-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

August 25, 2021

How to Accelerate Ansys Fluent Simulations with Adaptive Meshing

Most computational fluid dynamics (CFD) simulations are solved by generating a hand-crafted mesh with local areas of refinement and coarsening. These refined or coarsened regions make sure there is a fine enough resolution to accurately capture results in important areas but also keep the total cell count manageable.

Although this method is a great way to ensure accuracy, there may be areas where there is too much refinement resulting in longer solve times or too little refinement resulting in less accurate results.

What if there was a method to automatically refine or coarsen the mesh ;based on the solution to get the most accurate results?

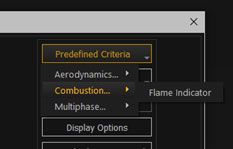

Best practices have now been embedded into the mesh adaption setup for combustion and multiphase applications.

There is, and that is known as adaptive meshing.

Polyhedral unstructured mesh adaption (PUMA) supports adaption of all 3D cell types in Ansys Fluent.

What is Adaptive Meshing?

Adaptive meshing is a method of refining the mesh of a simulation based on the solution. This scheme in Ansys Fluent enables you to start from a very coarse mesh and dynamically refine high-gradient regions.

Dynamic mesh adaption can be used in combination with the polyhedral unstructured mesh adaption (PUMA) method. PUMA does not rely on any templates for refinement, which does not limit this adaption method to specific element types. A mesh can also be coarsened after it has been refined.

Best practices for combustion and multiphase applications have been embedded in Ansys Fluent’s mesh adaption setup panel in the latest release, Ansys 2021 R2, resulting in:

- Up to 70% cell count reductions

- Up to 4X speed ups for steady state cases

Adaptive Meshing in Action

The Sandia Flame D is a fuel-rich turbulent diffusion methane/air jet flame test case. A pilot flame is injected in between the methane and air inflows. Two tests were done using two different coarse meshes to analyze their accuracy and final cell count difference.

The mesh adaption procedure automatically refined the mesh in critical regions to LES-level meshes, including the reaction zone, shear layer, and recirculation zone. We saw that both cases showed accurate results compared to experimental data.

Fluent’s adaptive meshing solution has shown a varying total cell count reduction of 30-70%, compared to a non-adapted fine LES mesh across a series of reacting flow cases.

Mesh adaption for combustion cases has been shown to reduce cell count by up to 70%

Spray Breakup

Mesh adaption can also be used to help accurately and efficiently simulate multiphase simulations, like that of a liquid jet breaking up. The volume of fluid (VOF) to discrete phase model (DPM) hybrid multiphase model is used in conjunction with dynamic mesh adaption. The VOF model tracks the liquid-gas interface while the DPM is a separate solver that tracks discrete particles suspended in a Eulerian phase.

The heart of this VOF to DPM model is an algorithm that looks for liquid lumps that get separated from the main liquid body of the spray and then converts them into point masses for further tracking. This method enables us to not track the interface of smaller drops and reduces the need to have very fine meshes.

A second important piece of this hybrid model is the dynamic mesh refinement and coarsening. Interface areas are tracked with fine mesh and once a blob is identified for transfer to the DPM model, the local mesh is coarsened to keep the cell count manageable.

To learn about all of the new enhancements in Fluent’s mesh adaption model, request the on-demand webinar, Ansys 2021 R2: Ansys Fluent Mesh Adaption Update.

Mesh adaption can be used with Ansys Fluent’s volume of fluid (VOF) to discrete phase model (DPM) model to efficiently solve multi-scale multiphase problems.