-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

November 9, 2023

In Pursuit of Perfection: Ferrari Turns to Simulation to Refine Vehicle Design

Tune into to the third installment of “Driven by Simulation” to see how the racing icon relies on simulation to accelerate development of new car concepts and guide on-track decision-making.

Some say that to hear the purr of an idling Ferrari as you sit behind the wheel is an experience like no other. In the words of one of the most iconic brands in racing history, the Prancing Horse emblem represents the ultimate in exclusivity, performance, and prestige built on decades of sporting success and an unwavering sense of style.

That was part of Enzo Ferrari’s vision for the brand when he founded the company more than 70 years ago. A race car driver and highly successful entrepreneur, he was fueled by an undying passion for motorsport and an unwavering dedication to perfection in vehicle design. This tradition plays out today at the Ferrari plant in Maranello, Italy. Some of the greatest sports cars of all time were produced in Maranello, including the 250 GTO, the Testarossa, the F40, the Enzo, and the LaFerrari.

Each Ferrari is engineered with precision, then lovingly assembled by hand over several months. The process has been described as “a careful blend of traditional crafting techniques and technology.” One of those technologies — simulation — is used during the design and development of Ferrari race cars in pursuit of championships, as well as to maintain the brand’s legacy with an eye on Fédération Internationale de l’Automobile (FIA) industry standards. The FIA is the governing body of motor sport.

Since 1998, Ferrari has partnered with Ansys to ensure that it is constantly adopting the most advanced simulation capabilities and best-in-class engineering simulation practices both on and off the track.

Harnessing the Power of Data with Simulation

For more than 30 years, the Ferrari Challenge Trofeo Pirelli has brought together dream cars and Ferrari clients on four continents to compete in top-level sprint races. It’s a unique, single-marque championship that delivers all the on-track thrills while upholding technical professionalism and safety. Drivers are grouped into four separate categories by skill level — from professional drivers to gentlemen racers.

During this event, race cars exchange and process high levels of real-time data quickly to inform their performance on the track. Using simulation during telemetric analysis — the analysis of in situ measurements and other on-board vehicle data — helps Ferrari engineers make real-time, informed decisions.

With the help of simulation, virtually every aspect of the vehicle is analyzed, including the engine and tires, as well as structural and aerodynamic performance. This information is essential to understanding driver performance and vehicle reliability during a race and can include team access to critical real-time data regarding mechanical issues, tire punctures, and other systems to help keep a driver safe.

To ensure that data is successfully transmitted from cars as they speed around different tracks, Ferrari uses simulation software like Ansys HFSS to choose and onboard components vital to vehicle connectivity. A successful 5G antenna assessment, for example, might hinge on its beam-steering capability to establish a communication link with a data recorder. The stronger the link, the stronger the flow of data, which is extremely important when both the pit box and the pilot must come together to make decisions quickly.

Ferrari Competizioni GT uses 5G and Ansys simulation technology to boost connectivity and optimize data flow.

“The Ferrari Challenge has always been a very innovative championship,” says Davide Piccinini, vehicle engineering manager for Ferrari. “And for this reason, we always seek solutions that give great driving experience to our pilots. And for this reason, we make extensive use of simulation technologies offered by Ansys, especially for 5G antenna because it allows communication between the pilot and the engineer in the (pit) box.”

Ferrari and Ansys began collaborating in 1998, when they were pioneering simulation tools to support the work of aerodynamicists.

Simulation Helps Optimize Ferrari’s Winning Aerodynamic Designs

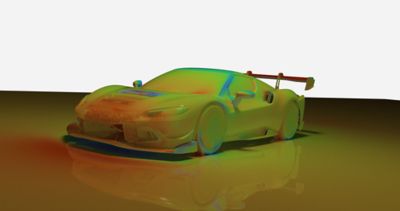

Ansys simulation supports what is today considered by Ferrari to be an important element of the brand’s contemporary design aesthetic — namely aerodynamics.

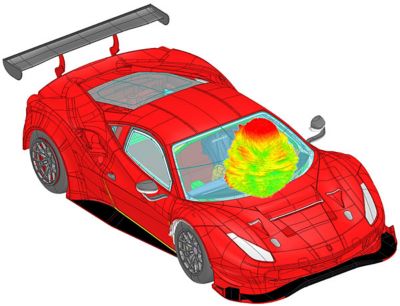

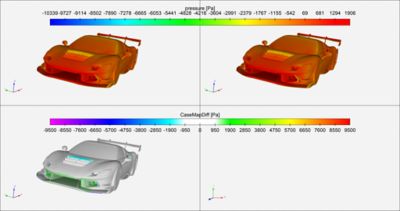

For years, Ferrari has used Ansys Fluent computational fluid dynamics (CFD) software to supplement wind tunnel testing in the optimization of the aerodynamics of its race cars. In Fluent, Ferrari engineers can generate a fully realized, virtual 3D vehicle design to test a large number of geometrical variations of its vehicle designs faster, which has helped the automaker cut its design cycles by more than half.

Of course, intensely competitive racing environments require Ferrari engineers to identify the most innovative engineering tools available to conform to an extremely aggressive development schedule. Adding Ansys Fluent Mosaic-enabled Poly-hexacore CFD meshing technology into the mix helps accelerate meshing time, a critical step in the simulation workflow. It also enables modeling of more complex physical phenomena, such as turbulence, and helps predict wind tunnel test results with a high degree of accuracy.

“Simulation plays an important role in car development because it allows us to make decisions in very tight timeframes dictated by the competitions that, indeed, between races, we have little time to intervene,” says Piccinini. “So, simulations, even in car development, help us progress and implement these solutions in the car. And the decision on a track … can greatly influence the final results. If you make the wrong decision, it’s easy to end up in the middle of the pack … On the other hand, you make the right choice with simulation done with Ansys.”

Buckle Up for More Racing Excitement in Episode Three of “Driven By Simulation”

Tune in to the latest installment of our exciting new docuseries “Driven by Simulation.” During episode three, you’ll get a more personal view of Ferrari, including insights from Ferrari engineers as they share how simulation is shaping race cars of the future.