-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

June 15, 2022

STMicroelectronics Accelerates Simulation and Analysis Time

Millimeter wave technology has opened the door to fast, close proximity wireless communications with high-data transfer rates. This enables fast data exchange for mobile device applications, and replacing short-range and board-to-board Ethernet connections with low-power 60 GHz in industrial designs.

However, simulating designs for high-frequency millimeter wave technology requires analyzing thousands of cases to guarantee antenna performance in these complex products. STMicroelectronics accelerated the design and validation of its own ST60 transceiver by cutting simulation and analysis times nearly in half. Learn more about how they did it in this new case study from Ansys.

STMicroelectronics is an independent silicon and electronics device manufacturer with headquarters in Switzerland and main design centers in France and Italy. The company has more than 100,000 customers, in addition to thousands of partners who collaborate to design and build advanced products, solutions, and ecosystems.

STMicroelectronics market offerings.

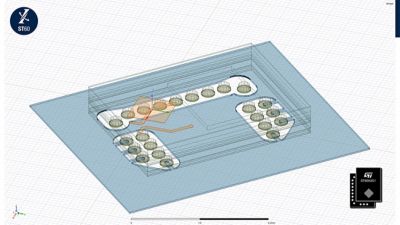

STMicroelectronics used Ansys HFSS coupled with high-performance computing (HPC) resources based on Intel® Xeon® Gold processors to accelerate development of its 60 GHz V-band ST 60 RF transceiver.

“The very high frequency of 60 GHz means that both environment and variation in the manufacturing process can significantly affect the performance of the antenna,” says Olivier Bayet, a leader in silicon packaging co-design, signal integrity, and power integrity at STMicroelectronics. “We need to ensure the robustness of the antenna design and make sure the package and system elements work together correctly to ensure fast, reliable data transmission.”

The close proximity of the radio frequency (RF) and digital processing components on a single silicon device present design and simulation challenges, and introduce complexity in integrating the various components of the wireless communication system. STMicroelectronics uses HPC resources to simulate and analyze the antenna in the same package as the silicon device, along with the component integration on the board.

That means analyzing hundreds or even thousands of cases — a process that took many days and affected time-to-market schedules.

According to the case study, STMicroelectronics needed to analyze and simulate thousands of cases to verify the complex antenna design. Using HFSS on HPE ProLiant Servers (equipped with Intel Xeon Gold processors), the company reduced the time it took to analyze more than 6,500 cases from 11 days to less than a week. This has accelerated the development cycle and reduced costs.

The team redesigned its workflow to perform more analyses and simulations during the design phase. This has shortened the development cycle and reduced the number of cases to analyze during the product validation phase. Further, the company has lowered costs by reducing the number of required samples. HFSS also identifies areas that may need further focus once physical samples are in hand.

The ability to simulate designs more quickly has helped the company address manufacturing tolerance errors earlier in the process, ensuring that the final product is reliable and provides optimal performance for customers.

To learn more about how Ansys HFSS and Intel Xeon Gold processors accelerated simulation at STMicroelectronics, download the case study here.