-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

March 21, 2019

How to Build a Digital Twin from a Systems Simulation

Creating a systems level simulation is becoming an important part of product design. Systems simulations help designers assess how a whole product works before digging deeper into the development of each part.

Systems simulations also help engineers verify and validate products. They can even be the backbone for how to build digital twins, which track product performance in the field.

Digital twins can help the aerospace industry schedule engine maintenance.

With Ansys Twin Builder engineers can use systems simulations at every step of the development cycle.

In general, system simulations and digital twins help organizations accelerate the time to market and save money on warranty, insurance, unscheduled shutdowns and maintenance.

What Is a Systems Simulation?

A systems simulation is a collection of models, simulations and algorithms that predict how all the parts in a system will work together.

Systems simulations help the automotive industry ensure all

parts of a car work together.

As you build the system model, you will need to account for different physics. The fidelity of the model will improve as these physics are coupled into one simulation.

The challenge with creating a systems simulation is that the 3D models that predict the performance of each part take a considerable amount of time and computational resources to solve.

“We have to be more elegant with how we use those models,” says Kelly Morgan, lead application engineer at Ansys. “One solution is to use reduced order models (ROM) that can help system-level simulations run close to real-time.”

ROMs are simplifications of 3D models that preserve the essential information that is used for system simulations. Solving a ROM for a given input can be orders of magnitude faster than solving a 3D model.

This makes ROMs ideal for many applications, like design of experiments (DOE), systems simulations, digital twins and runtime generations of real-time applications. Twin Builder can connect third-party tools and 3D models within a systems simulation through reduced order models (ROM).

How to Build a Reduced Order Model

The first step in creating a systems simulation is to create all of the ROMs associated with the system. To create a ROM, engineers must first collect training data which captures the 3D model’s performance over its operational space. Twin Builder uses this training data to synthesize the ROM.

To capture the training data of this battery, you need to provide

a step-input to each cell with all the other cells turned off.

“For instance, say I’m creating a thermal ROM of a 28-cell battery,” says Morgan. “I turn on one cell and give it a step input. I then simulate the heat generation. Once I repeat the process for each cell, with the other 27 cells turned off, I will have my training data.”

Thanks to the step-input nature of the training data in this example, this ROM can estimate the high-fidelity model’s results for any given input. However, ROMs are limited by the training data collected. So, it’s important to capture the full operational space that the system simulation or digital twin might experience.

Additionally, if the model ever changes, then the training data will no longer be valid. Therefore, a new ROM must be created from training data collected from the updated model.

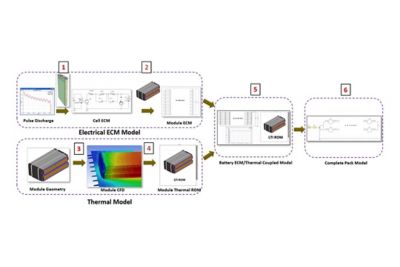

How to Build a Systems Simulation

To build the systems simulation, you have to start linking Reduced Order Models, algorithms and other physical data into a systems model. For instance, now that you have a thermal ROM of the battery, you will need to add more physics to the system model — such as the current and voltage relationship within the battery.

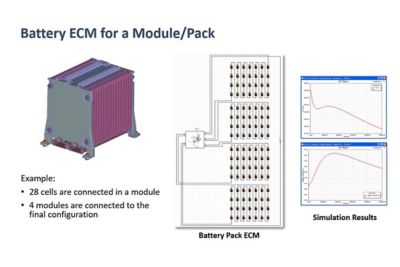

Systems level model of a battery

How to Build a System Model of a Battery

- Develop an equivalent circuit model (ECM) of the current/voltage relationship for each cell.

- Combine the ECM cells to form an ECM module.

- Perform a computational fluid dynamics (CFD) simulation of the battery’s thermal properties.

- Extract a Reduced Order Model from the CFD simulation.

- Use Ansys Twin Builder to couple the ROM and ECM module into a two-way multiphysics simulation.

- Link individual battery modules into a fully coupled battery pack to simulate the whole battery.

“Electrical engineers can think of a systems model like a circuit model, but when we talk about systems there is a multidomain aspect,” says Morgan. “Your system model might have electrical or thermal aspects and other mechanical configurations.”

Applications for the Systems Simulation and Digital Twins

The systems-level approach used to create a systems simulation ensures that it contains all the logic needed to represent its real-world companion. Engineers can use it to design a product, but it doesn’t need to end there.

Systems simulations and digital twins have applications outside of design.

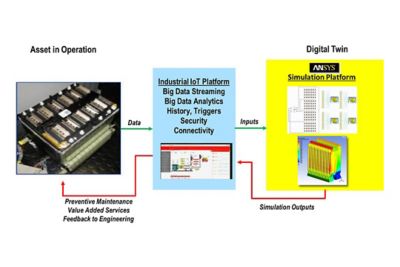

The systems simulation can be used throughout the product’s lifecycle. For instance, it can be packaged into a digital twin which connects sensors on an industrial internet of things (IIoT) platform.

The sensors can gather real-world data about the product the systems simulation digital twin represents. This data can then be fed into the digital twin from simulation to see how the real-world product is performing. The results from the digital twin can be used for scheduling, predictive maintenance and optimization applications.

Finally, the performance data captured by the digital twin can be sent back to the product’s design team. The team can use this data to come up with fixes for products in the field or improvements to the next iteration of the product.

To see in detail how to build a digital twin from simulation of a battery, watch: Developing Next-generation Batteries with 3D Physics and Systems Modeling and Simulation.