-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

Industries of all kinds, from aerospace and automotive to healthcare and industrial, are focusing on reducing their environmental footprint. Many companies are aiming for net-zero by 2050 or sooner, but they can’t do it alone. Actemium Energy AI — a high-end engineering group within Actemium, a part of VINCI Energies — delivers groundbreaking data analysis and optimization solutions using Ansys simulation and artificial intelligence (AI).

Actemium delivers safe, long-term solutions across the entire industrial life cycle — from design to maintenance. Combining deep expertise in automation, AI, and engineering with a sector-specific approach, Actemium optimizes performance and reduces energy consumption.

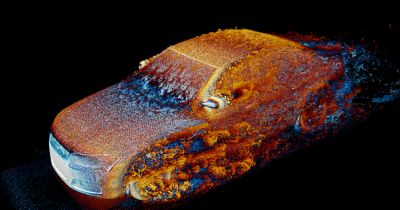

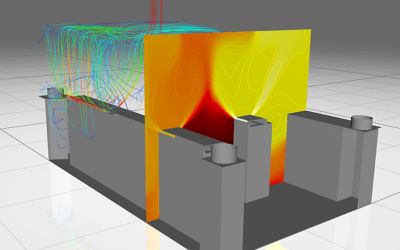

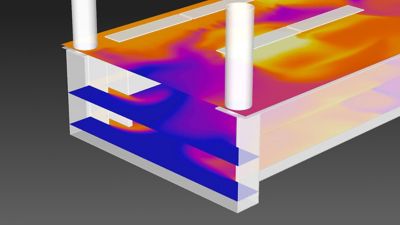

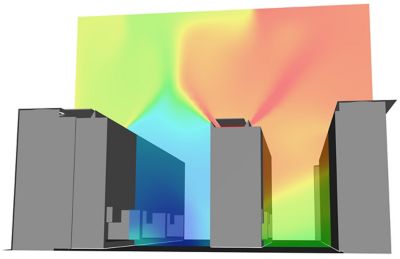

Actemium Energy AI creates a digital twin of a building based on computer-aided design (CAD) drawings or lidar scans. It then uses Ansys Fluent fluid simulation software to model ventilation, heating, radiation, and more, then couples the result with the HVAC system.

Actemium Energy AI focuses on energy management across the energy sector. Its team of engineers has expertise in physics and math, and many worked together in different sectors before Actemium.

“We are currently in a transition regarding environmental focus and technology,” says Leon Löwered, head of innovation and technology at Energy AI. “On one hand, we have more understanding and more technological solutions available to decrease our impact and footprint. On the other hand, there are many fields still increasing their negative impact on the environment. I am a firm believer that we need to work with technological solutions but also use them effectively and where they deliver the most value.”

Actemium uses simulation models to optimize HVAC changes, such as placement or direction of flow, as well as technical components, such as fans, heaters, and the control logic of how everything works together.

Building Optimization

Streamlining operations to lower energy consumption can be challenging. It requires analyzing large amounts of data, understanding complex systems, and making informed decisions. While manual optimization of these interactions is commonplace, this is time-consuming and impractical and often doesn’t find the full potential of the system.

Actemium Energy AI uses virtual modeling to quickly iterate on designs, exploring a wide range of solutions while simultaneously optimizing for multiple objectives. “The main goal is to create a solution for understanding a specific building’s potential — to base this not only on one corner case but to make it dependent on weather, time of year, time of day, operations, number of occupants, etc., then optimize solutions against impact, cost, and practicality of implementation,” Löwered says.

Actemium Energy AI creates a digital twin of the respective building based on computer-aided design (CAD) drawings or lidar scans. It then uses Ansys Fluent fluid simulation software to model ventilation, heating, radiation, and more, then couples the result with the HVAC system. With the models in place, it can optimize changes, such as placement or direction of flow, as well as technical components, such as fans, heaters, and the control logic of how everything works together.

Actemium Energy AI conducts large-scale simulations to evaluate the flow of heat and energy quickly and in a virtual environment.

These methods significantly reduce the need for expensive physical prototypes and are particularly beneficial during the early design stages. Optimization and AI enhance efficient designs, and potential issues can be detected early and addressed before any physical testing or installation takes place.

“A big part of our success as a team has been to combine different solvers and run them at the same time,” says Löwered. “We work with quite large simulation models where we combine system simulation with CAE simulation with control systems. And I think that is absolutely the pinpoint of the expertise that we have today.”

In 2024, Löwered and his team received the Technological Breakthrough Award as part of VINCI Energies’ Environment Awards. Using Fluent software, Actemium Energy AI enabled a large energy provider in Sweden to lower energy consumption of industrial cooling electrical components by 20%, resulting in the increased longevity of the systems.

“For these systems, you’re limited to what you can do because it needs to run all the time, so maintenance is problematic,” Löwered says. “Our solution showed that often there is much to gain even without system upgrades. We looked for small adjustments that made a big impact without rebuilding anything. This time, the customer did not need to buy new equipment, invest in a major rebuild, or shut down operations.”

While Löwered and his team have a history of using Fluent software, the deciding factor was the support they received from Ansys. “Ultimately, our choice of Ansys was influenced both by the quality of the tools, great scalability, and the strong relationships we have with the Ansys team,” says Löwered. “It gives us confidence for us to reach further.”

Learn more about how Fluent software can help reduce your environmental footprint.

Just for you. We have some additional resources you may enjoy.

“Ultimately, our choice of Ansys was influenced both by the quality of the tools, great scalability, and the strong relationships we have with the Ansys team.”

— Leon Löwered, head of innovation and technology, Energy AI

The Advantage Blog

The Ansys Advantage blog, featuring contributions from Ansys and other technology experts, keeps you updated on how Ansys simulation is powering innovation that drives human advancement.