ISO certification is critical to supplying BMS products to global electric vehicle manufacturers, medini analyze represents a significant competitive advantage in an increasingly crowded marketplace.

LiTHIUM BALANCE A/S was founded in 2006 with a straightforward goal: to provide the first genuinely effective, reliable battery management system (BMS) for the lithium ion batteries that power electric and hybrid automobiles.

Though this goal is straightforward, it is not simple. The BMS is a sophisticated control center that monitors and manages the charging, energy storage and daily operation of automotive batteries. In the event of any disruption or failure — such as overheating — the BMS must act intelligently to shut down the battery, while ensuring that the safe operation of the vehicle is not affected.

Obviously, the BMS is crucial to the functional safety of the entire vehicle, which means that solutions from LiTHIUM BALANCE must meet the stringent demands of ISO 26262 to be sold broadly into the global automotive marketplace. While LiTHIUM BALANCE has delivered more than 800 BMS solutions to customers and won awards for innovation, its ISO 26262 certification will open much larger sales opportunities for the startup business.

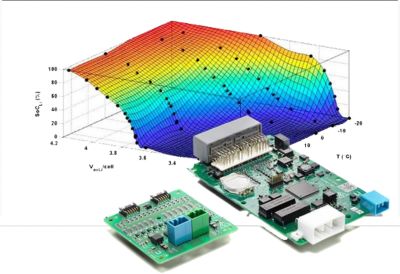

The LiTHIUM BALANCE BMS, including an indication of how the battery capacity (state of charge) is automatically calibrated.

POWERING THROUGH THE COMPLEXITIES OF CERTIFICATION

As any supplier to the global automotive industry knows, achieving ISO certification is a complex process that can take years. It requires extensive verification and documentation. With the pressure placed on automakers to introduce electric and hybrid vehicles quickly ― to meet both government standards and consumer demand for greener alternatives ― the LiTHIUM BALANCE engineering team needed to minimize the time involved in gaining ISO certification. The company’s success depends not only on developing safe, verified BMS solutions, but in launching them as quickly as possible.

In 2017, the functional safety team at LiTHIUM BALANCE began using Ansys medini analyze to accelerate and streamline the process of ISO certification. An easy-to-use, model-based tool, medini analyze helps LiTHIUM BALANCE identify battery failure rates and mechanisms across thousands of operating scenarios, then document how the BMS will respond to each of these events.

Deep analytic capabilities offered by medini analyze verify that there will be an appropriate response to every foreseeable battery failure. The result? A clear, visual demonstration that BMS solutions from LiTHIUM BALANCE are verified for functional safety under virtually every operating scenario. ISO reviewers have already given LiTHIUM BALANCE positive feedback about the company’s use of medini analyze to submit the required proof of functional safety and obtain approvals.

The rigor of the analysis and documentation process in medini analyze has proven invaluable not just in achieving ISO certification, but in making sales to customers who need verification of a specific BMS solution’s safe performance. Medini analyze offers clear visibility into the functional safety analysis process at LiTHIUM BALANCE, and its technical breadth and depth have been a key selling point with customers to date.

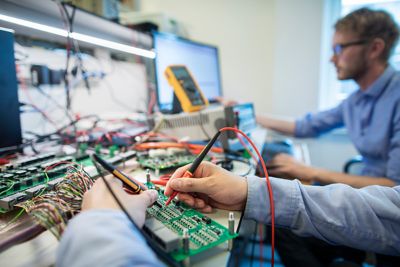

BMS system testing at LiTHIUM BALANCE

SAVING ENERGY, TIME AND COSTS

Prior to using medini analyze, the functional safety team at LiTHIUM BALANCE was adapting Excel spreadsheets to the task, a common practice in the worldwide auto industry. This process was not only time-consuming, but it also involved significant manual labor and was prone to human error.

Because medini analyze is an automated tool designed specifically for documentation, it has resulted in greater accuracy while enabling LiTHIUM BALANCE to identify any functional safety shortfalls at a very early stage of BMS design.

Any issues flagged by medini analyze can be quickly addressed by the engineering team, then the modeling can be repeated ― resulting in a closed loop of continually enhanced functional safety. For instance, if the failure rate of a single BMS component is improved, it is reflected automatically and universally by medini analyze. Any design updates that impact functional safety are made and reflected easily. This level of flexibility and agility is essential in supporting LiTHIUM BALANCE’s commitment to product innovation.

In addition, because many of LiTHIUM BALANCE’s BMS designs are customer-specific, yet built on a common product platform, medini analyze offers a flexible, accessible repository of functional safety data that can be customized for each new BMS product iteration.

Functional safety team members have been able to easily master this intuitive solution, resulting in rapid adoption of medini analyze at LiTHIUM BALANCE. The company has been able to minimize the human resources devoted to the complex process of ISO certification, allowing team members to devote their time to more strategic engineering work.

Perhaps the most significant benefit in today’s crowded automotive market is the speed at which LiTHIUM BALANCE has been able to accomplish the complicated modeling, verification and documentation work involved in gaining ISO certification.

Not only does the company need to build and test fewer physical prototypes, but medini analyze efficiently manages the challenging administrative requirements involved in ISO certification. As just one example, there are approximately 80 functional safety documents required for automotive industry certification. For the 20 most mission-critical documents, involving deep analysis, medini analyze has cut the delivery time by 50% ― a tremendous advantage.

The latest ISO 26262-certified BMS generation from LiTHIUM BALANCE

DRIVING TOWARD A CRUCIAL MILESTONE

LiTHIUM BALANCE earned its ISO certification in July, marking a strategically important milestone that places the company on equal footing with much larger, more established businesses that are supplying BMS products to the global marketplace. In addition, by establishing the organization’s functional safety leadership, ISO certification positions LiTHIUM BALANCE to develop BMS solutions for new markets and applications, including drones, robots and industrial equipment.

Just as BMS solutions from LiTHIUM BALANCE are known for their innovative technology and high performance, the company’s product development team routinely leverages the most advanced, highest-performing engineering technologies, including simulation via Ansys solutions. Because medini analyze manages and automates the process of compliance, industry certification is engineered into the company’s BMS solutions from the earliest stages of design — supporting LiTHIUM BALANCE’s leadership in the area of functional safety.

Assembly of battery sub-modules at LiTHIUM BALANCE

In the global automotive industry, there is no measure more important than safety. Backed by the capabilities of medini analyze, LiTHIUM BALANCE can offer both customers and ISO certification managers numerical, quantitative proof that its BMS solutions will perform reliably and safely under a range of operating parameters. This advantage is proving priceless as LiTHIUM BALANCE works to gain a leadership position in supplying cutting-edge battery management systems to the world’s automakers.

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。