-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

February 21, 2024

Turquoise Hydrogen: The Future of Hydrogen Energy

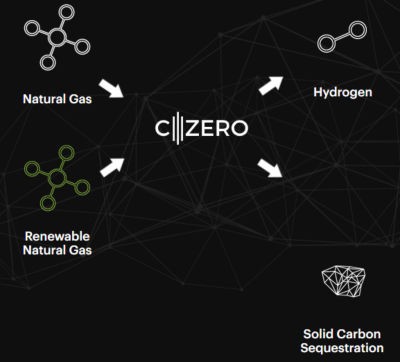

There’s a huge focus today on green energy, but one California startup is leveraging Ansys solutions to develop a unique “turquoise” fuel source. C-Zero relies on engineering simulation to optimize its innovative process for producing hydrogen by splitting methane — the primary component of natural gas — into hydrogen gas and solid carbon.

C-Zero's process, a version of methane pyrolysis, was developed and demonstrated by Eric McFarland, a chemical engineering professor at the University of California, Santa Barbara, who is now C-Zero’s Chief Technology Officer. Backed by funding from the U.S. Department of Energy, along with investors like Bill Gates’ Breakthrough Energy Ventures, C-Zero is working to commercialize its process for large-scale clean hydrogen production. A pilot facility, capable of producing 400 kg of hydrogen per day, will be operational in early 2024.

Sam Shaner, C-Zero’s Technical Director of R&D, was the company’s first technical hire in 2019. Today he’s charged with delivering on the promise of low-cost, zero-emissions hydrogen production.

“Natural gas is a plentiful, low-cost energy source that already provides about a quarter of the world’s energy — so the opportunity is enormous,” Shaner notes. “If we can decarbonize natural gas, it can be transformed into pure hydrogen, a more sustainable fuel source. Natural gas distributors and consumers can capitalize on its ready availability for applications like electrical generation, without being concerned about CO2 production.”

What is Turquoise Hydrogen?

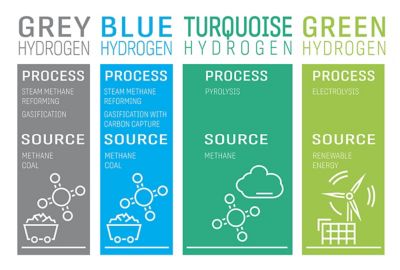

Turquoise hydrogren is produced from methane pyrolysis along with solid carbon in a process that does not produce any carbon dioxide. This process uses natural gas as feedstock, which is abundantly available worldwide and is a widely used fossil fuel. Methane pyrolysis provides an effective pathway to decarbonize natural gas to produce clean hydrogen and no CO2 footprint.

C-Zero’s process results in “turquoise” hydrogen, which combines the benefits of other existing forms of hydrogen production. The color is based not on its physical appearance, but on its place on the spectrum between traditional hydrogen delivery processes (gray), traditional hydrogen delivery processes with carbon capture (blue), and renewable-energy-based hydrogen production (green).

C-Zero says the “turquoise” hydrogen produced its patented process offers significant cost and energy efficiency benefits over traditional alternatives.

“Green” hydrogen, produced via water-based electrolysis powered by renewable electricity, is carbon-neutral, but expensive to manufacture. “Blue” hydrogen is produced using steam methane reformation of natural gas, an energy-intensive process that requires the added step of carbon capture. In addition, it produces carbon in a gaseous form, which is a pollutant.

In contrast, C-Zero’s methane pyrolysis process has two outcomes: pure hydrogen gas and high-density solid carbon that can be sequestered or used in a variety of industrial applications. According to Shaner, methane pyrolysis consumes seven times less energy than electrolysis — making turquoise hydrogen the clear winner over blue and green alternatives.

C-Zero’s methane pyrolysis method splits natural gas into two components: pure hydrogen gas and solid carbon.

Benefits of Turquoise Hydrogen

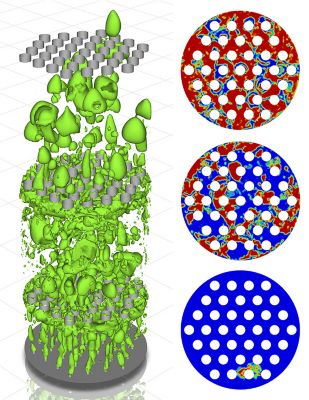

While C-Zero’s process makes perfect sense from environmental and business perspectives, methane pyrolysis is a complex, intense process that leverages thermocatalysis to split natural gas into two components. Methane gas is fed into a reactor chamber filled with a molten media, where it’s heated to temperatures exceeding 1000 °C. Hydrogen emerges in the form of gas bubbles, while carbon is extracted in solid form.

