-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

January 28, 2021

Axiom Space Is Using Ansys Simulations to Build the First Commercial Space Station

The International Space Station (ISS), after 20 years of use by hundreds of astronauts, is only guaranteed funding to keep it running through 2024. Just as NASA opened the way for commercial entrepreneurs like SpaceX and Blue Origin to make the next generation of rocket boosters to lift people and payloads into orbit, it is now looking for entrepreneurs to take over the space station and build its replacement.

Axiom Space, a member of the Ansys Startup Program, is stepping up to the challenge.

Axiom Space was founded in 2016 by Michael Suffredini, ISS Program Manager for NASA from 2005 to 2015, and Dr. Kam Ghaffarian, founder of Stinger Ghaffarian Technologies, Inc., NASA’s second-largest engineering services contractor. In early 2020, Axiom Space won the NASA contract to build the first commercial space station, initially attached to the forward Node of the ISS. The countdown on their website to the launch of Axiom Hub One, a space module that will travel to the ISS, is 3 years 10 months and 1 day as this blog is being written.

Ansys will be helping them all along this timeline. Axiom engineers are trying to solve the toughest structural and fluid flow challenges they face using Ansys Mechanical and Ansys Fluent software obtained through the Ansys Startup Program.

“As a startup you are always looking for deals, because funding is limited in the early years,” says Matt Ondler, Chief Technology Officer of Axiom. “The Ansys Startup Program has proven to be a great deal for us.”

Designing and Simulating a Unique Thruster

Axiom engineers are relying on an innovative thruster powered by oxygen and methane to propel Axiom Hub One to the ISS. They will get a boost into space from a SpaceX or Blue Origin launcher, then, once in orbit, they will depend on this new thruster to maneuver them to the ISS.

The oxygen-methane thruster solves two challenges: it replaces the toxic monomethyl hydrazine fuel that has traditionally been used to maneuver shuttle craft to date, and the methane fuel can be created throughout the mission from an unexpected source.

“We can make rocket fuel out of exhaled breath from the crew,” Ondler says. Doing this relies on the Sabatier process, which uses a nickel catalyst to react hydrogen with carbon dioxide from the astronaut’s breath to produce methane and water. It has already been tested and proven to work in ISS experiments.

“Studies show that with a crew of about six we can produce enough methane to meet all of our propellant needs,” Ondler says. “The technology has long-term applications. There’s a lot of CO2 on Mars, so you could create the rocket fuel to bring you home from a Mars mission instead of carrying all that fuel with you.”

But nobody has ever flown an oxygen-methane-powered spacecraft before, so they are using Ansys Fluent to help in the design. One of the challenges of the thruster is maximizing the efficiency, which is measured by a variable called the “specific impulse.” This is just the total impulse (the average thrust force times the total firing duration) divided by the weight of the propellant used. The higher the specific impulse, the less fuel is consumed for a particular change of velocity.

One step in maximizing the specific impulse is to mix the methane and oxygen molecules as thoroughly as possible. An injector plate that causes the molecules to swirl and mix is an art and a science, according to Ondler. “So we run Ansys Fluent and get simulation results and we build that solution and test it to see how it works and then iterate between simulation and testing,” he says. “Maximizing the specific impulse of the thrusters trickles through the whole system — the more efficient the specific impulse the smaller you can make the fuel tanks; the smaller you can make the tanks the more margin you have on the vehicle itself and it just propagates through the whole spacecraft.”

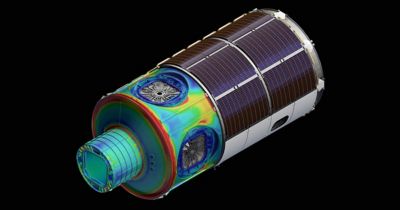

Ansys stress analysis results are driving the design of the first Axiom module (AxH1)

Space Station Structural Considerations

An Axiom Hub, which will attach to the ISS and to any future commercial space station they build, is a living and research space for the astronauts who will occupy it. It is 60 feet long by 15 feet in diameter and weighs close to 60,000 pounds.

“These modules are massive pieces of hardware, and when you have pressure inside and vacuum outside they stretch and swell and bend,” Ondler says. “We're using Ansys Mechanical to help us understand all those attributes: how it bends, where the stress points are, where we might need to change the design.”

Structural loads will vary depending on whether the module is on the ground, being transported to the launch site, or experiencing the high forces of launch. Thermal loads can also cause major structural challenges in space because the side of the module facing the sun might be several hundred degrees hotter than the side facing away from it. Thermal expansion and contraction in cases like this could be enough to cause separation of the structure or buckling if the module is not designed correctly. Ansys Mechanical will help to make sure this doesn’t happen.

“Our experience with Ansys Mechanical and Fluent has been very, very positive,” Ondler says. “The interface has been easy to learn and easy to use. The Ansys Startup Program has given us access to much needed simulation tools.”

A rendering of an Axiom space station interior

Private Space Stations Are Critical

Designing, manufacturing and flying the hubs to the ISS is the immediate goal. Ultimately, Axiom Space will separate from the ISS and become its own independent space station. It will be the first fully commercial space station. After separation, Axiom will continue to add modules, some of which might be custom built for specific space manufacturing or research customers. While some might question the need for another space station or even multiple ones with different functions, Ondler is sure we need space stations both in the near and distant future.

“The immediate use of our space station hubs will be to experiment with and manufacture products in microgravity that cannot be manufactured on the ground,” he says. He cites some interesting, practical solutions that have been explored on the ISS:

- A fiber optics cable that has 100 to 1,000 times the transmission length capability of current fiber optics.

- Perfect retinal and corneal implants that can be bio-printed in microgravity but would deform if made on Earth due to gravitational forces.

- Metal alloys whose components would settle out like oil and vinegar on Earth but stay together in microgravity and create completely different metal characteristics and capabilities.

- Perfect protein crystals for faster and more efficient drug evaluations.

“And then there's a bigger, more existential need for space stations in the long run — pushing humanity beyond the Earth, “Ondler concludes. “It may be 100 or 1,000 years in the future, but to survive as a species we will have to populate multiple planets.”

New space stations will be the stepping stones to these planets. Ansys simulation solutions will be there to help engineers solve their toughest challenges.

Check out the Ansys Startup Program for more details on how your company can participate.