-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

March 22, 2023

How Simulation Helps Clean and Manage Water

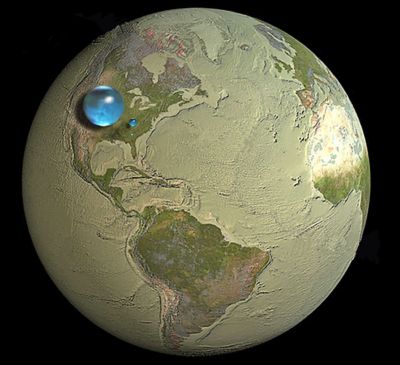

Today is World Water Day, which kicks off the United Nations (UN) 2023 Water Conference, held March 22-24 in New York. The day is a UN observance that “raises awareness and inspires action to tackle the global water crisis of the 2.2 billion people living without access to safe water,” according to the UN. Only about 3% of the Earth’s water is fresh, and most of that is trapped in ice or too polluted to use. That leaves about 1% of all our water readily available for the 7.9 billion+ people on Earth to drink, irrigate our land, and use in our industries. In the spirit of World Water Day, we’d like to share a few examples of how Ansys customers are using simulation to treat and manage water more effectively and develop sustainable solutions.

How Simulation Helps Make Water Safe to Drink

One way water is made safe to drink is via ultraviolet (UV) disinfection. Biodosimetry, which measures the inactivation of microorganisms due to UV radiation, is required to validate UV disinfection systems. Computational fluid dynamics (CFD) simulation, together with baseline bioassay results, can be used to evaluate reactor performance under site-specific inlet and outlet hydraulic conditions to alleviate costs associated with on-site testing. Sandia National Laboratory even has a website that provides guidance and protocols regarding CFD modeling that could facilitate potential future regulatory acceptance.

Spheres showing: all water (largest sphere); fresh liquid water in the ground, lakes, swamps, and rivers (mid-sized sphere); and fresh-water lakes and rivers (smallest sphere). Credit: Howard Perlman, USGS; globe illustration by Jack Cook, Woods Hole Oceanographic Institution (©); and Adam Nieman.

Another means to disinfect water is via chlorination. One municipality used Ansys CFD simulation solutions to help save hundreds of thousands of dollars in construction and testing costs when optimizing municipal drinking water treatment to meet U.S. Environmental Protection Agency (EPA) regulations for microbe inactivation. They were able to reduce chlorine disinfectant use and related byproducts while saving costs and reducing service interruptions when evaluating optimal baffle configuration before starting construction or retrofits.

Likewise, Ansys Fluent CFD simulation software was used with Ansys SpaceClaim 3D computer-aided design (CAD) software to develop effective mixing tanks for water purification by providing insight on how a tank mixer influences water oxygenation. The result was a faster turnaround per design iteration, which results in cost savings.

How Simulation Helps Return Wastewater to the Supply

After the water goes down the drain — whether via home, commercial, or industrial uses — many of us forget about it. However, that water has a long way to go before it is put back into the environment. It is collected and sent to wastewater treatment plants where it is cleaned via chemical and mechanical processes before being discharged. Simulation is put to work in this phase of the urban water cycle as well.

Wastewater treatment (WWT) is closely regulated by stringent government standards and is essential for sustainable processes. Indeed, industry leaders regard sustainability as a social responsibility, preventing pollution and reusing water as one of our most precious resources. The goal in such environmental initiatives is to extract waste materials as efficiently as possible by maximizing throughput rates using the least amount of energy.

Simulation has been used to simulate many water clarification processes that enable designers to accommodate more stringent effluent quality limits and increase throughput. For example, engineers used Ansys CFD solutions to help optimize water treatment by simulating a new dissolved air flotation (DAF) model, in which injected air bubbles are used to transport solids in water to the surface where they can be removed. Additionally, Ansys simulation is used to visualize and predict how sediment settles in the bottom of tanks to maximize their efficiency.

Ansys fluid dynamics simulation has also been used to help design and operate WWT systems in chemical processing plants. This represents a huge step forward in an industry that has traditionally relied on replicating past designs in new plants. One example focuses on the critical step in WWT operations in which screened and filtered liquid waste are treated in a large aeration basin — essentially a large tank with inlets for receiving raw materials and an outlet for draining off treated effluent. Naturally acclimated bacteria within the basin break down the organic compounds into a safe material. At the bottom of one of the basins, lengths of pipe with small sparging nozzles blow out air bubbles that transfer oxygen into the sludge to accelerate decomposition of the waste. The decomposition process in another basin is aided by the stirring action of floating aerators, whose impellers push liquid waste together with oxygen bubbles downward toward the basin floor to discourage settling and promote a more even distribution of bacterial action throughout the mixture.

Several variables — including gas–liquid flow, turbulence, dissolved oxygen, and biochemical reaction kinetics — were combined into a large-domain model consisting of 10 million computational cells representing the entire sludge basin. Subsequent comparison of the basin’s dissolved oxygen measurements with fluid dynamics calculations showed good correlation, thus validating the accuracy of the approach. This validation gave engineers confidence in using the model in a wide range of simulations that provided insight into design changes for optimizing the performance of the sludge basin. Using the CFD model, engineers could change a few key parameters to quickly study various alternative configurations in arriving at the most efficient design for meeting performance criteria. many of the simulations used Fluent to create isosurfaces that define boundaries separating regions of various oxygen levels or liquid velocities, for example. Such displays are helpful in understanding the characteristics of a complex system undergoing multiple behaviors.

How Simulation Helps Manage Water

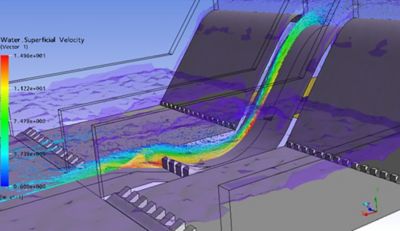

While fresh water is only a very small percentage of Earth’s overall water supply, it can still be too much of a good thing. Ansys simulations are used to represent complex fluid-structure-soil interactions to aid environmental risk assessments to prevent flooding, as well as improve water management by optimizing stormwater systems, spillways, culverts, and dams.

Section plane view of flow over a spillway.

Runoff from sediment in stormwater contributes to polluted rivers, lakes, and estuaries. One customer employed Ansys simulation to save weeks of design time and reduce the cost of physical prototyping by more than 80% by simulating a new design. Other customers used Fluent simulations to improve the internal hydrodynamics of water basins to mitigate pollutants in rainfall runoff and simulate water flow and turbulence in vegetated stormwater ponds, increasing their treatment capabilities.

Ansys CFD simulations have even been used to evaluate water conditions that are safe for fishways that enable fish like salmon and steelhead trout to migrate past dams. Power plants also use Ansys simulation to evaluate the environmental impact of discharging cooling water from thermal and nuclear power plants into nearby water reservoirs, rivers, and lakes.

When it comes to water management, structural considerations often need to be considered as well. For example, Ansys Mechanical and Ansys LS-DYNA were used with CFD simulation to evaluate the factors that influence the dynamic response of dams, such as the foundation soil, aspects of the water reservoir, and sediments at the reservoir bottom. Another Ansys customer used a simulation-driven design process to improve spillway and culvert performance ratings by optimizing hydrological modeling and water supply planning while evaluating restoration performance measures.

As you can see, the water we use is reused again and again, so optimized treatment and management processes in every aspect of that use are critical. Ansys is proud to help our customers use simulation to improve how they conserve, treat, and manage water.

Learn more about World Water Day and Ansys fluid simulation software.