-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

Ansys Blog

January 23, 2020

The Best Simulation Examples from 2019 & the Good They'll Do

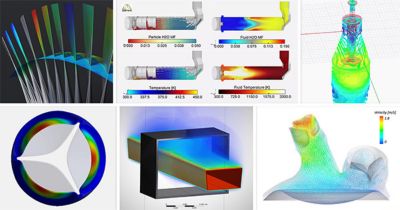

Every year the Ansys Hall of Fame (HoF) awards three academic and three commercial teams for their amazing simulation examples.

The Ansys Hall of Fame (HoF) winners

This year, organizations from nearly 20 countries sent in applications and there were 21% more applications sent than last year. After much deliberation, academic awards will be going to simulation examples that will save lives and commercial awards will be going to simulations that will save millions of dollars.

So, without further ado, here are the winners of the Ansys HoF.

The Best Academic Simulation Examples of 2019

University of Rome “Tor Vergata,” Italy

Engineers know that performing a computational fluid dynamics (CFD) simulation with moving wall boundaries is quite complex. However, this application is very important as it can simulate the mechanics of the heart and cardiovascular systems.

As a result, when Ubaldo Cella, a researcher from Tor Vergata, presented this simulation it won an Ansys HoF academic award.

Simulation of the cardiovascular system

(courtesy of University of Rome “Tor Vergata,” Italy)

Cella used Ansys Fluent, Ansys Mechanical and RBF Morph to simulate the moving walls and fluid–structure interactions of a cardiovascular system. These simulations were used to assess custom valves that are coupled to individual patient data. By bringing these simulations into the clinic, Cella will help doctors save lives.

Politecnico di Milano, Italy

Giulia Luraghi, a PhD engineer from Politecnico di Milano, also received an Ansys HoF academic award for work on cardiology. The engineer used Fluent and Ansys LS-DYNA to simulate the valves and blood flow associated with an artificial ventricle.

Simulation of the blood inside the left chamber of an artificial heart

(courtesy of Politecnico di Milano, Italy)

Luraghi’s computational model accurately reproduced the fluid dynamics of the blood inside the left chamber of an artificial heart. The simulation also displayed the displacement of the heart’s aortic and mitral valves. The results portrayed accurate motion of the valve leaflets and membrane.

King Abdullah University of Science and Technology, Saudi Arabia

Researchers from King Abdullah University of Science and Technology (consisting of Sebastian Celis and Li Zhang, graduate students, and Mohamed Farhat, Ph.D) won an academic Ansys HoF award for their landmine detection research. Landmines continue to be a danger to military personnel and civilians long after wars end. That is because conventional radar isn’t able to detect these weapons due to their plastic containers.

Simulation detects dielectric materials in plastic

(courtesy of King Abdullah University of Science and Technology, Saudi Arabia)

The researchers, however, were able to use Ansys HFSS and machine learning to detect plastic bottles filled with dielectric materials that mimic how explosives react to high frequencies. With this technology, the researchers can save countless lives around war torn areas.

The Best Commercial Simulation Examples of 2019

Druids Process Technology, Spain

Mario Gregorio Angeloni, a manager at Druids Process Technology, won an Ansys HoF commercial award for displaying the ability to detect small cavities in high temperature copper ingots. These cavities can cause significant production shutdowns for those that produce rods from the copper ingots.

Simulation detects copper ingot cavities

(courtesy of Druids Process Technology, Spain)

Angeloni developed an electromagnetic detector that finds copper ingot cavities. The detector was designed using:

- Ansys Maxwell to check the receive (Rx) coil’s configuration and induced current

- Ansys CFD to check the detector’s behavior under extreme temperatures

- Ansys Mechanical to determine the thermal and pressure effects on the electronics

After only a month of operation, Angeloni reports that the detector paid for itself.

Astec Inc., UK

Andrew Hobbs, an engineer from Astec got an Ansys commercial HoF award for his work on hot asphalt aggregate dryers. Traditionally, half of the energy input of these dryers goes into the phase change.

Simulation of the mass transfer between aggregate particles

(courtesy of Astec Inc., UK)

Hobbs thought he could do better. So, he developed software that captures the mass transfer between the aggregate particles. The software utilizes Fluent to assess the momentum and energy exchange between the fluid phase. With this tool, Astec designed an efficient dryer that produced various competitive advantages, like reducing costs and emissions.

NUM solutions, Czech Republic

Tomáš Peterka, an engineer from NUM solutions, also won a commercial Ansys HoF award for work on flutter. Flutter describes the self-excited vibrations that are caused by fluid-structure interactions in rotating machines. These vibrations can cause turbomachinery to experience blade loss, damage and failure.

Simulation predicts blade flutter

(courtesy of NUM solutions, Czech Republic)

Peterka developed the FLTR tool within Ansys CFX. It predicts blade flutter, reduces simulation time by 60% and pre- and post-processing time by 95%. This enabled NUM solutions’ customers to accelerate the development of flutter-free blades.

To learn more about these winners, visit the Ansys Hall of Fame.