-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

Food for Thought

Ansys Dimensions Staff

Buhler, a global leader in food processing solutions, is committed to applying advanced technology, including engineering simulation, at every opportunity to optimize its machinery for energy efficiency and high performance. According to Chief Technical Officer Ian Roberts, the company is focused not just on increasing sales and customer satisfaction via market-leading technologies — but on the urgent need to end world hunger, reduce waste and support sustainability across the worldwide food chain.

Buhler Chief Technical Officer Ian Roberts

We continually evaluate our technology tools, but have seen that Ansys offers an industry-leading software.

DIMENSIONS: Buhler’s product depth and its global reach are impressive. Do you think it is safe to say that everyone reading this magazine has been impacted by your products?

IAN ROBERTS: That’s probably a safe bet. Buhler makes state-of-the-art food processing equipment used around the globe. Sixty percent of the world’s grain, 30 percent of its rice and 60 percent of its chocolate are processed from raw materials into finished products via our equipment. Buhler does not produce any food products, but we provide the machinery, services and processing technologies that produce food for consumers in a safe, efficient, affordable way.

D: Recently, Buhler made a bold commitment to its customers, pledging to reduce energy consumption and waste in each customer’s value chain by 30 percent. Why is this an urgent requirement — and how do you plan to achieve this goal?

IR: Because Buhler plays a central role in the global food chain, we believe we have a duty to address global problems around food. Today 25% of greenhouse gases are produced by the food industry, including agriculture, and 70% of water usage is attributed to food production. At the same time, one-third of available food is wasted — while people in developing nations are starving.

Engineers make a critical contribution to improving the overall energy and environmental footprint of the global food industry. By decreasing the energy consumption of our equipment, Buhler can make the end-to-end supply chain more productive, more sustainable and more affordable. Not only can we save our customers money, but we can make a significant impact on some serious global problems. That is why we made a public commitment to dramatically cut energy usage.

A uniform die-flow is key to ensuring high product quality during the extrusion process. The temperature distribution, as shown here, influences flow behavior and final product properties.

D: How is engineering simulation, in particular, helping Buhler achieve its ambitious business goals?

IR: Buhler’s product development team leverages simulation to make all our equipment higher-performing in terms of process consistency, reliability, capacity, energy efficiency and other critical attributes. Our extruders, dryers and other machinery benefit from our simulation capabilities, which enable us to safely optimize our processes to achieve our strategic commitments.

It is important to note that food industry simulations are challenging. We need to look not only at how the equipment is working, but at how the physical changes we make will affect the finished food products. Food industry engineering means looking at suspensions, emulsions, mixtures and dynamic phase changes. We’re dealing with highly complex and evolving structures.

Since 2006, Buhler has been using Ansys simulation software, from mechanical solutions to fluids and processing tools. We chose Ansys because it is widely used by universities and across our industry. We continually evaluate our technology tools, but have seen that Ansys offers an industry-leading software. Ansys has been a valuable collaborator that, like Buhler, is committed to technology excellence and continuous advancement.

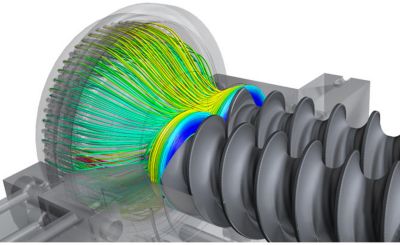

Buhler has used simulation software from ANSYS to improve the performance of key equipment components, including extruder screws like this one.

D: In addition to simulation, Buhler is a leader in applying the concept of digitalization and digital twins. Why is this technology important?

IR: Real-time monitoring — and intervention, when needed — represents the next frontier in achieving the highest performance and optimal energy efficiency for our processing equipment. If we can identify any operating issues and address them in real time, it will make an enormous impact on our ability to deliver on our customer promises. Eliminating downtime, reducing maintenance, monitoring energy usage and minimizing waste are hugely important in developing an efficient, affordable and sustainable global food chain.

With data visibility, we will be in a position to model the entire supply chain. We can gather huge volumes of data, store it using cloud technology and study it with today’s advanced analytics. We can apply lessons learned from our customers’ plants and use those insights to deliver better product systems and optimize the whole value chain. Via simulation, we can apply the governing rules of physics to our virtual models and study their response — leading to continuous improvements of our product designs, as well as predictive maintenance and repairs.

A number of food industry companies are investing in digital twins because they can help all of us address those urgent problems I mentioned before, such as availability of adequate nutrition and environmental impact. While these problems are daunting, we now have the digital technologies we need to tackle them.

Extruders are a critical part of the global food supply chain. By optimizing the extrusion process, the energy demands and the overall costs associated with this equipment will decrease while product quality increases.

D: Looking ahead, what is the future of the global food industry — and how will technology continue to play a role?

IR: In 2050, we will need to be able to feed 9.8 billion people. If we do nothing to change the way food is produced and distributed globally, there is a risk that not everyone will be able to access safe and affordable food. That is a sobering thought. It creates challenges for companies like Buhler, but it also creates an opportunity for innovation and leadership.

Advanced technology, including solving engineering challenges through simulation, is going to play an enormous role in optimizing the worldwide food supply by addressing operational challenges, efficiency, sustainability and waste reduction. As simulation and digital twins continue to grow in usage, the cost of operating the machinery and the next generation of processing technologies is going to come down, their quality and flexibility are going to improve, and these tools will be used by more companies of all sizes.

We’ve been encouraged by Ansys’ efforts to continuously improve its simulation solutions, as well as its outreach initiatives like its Startup Program, which place advanced tools within reach of every company. Each year, Buhler supports 60 small companies in the food industry, enabling them to develop innovations and commercialize their products.

The truth is, the problems of world hunger and sustainability are too large for one company to solve. Buhler is fortunate to work with technology leaders around the world like Ansys who develop transformational technologies. We value companies who function as true partners in improving our products and enabling us to make a greater contribution.

Simulation has helped accelerate Buhler’s product development efforts and fuel better financial results. Even more important, simulation, digital twins and other advanced technologies are creating a positive impact on the global food supply chain that improves the health, well-being and quality of life for billions of people.

BUHLER AT A GLANCE

| 2017 revenue: | CHF 2.7 billion |

| Number of employees: | 11,000 |

| Headquarters: | Uzwil, Switzerland |