-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

August 4, 2022

A Glimpse into Deep Space with Extreme Optical Engineering

In the past few decades, optical science has pushed far beyond the foundations originally laid by Galileo and Newton 400 years ago. The planned deployment of new ground- and space-based telescopes dedicated to seeing farther into deep space in more detail than ever before will provide astronomers with increased opportunities to find Earth-like exoplanets and answer questions about how galaxies formed and evolved billions of years ago. To help make those plans a reality, researchers at the University of Arizona are using Ansys structural and optical simulation software in the design, fabrication, and testing of the next generation of telescope optics that will enable another giant leap for our knowledge of the cosmos.

The University of Arizona is at the center of several major telescope research and development projects. With its world-leading large optics laboratories and the Wyant College of Optical Sciences, researchers are at the forefront of creating the optical components that will power ground-based systems like the Giant Magellan Telescope and future space-based concepts like the proposed OASIS space observatory.

Artist's concept of the completed Giant Magellan Telescope, which will be situated in the Atacama Desert some 115 km (71 mi) north-northeast of La Serena, Chile. Courtesy of Giant Magellan Telescope – GMTO Corporation

The Largest Mirrors Ever Built, Times Seven!

Upon its expected completion in the late 2020s, the Giant Magellan Telescope (GMT) will be among the largest ground-based telescopes ever constructed. GMT is the product of an international consortium of 13 universities and scientific institutes across five continents. The structure itself will reside on Las Campanas Peak in Chile’s Atacama Desert at an elevation of about 2,500 m (8,200 ft) above sea level. The location was chosen for its dry climate and remoteness that will reduce optical interference from light, air, and humidity.

To capture enough photons to see billions of light years across the universe with enough clarity, the GMT project requires the creation of seven enormous mirror segments — a center segment and six off-axis segments that surround it — that will comprise the primary optics. Due to the size of the light collection area, the image resolution will be about 10 times greater than the Hubble Space Telescope launched in 1990, and about four times greater than the James Webb Space Telescope (JWST) that was successfully launched in 2021.

Each GMT mirror segment is 8.4 m (28 ft) in diameter, weighs about 16 tons and takes about six years to complete, including the casting, polishing, and testing processes. These are the largest mirrors in the world and are produced at the Richard F. Caris Mirror Lab at the University of Arizona. The first two segments have been completed, while segments 3, 4, 5, and 6 have all been cast and are in various stages of surface polishing and measurement.

A major challenge of using such a large mirror is bending caused by its own weight and by wind forces. The mirror can only bend by about 100 nanometers (nm) before the images become too blurry, so balancing the stiffness with the weight was of paramount importance. Using Ansys Mechanical software, the researchers modeled the mirror structure to predict the expected deformation of the optical surface. With the initial structural analysis complete, they then used Zemax’s Structural, Thermal, Analysis and Results (STAR) module to load the finite element results from Mechanical into Ansys Zemax OpticStudio, where they could simulate the optical performance of each mirror segment due to the surface deformation.

Following the full optomechanical analysis, the team designed the mirror’s central structure as a lightweight honeycomb, consisting of several 0.5 -inch-thick ribs in a hexagonal pattern holding together the 1-inch-thick glass facesheet and backsheet.1 To cast the rough mirror, chunks of borosilicate glass are loaded over a mold inside a furnace spinning at 5 rpm, which forces the glass up the sides of the mold as it melts into the concave parabolic shape that is required to focus light from a distant celestial object. Over the next three months, the furnace slowly stops rotating and the glass cools to room temperature.

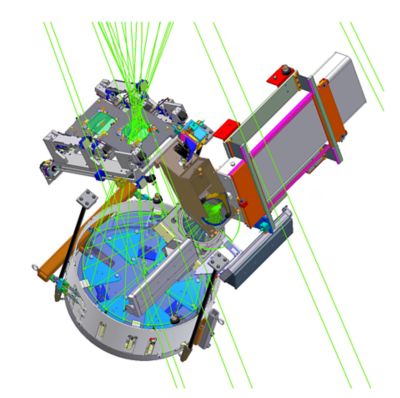

Computer-generated hologram (CGH)-based interferometry configuration for the 8.4-m diameter Giant Magellan Telescope (GMT) off-axis segment surface shape metrology.

Once cooled, the next step is the long process of polishing the mirror to the requisite optical quality and surface figuring to achieve the desired shape, which requires an accuracy of a small fraction of the wavelength of light being received. The surface has to match an ideal off-axis (or on-axis for the center segment) parabolic surface to within 25 nm, which is smaller than one-thousandth the width of a human hair. Because the surface is aspherical, the team needed to have very fine local control over the shape. Using two different types of polishing tools at different locations on the mirror surface, they selectively target high spots of different scales while the abrasive material slowly removes the glass, molecule by molecule.

Being deterministic is the essential component of this precision optical figuring exercise. If the researchers could not model, simulate, optimize, and predict the glass material removal prior to a typical week-long polishing and figuring session, they would not know whether they were removing the right amount of material from the right locations. The duration to manufacture each mirror segment would then be much longer than six years and delay the program by many more years, or even decades.

