-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

April 8, 2022

NanoSUN Delivers Hydrogen Fuel Safely at Scale with Ansys

As concerns rise over climate change, carbon dioxide (CO2) emissions, and other environmental pollutants, industries throughout the world are turning to hydrogen for a solution. A cleaner and safer alternative to fossil fuels, hydrogen fuel offers near-zero CO2 emissions when produced using renewable energy sources such as the electrolysis of water to release hydrogen or solar-based processing. While its production may vary, the applicability and benefit of “green” hydrogen remains the same across industries and private sectors from the aerospace and automotive industries to construction companies and beyond.

With such value to the environment and use in various fields, it is critical that clean hydrogen fuel is easily accessible and properly stored, distributed, and dispensed. At least that’s the top priority at NanoSUN, an award-winning engineering company based in the United Kingdom, dedicated to the development, manufacturing, and commercialization of green hydrogen refueling solutions.

And as a member of the Ansys Startup Program, NanoSUN is applying Ansys Fluent computational fluid dynamics (CFD) simulation software to make this happen more safely, efficiently, and at scale.

Getting Ahead with Simulation

Determined to bridge the gap between hydrogen suppliers and fuel-cell users, industry experts from the industrial gas and hydrogen fuel-cell sectors came together in 2017 to establish NanoSUN. The startup’s driving mission is to develop high-pressure, mobile, and cost-effective hydrogen storage, distribution, and dispensing solutions to the transport and mobility industries.

Still, hydrogen storage and its delivery present key challenges involving weight, volume, efficiency, safety, and cost. Further, government agencies and regulatory associations administer safety standards regarding the handling of hydrogen due to its high flammability coupled with its lower ignition energy. Essentially, it can ignite faster than gasoline or natural gas.

As a new company, resources at NanoSUN were limited. To meet challenges, adhere to safety regulations, and thrive in the industry, the team needed access to sophisticated engineering simulation software and tools. NanoSUN learned about the Ansys Startup Program through Ansys’ UK Channel Partner, Wilde Analysis Ltd, and became a member in early 2021. The program provides early-stage startups with affordable access to Ansys’ extensive portfolio of simulation solutions and support to help advance their businesses.

“It’s very important for us to have access to Ansys simulation software. It gives us the ability to create models, which gives us a better understanding of what we can expect from our systems, and it enables us to ensure that we’re creating a safe environment for the customer,” says Bethany Ladd, a graduate project engineer at NanoSUN. “Being a small company, until the past year and a half we haven’t had the funding for a proper commercial license, so the ability to jump on the Ansys Startup Program specifically gave us access where previously we wouldn’t have been able to afford these tools.”

Safety is key. With cylinders that hold around 419 kilograms of hydrogen at a rated pressure of 425 bar, fire is an active threat if appropriate ventilation is not in place or properly functioning.

This is where Ladd and her team apply Fluent the most, tracking and monitoring potential leaks within the refueling station’s venting system to prevent fire. Routine system checks are especially important at NanoSUN, where the refueling process engages multiple cylinders at once.

Most refueling companies use decant technology, which involves high pressure flowing to low pressure, from one cylinder to another, stopping when both are balanced. This state is referred to as equalization. However, this technique only partially fills the receiving cylinder.

Figure 1. This diagram depicts decant technology (left) versus cascade technology (right). NanoSUN uses cacade technology for hydrogen refueling.

NanoSUN’s signature Pioneer Hydrogen Refuelling Station (HRS) is a fully mobile, automated refueling solution that delivers hydrogen fuel directly to the point of use, facilitating more efficient and timely distribution. With NanoSUN’s cascading system built in the form factor of a standard 20-foot shipping container, the Pioneer HRS is a one-stop-shop to meet a client’s hydrogen refueling needs. The only thing needed to operate on site is a grounding connection and 230V power supply. Also, each unit is equipped with a battery backup.

Its innovative and convenient transport makes it available and suitable for a wide range of applications, including hydrogen buses, vans, and trucks; material handling; and construction equipment. It can also be used as a backup solution to traditional hydrogen fixed stations, for fleet demos, or as a network extender.

For vehicle fleets particularly, NanoSUN’s Pioneer HRS offers significant time and cost savings by eliminating the need to power additional compressors or electrolyzers at other stops, as shown in Figure 2.

Figure 2. This diagram illustrates the advantages of NanoSUN’s mobile Pioneer Hydrogen Refuelling Station (HRS) solutions (furthest left) in comparison to fixed HRS solutions (center and right).

Staying Ahead: Safety First with Ansys Fluent

Joining NanoSUN just six months ago, Ladd has already made an impact thanks to her experience using Ansys’ CFD software through the Ansys Academic Program as a student at the University of Cambridge in England. In this program, Ansys provides universities with discounted software while offering students free resources for self-learning, a combination that gives aspiring engineers an edge after graduation.

“When I started at NanoSUN, I wasn’t aware that they were intending to use CFD simulation. So, it was really interesting to be able to bring in what I had done at university through the Ansys Academic Program,” says Ladd. “And as CFD modeling is quite a new thing for NanoSUN — there’s probably only three people here who have experience in it — I think that’s part of the reason that I took the lead in that area of the calculations, being one of the only people with experience using Ansys Fluent.”

