Overview

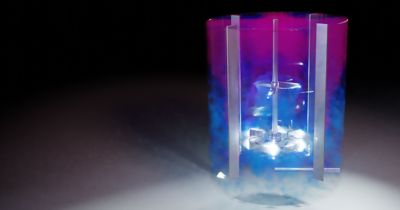

Bioreactors constitute the essential equipment for manufacturing the large molecules that make the biopharmaceutical industry so successful. Bioreactors contain a large number of living entities capable of producing the target drug under well-defined conditions of temperature, pH level, oxygen and nutrient supply, waste and unwanted gas evacuation. A complex balance between these conditions is necessary to ensure optimal cell productivity. If designing a good bioreactor is a complicated task, it's almost impossible to guarantee that the equipment will operate in optimal conditions throughout its life cycle despite the numerous internal and external variations in its operating conditions.

Creating and validating a reliable computer model of the equipment regularly interacting with the physical twin and capable of almost instantly predicting the likely evolution of the bioreactor so that the necessary actions guarantee maximum efficiency and productivity.

Such a digital twin of a bioreactor permanently connected to its physical twin, capable of linking the macroscopic flow model to cellular exchanges of gases and nutrients, is a reality gradually adopted in the biopharmaceutical industry. This webinar will show you how such a bioreactor can be built and validated to improve the design of your equipment and deploy it to maintain an optimal level of productivity.

What You Will Learn

- What is a bioreactor digital twin

- How to build these powerful computer models

- How could a bioreactor digital twin improve the design of the real equipment?

- How can these digital twins ensure high productivity despite adverse events?

Who Should Attend

Anyone in the pharma and biopharma industry directly or remotely involved with the upstream process of manufacturing medicine. This includes engineer, manager, director, VP and even C-Level related to process, production, safety, regulatory activities.

Speaker