This process is characterized by multiple physical forces — including thermal effects, fluidic effects, structural effects, and gas–liquid exchanges. Before C-Zero can commercialize turquoise hydrogen on a large scale, the process must be perfected for maximum energy efficiency and optimal heat transfer. The reactor’s materials and geometry must withstand extreme structural and thermal forces, while also being optimized for minimal size and weight. In addition, carbon molecules have a pesky tendency to deposit on the walls of the reactor during pyrolysis — so both the process and the vessel must be designed to minimize those effects.

“It’s impossible to see inside the reactor vessel and observe processes like heating, mixing, separation, and deposition firsthand,” Shaner points out. “So we need to simulate that complex process in a virtual environment to make it visible. Since C-Zero was founded, Ansys has played a critical role in helping us see and understand the flow, thermal, and mechanical characteristics of the methane pyrolysis reactor, which is at the heart of our company’s value proposition.”

Left: Velocity vectors showing bubble volume fraction and velocity distribution across the cross-sectional area at different elevations within bubble column. Right: Bubbles rising through molten media, creating sloshing and dynamic pressure on walls. Ansys simulations estimate the dynamic pressure created on the walls in this hot molten media column and help to design the internal structure to mitigate the same.

Simulating Turquoise Hydrogen Production

When Amit Mahulkar joined C-Zero as a Senior Mechanical Thermal Systems Scientist in 2021, it was no surprise when he was tasked to use Ansys Fluent and Ansys Mechanical to optimize the company’s feed injection, mixing, and separation processes. He had been using Ansys solutions for years in his undergraduate, graduate, and doctoral studies — as well as in his previous energy research positions.

“Ansys is the industry standard for both fluidic and structural simulations, as well as modeling the complex interactions between structures and fluids,” says Mahulkar. “It helps us perfect the methane pyrolysis process and get it ready for large-scale production. With Ansys, we’re able to push the limits of what’s possible, with no human safety risks, very little physical prototyping, a relatively low product development cost, and rapid design iteration.”

Mahulkar is using Fluent to model and optimize the process of injecting natural gas into a molten, viscous material that’s eight times denser than water. Transient simulations enable him to optimize the process of bubble formation, perfect fluid flows to minimize sloshing, identify and eliminate high-temperature zones, and minimize heat loss to ensure process consistency.

Mechanical helps Mahulkar design the right structure for the pyrolysis reactor to support the high temperatures of thermocatalysis, while also addressing problems like carbon deposition.

“If carbon has a natural tendency to deposit on the reactor walls, then we have to account for that,” he explains. “We have to use more expensive materials in those places where solid carbon is likely to collect.”

According to Mahulkar, it would be virtually impossible to optimize the process of methane pyrolysis without applying simulation tools from Ansys.

“We’re talking about reactions that are occurring inside a closed vessel, using an opaque molten media that’s 1000 °C,” he points out. “Ansys simulation allows us to take temporal and spatial measurements. It allows us to visualize the injection, mixing, separation, and deposition processes. It allows us to study complex multiphysics problems like heat loss and bubble formation, along with chemical reactions. I can’t imagine doing my job without Ansys.”

Both Shaner and Mahulkar are grateful for the chance to access a full range of Ansys capabilities, as well as Ansys Cloud, through the Ansys Startup Program.

Formation, breakage, and coalescence of bubbles in a bubble column with trays. Gas bubbles are shown in green. Contours show the fraction of tray surface covered with gas. Ansys simulations determine the effectiveness of the tray design for dispersing gas bubbles.

“As a small company that’s still proving its concept, we simply don’t have the resources to create an internal computing cluster or invest in traditional licensing,” Shaner says. “The Ansys Startup Program has given us the capabilities we need to optimize our process and get our first pilot facility up and running. That’s invaluable in commercializing this technology and bringing turquoise hydrogen to energy consumers around the world.”

“One of the great things about Ansys is the depth and breadth of its simulation capabilities,” Mahulkar adds. “As our needs evolve, we’ll be studying different, increasingly complex problems — and Ansys will be right there with the solutions we need. C-Zero is growing, and the flexible Ansys tool kit will continue to support that growth. Our Ansys footprint will expand right along with our company.”