Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

“Using Ansys Icepak software for our automotive interior lighting project transformed our approach to thermal management. The accurate simulations saved us time and allowed us to optimize material choices without the need for costly prototypes. Ansys has been a vital partner in our development process.”

— Antoni Vilatimó, Laboratory Engineer, Elausa

In the automotive industry, effective thermal management of electronic components is crucial, especially in space-constrained environments like interior ambient lighting. This project involved a new type of light-emitting diode (LED) with integrated circuits (ICs), needing a thorough understanding of thermal behavior to ensure reliability.

Challenges

The primary challenge was managing the power output of the LED printed circuit board (PCB) in high ambient temperature and within a limited space surrounded by plastic materials, which restricted airflow. The team required a simulation tool that could accurately model thermal performance and integrate seamlessly with existing electronic computer-aided design (ECAD) systems. Ansys Icepak® electronics cooling simulation software was chosen for its usability, precision, speed, and excellent technical support.

Engineering Solutions

To address the thermal management challenge, the team utilized Icepak software to perform comprehensive simulations of the PCB. Key features that facilitated their success included:

- Advanced computational fluid dynamics (CFD): enabled detailed conjugate heat transfer analysis to predict airflow and temperature distribution

- ODB++ import functionality: streamlined the integration of PCB layout designs for precise simulation of heat conducted through copper traces and vias

- Material testing capabilities: enabled rapid evaluation of materials for optimal thermal performance without prototyping

- Customizable meshing approach: facilitated accurate modeling of complex geometries, which was essential for tightly packed designs, and enabled an extensive meshing optimization, which significantly reduced computation time without losing accuracy

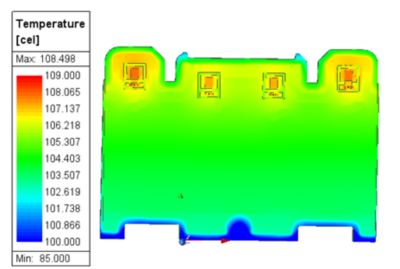

Thermal results of a section of the LED printed circuit board (PCB) inside the car surroundings

Benefits

Icepak software provided significant advantages throughout the development process.

- Accurate and fast thermal simulations: enabled the assessment of materials with differing thermal conductivities to optimize component cooling

- Time savings: eliminated the need for physical prototypes, accelerating the design cycle and saving more than two months in time

- Seamless ECAD Integration: enabled easy import of PCB designs using ODB++ format, facilitating detailed simulation of copper planes and via configurations

- Enhanced technical support: Provided ongoing assistance, ensuring the team could leverage the full capabilities of the software and become autonomous quickly

By utilizing Icepak software, the team successfully maintained low operating temperatures to enhance the reliability and lifespan of their automotive lighting solutions.

시작하기

엔지니어링 과제에 직면하고 있다면우리 팀이 도와드리겠습니다. 풍부한 경험과 혁신에 대한 헌신을 가지고 있는 우리에게 연락해 주십시오. 협력을 통해 엔지니어링 문제를 성장과 성공의 기회로 바꾸십시오. 지금 문의하기