To avoid such a trial-and-error scenario, the team measured the mirror's surface shape using laser interferometry and visible deflectometry after each polishing session. Using Ansys Mechanical and other structural analysis tools, they then modeled the gravitational and thermal deformation of the surface during the measurement and compensated for that predicted deformation in the measurement surface errors. Thus, the team focused the next rounds of continuing optical figuring runs on meaningful optical surface error correction without being confused with optomechanical surface bending effects.

Before any surface figuring and polishing begins, the surface is only accurate to within about 30 μm (30,000 nm), which is three orders of magnitude away from the target accuracy of 25 nm. Improvements to the polishing process, aided greatly by simulation, helped the team reduce the calendar time required to achieve a specific surface accuracy measurement by a factor of four. For segment 1, it took about 300 days of polishing to improve the accuracy from 2400 nm to 320 nm. For segment 2, the research team achieved that same result in just 70 days, and they expect it to be even faster for the next segments.2

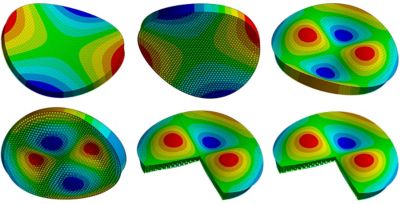

Simulation results showing the two bending mode shapes of the 8.4m GMT off-axis primary mirror segment (in different views).

Oasis Space Observatory: Is There Water Out There?

One of the practical limits for space-based telescopes has been the size and weight of the optics. Issues like wind and light pollution are removed, but you must be able to fit the components inside a rocket and lift them into orbit. The full mirror diameter of the James Webb Space Telescope is 6.5 m— smaller than a single GMT primary mirror — and it still had to launch with its 18 hexagonal segments folded up. To launch anything with much larger optics will require using radically different materials.

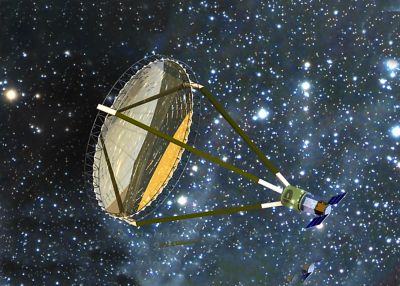

3D rendering image of the OASIS Space Terahertz Telescope observing in the submillimeter to far-infrared.

In response to a recent NASA Medium-Class Explorers opportunity, the Orbiting Astronomical Satellite for Investigating Stellar Systems (OASIS) telescope is a concept for a space-based observatory with a primary mirror (or antenna) made of a metallized polymer membrane — effectively a gigantic mylar balloon. When fully deployed from its spacecraft, the reflector would be inflated to a diameter of up to 20 meters (66 feet). Together with active and/or adaptive optics techniques, OASIS will be designed to provide high-resolution observations at terahertz frequencies in the far infrared spectrum (around 660 μm to 63 μm). This will allow it to search for water both in local asteroids and on planets or moons in other star systems.

Because the primary mirror is an inflatable material, its shape is a function of pressure, which is a unique challenge for the optical design. Using an in-house analytical model, the Arizona researchers evaluated a parametric solution space to determine the location and size of the telescope optics such as the secondary mirror that will be needed to correct for the changing surface profile of the antenna. In parallel, the team performed ray tracing analysis using Zemax OpticStudio to predict the photon collecting area of the antenna. The OpticStudio results verified that both analytical and numerical membrane models are suitable to accurately predict the optical design parameters of the inflatable optical surface.3

If the project is selected by NASA, the envisioned launch date will be in 2028, whereby OASIS will operate in an orbit around the L2 Lagrange point. This is one of the locations where a satellite can be positioned so that the gravity from the Sun and Earth balances the satellite’s motion. The L2 point is almost a million miles farther out than Earth from the Sun, and also the celestial neighborhood of the JWST. Other orbits are also being considered as more science cases are being discussed and technology developments are actively achieved.

Inflatable optical design solution space contour plots of as-designed models for the OASIS observation band 1. Effective photon collection area and diameters of M2 and M3 mirrors are plotted as a function of A1 radius of curvature and entrance pupil diameter (EPD).

Countdown to Deployment

Many of the Arizona team working on GMT and the OASIS concept were inspired by the success of the Hubble program over the past thirty years and the famous deep space images it revealed to humanity. The gifts from Hubble were only possible due to the decades of optical science and engineering that came before to enable its successful launch and operation. Indeed, the team shares a dream of passing along a similar gift to future generations as both projects get closer to realization at the end of this decade.

References

- B. Martin and D. Kim, “How do you build a mirror for one of the world’s biggest telescopes?,” The Conversation, 15 Jan. 2016, theconversation.com/how-do-you-build-a-mirror-for-one-of-the-worlds-biggest-telescopes-49927. Accessed 15 Apr. 2022.

- H. Martin et al., “Manufacture of primary mirror segments for the Giant Magellan Telescope,” Proc. SPIE 10706, Advances in Optical and Mechanical Technologies for Telescopes and Instrumentation III, 107060V (2018).

- S. Sirsi et al., “Parametric design study of the Orbiting Astronomical Satellite for Investigating Stellar Systems (OASIS) space telescope,” Proc. SPIE 11820, Astronomical Optics: Design, Manufacture, and Test of Space and Ground Systems III, 118200Q (2021).