-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

January 03, 2018

Investigating Placement of Antennas Inside an Aircraft Fuselage

You may be surprised to learn that a standard passenger jet can have 30 to 50 antennas protruding from the aircraft’s external surface, producing drag forces that can drastically reduce fuel efficiency at a time when airlines are trying to reduce energy consumption. Most antenna designs are engineered for safety purposes, such as air traffic control, traffic collision avoidance, instrument landing systems and distance measuring equipment. Increasingly, antennas are being added to meet passenger demand for more and faster Wi-Fi access, in-flight TV and cellphone applications.

Antennas are mounted on the exterior of today's airliners

When the aircraft shell was made of aluminum, there was no choice but to place these antennas on the surface, because aluminum blocks the signal to or from the antenna. But now that tough, carbon-based composites are being used for many structural components of an aircraft, antenna design can be re-examined to determine whether it is possible to embed some antennas inside the fuselage to reduce drag while maintaining efficient operation. Optimized aircraft antennas demand omnidirectional transmission — equal radiation transmission in a spherical pattern with the antenna as the origin. When a plane is hurtling through the sky at hundreds of miles per hour, it is essential that signals can be transmitted and received from any direction, because missing a critical safety transmission due to a blocked path in one direction could lead to tragedy.

Simulation for Antenna Design

So engineers at the Brazilian National Institute of Telecommunications (Inatel) and Embraer have teamed up to determine whether antennas can be designed to work omnidirectionally while being located inside a composite-based fuselage. They have chosen Ansys HFSS electromagnetic simulation software to evaluate antenna operation when surrounded by various composites to determine if embedded aircraft antennas are feasible. Virtual design and testing using engineering simulation technologies have enabled them to consider hundreds of alternative antenna installation designs, a number that would be time- and cost-prohibitive using traditional build and test methods. They tested hundreds of possible configurations virtually using HFSS in the time it would have taken to build and test one physical prototype.

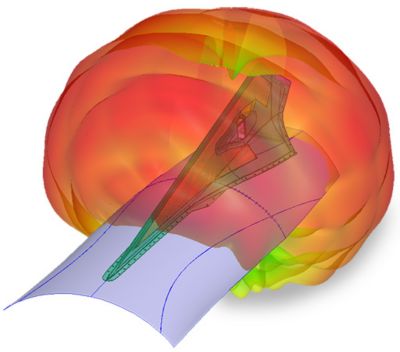

Ansys HFSS simulation results show radiation amplitude field generated by antenna designed within fuselage.

As the materials we use and the methods of manufacturing change in the aerospace industry (and virtually every other industry) leading companies are examining every design detail to, for example, increase efficiency, safety and output. This is only one instance of how simulation enables organizations to reliably develop new designs.

To learn what the engineers at Inatel and Embraer discovered about the possibilities of embedding antennas into aircraft fuselages to reduce drag and improve fuel efficiency while maintaining full communications capacity, read the article "Inside Story" in Ansys Advantage magazine.