Ladd and fellow CFD-users are sharing their knowledge with the rest of the team, which comprises roughly 50 employees with new hires being recruited at a fast rate.

The bulk of Ladd’s role is to examine the engineering and safety calculations for NanoSUN’s refuelers, using Ansys Fluent to model scenarios such as hydrogen releases, or leaks, and potential combustion points throughout all stages of development. Since hydrogen is the lightest element and disperses at such a rapid pace, Ladd and her team need the right tools to thoroughly observe its behavior.

“We’ve been using Ansys Fluent for complex releases,” Ladd says. “With hydrogen being quite a buoyant gas, we use Fluent to look at things like if we were to have a leak into our container, how would we expect the flow to move around the other cylinders. I don’t think you could model these things without CFD.”

Additionally, Ladd analyzes potential combustion points to understand and gauge the direction and magnitude of potential releases or flames to calculate proper hazard distances, adhering to related hydrogen safety standards.

Some safe distances for hydrogen, as outlined by the British Compressed Gas Association, include 5 meters from flammable gas storage, sources of ignition, and fuel gas vent pipes; and 8 meters from employee offices or congregations of people, flammable liquids, and ventilator air intakes.

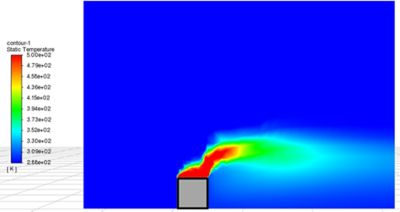

Such precautions are critical to Ladd’s work and consider variables such as temperature and radiation.

An example of this is when Ladd and her team use Ansys Fluent to model thermal pressure relief devices (TPRDs) to anticipate the temperature at which a fire may erupt due to a gas release.

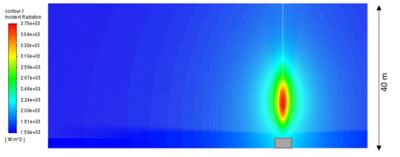

Using heat radiation guidelines given in thermal dosage from the European Industrial Gases Association (EIGA), Ladd applies Ansys Fluent to calculate horizontal distances between the point of hydrogen release and people working nearby. These thermal measurements incorporate dosage for various probabilities of injury, exposure durations, and thermal radiation intensities. With the radiation models built into Ansys Fluent, Ladd and her team compute the radiation incident at different distances from the release using the EIGA data and apply a safety factor of 50% to determine the minimum safe distance from the release.

Through these analyses, the engineers are able to predict, monitor, and prevent catastrophe.

Figure 3. Temperature profile illustrates the thermal release of nine cylinders.

Figure 4. Radiation profile illustrates the thermal release of nine cylinders.

For example, the team learned that if nine cylinders are released at once and the release is ignited, the radiative hazard distance is 19 meters. Alternatively, if only one cylinder is released through a TPRD the distance would only be 1.5 meters. Figures 3 and 4 show the outputs for a model of nine cylinders being released through the TPRD system assuming ignition.

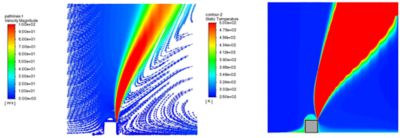

NanoSUN engineers also model the convective heat of TPRD releases, integrating wind at different speeds (shown in Figure 5) with 2D models and accounting for turbulence around the container with 3D models (shown in Figure 6).

Figure 5. Velocity colored streamlines and temperature contours for a 2D planar TPRD release model with 5 m/s wind coming from the left.

Figure 6. Temperature contours across the central plane of the model (through the hydrogen release point) for a 3D model with incident wind speed of 20 m/s from the left. In this graphic, the maximum temperature is set at 500 K to allow the temperature distribution across the system to be seen clearer.

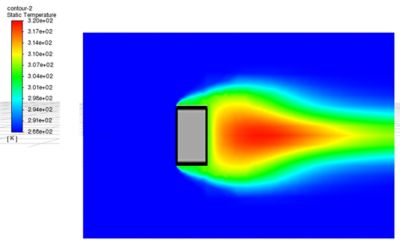

Further, the team observes temperature contours across horizontal planes at a constant height of 1.8 meters (shown in Figure 7), as recommended by the EIGA as the point of flammable effects at the average “head height.”

Beyond these capabilities, Ansys Fluent offers multiphase flow analysis and combustion modeling, providing insight into system performance and flow phenomena, which Ladd plans to explore next, taking full advantage of Ansys software and program offerings.

Figure 7. Temperature contours across a horizontal plane of constant height 1.8 meters. In this model, the wind at 20 meters per second is coming from the left-hand side of the graphic.

“I think I'd quite like to have a look at more detail, using Ansys Fluent to model the flow within the system, instead of external to the system if there’s a release,” says Ladd. “It would be very interesting to model flow into the cylinders and through orifices, such as how it reacts in plug flow.”

To learn more about the Ansys Startup Program, review additional information here.