-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

Ansys Blog

February 16, 2017

Ansys HFSS 18 – Raising the Bar in Electronics

Ansys HFSS users are constantly telling me, “Wow, I didn’t know HFSS could do that!” I guess I shouldn’t be surprised — our software development and product management teams have been working tirelessly over the last few years to integrate ever more valuable features into HFSS to deliver a product worthy of its well-deserved reputation as “the gold standard.” Focusing on automated simulation and design workflows for antennas and high speed electronics, Ansys HFSS 18 will help you achieve the increasing requirements for wireless connectivity, thermal performance and power efficiency within shorter design schedules.

Antenna Design

Antennas are often designed in isolation under ideal conditions. Look in any textbook on antenna design and you will see the equations and design procedures are developed with the antenna structure in “free-space” or on idealized platforms.

While this is appropriate for initial design studies, antennas are actually installed within an electronic product, mounted on a platform such as an aircraft or automobile, or placed in close proximity with other antennas.

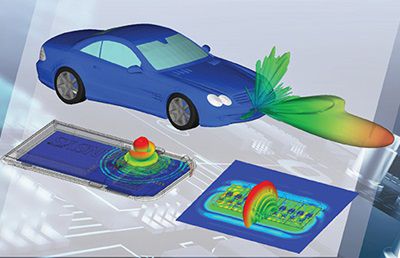

How an antenna is integrated into its environment impacts overall radio frequency (RF) system performance, and the simulation of the installed antenna performance can challenge most electromagnetic field simulation tools on the market.

Ansys HFSS 18 leverages new technology for simulating this installed antenna performance with the integration of Ansys HFSS SBR+ (shooting and bouncing ray) into the HFSS desktop. Using this powerful, efficient and accurate method, HFSS SBR+ reliably predicts performance of antennas mounted to electrically large platforms — problems previously considered too large to solve. Together with the integrated Antenna Design Toolkit, antennas synthesized, designed and optimized in HFSS can be integrated to their platform and rapidly solved with the HFSS SBR+ solver.

With a rapidly increasing number of wireless devices and a finite spectrum in which to operate, wireless systems are more likely to interfere with each other and degrade performance. This “RF co-site” problem involves not only the antenna coupling, but also how the associated radio is susceptible to RF interference from another radio, even when the interfering radio may be operating in a different frequency band. Thus, understanding RF co-site necessarily involves both the antennas and the RF systems to which they are attached. The Ansys 18 RF option now includes EMIT, a simulation tool for predicting RF co-site and EMI mitigation of multiple radio transmitters and receivers.

Broadband Adaptive Meshing

Ask six wireless experts “what is 5G?” and you might get ten different answers. All agree that 5G will provide much greater data rate to users, 1,000 times more bandwidth compared to 4G, the possibility to connect to billions of the Internet of Things (IoT) devices and a large reduction in energy use.

While the 5G standard is still in development, some requirements are known and should be considered when selecting simulation and design tools. In particular, in order for the mobile user to enjoy 10Gb/s speeds with low latency, electronics and wireless systems will need to be designed to provide very high instantaneous bandwidth, which in turn means that simulation tools need to deliver accurate and reliable broadband results.

HFSS users have always been able to mesh at multiple frequencies for confident broadband results, but Ansys HFSS 18 introduces even greater capability for broadband simulation of electronics, wireless systems, and antennas.

This new broadband adaptive meshing — or BAM — fully automates the ability of HFSS to efficiently and quickly refine the mesh across a device’s frequency spectrum. Now the user simply defines the frequency band of interest and HFSS automatically refines and optimizes the mesh using information across the entire frequency band. This enables you to deliver even more reliable broadband results faster with extreme confidence and reliability.

3D Components

As communication systems push the limits of component size, weight and performance, engineers must adopt new technologies and smarter workflows. Sharing accurate component design data among engineering groups is critical to developing complex, next-generation electronic devices.

Whether the component is part of an RFIC/MMIC, module, surface mount device for PCB design or a complete system, sharing high-fidelity model information that accounts for the EM field interactions between integrated components and system platforms enables design teams to quickly and safely adopt new technologies.

The 3D electromagnetic component in HFSS is a breakthrough in model sharing and design collaboration, allowing you to create HFSS-ready, 3D design components that can be easily shared between colleagues and collaborators and provide all the information to successfully simulate and design RF and microwave components into high-frequency networks.

In addition, a patent-pending encryption option is available which allows the component creator to password protect and hide critical detail from an end user which can further facilitate design collaboration and help our customers deliver more capable and reliable electronics products to market.

Multiphysics: Thermal Efficiency and Mechanical Reliability

Ansys provides a complete multiphysics flow to address electrical, thermal, and structural reliability in high-frequency systems. With smaller, lower power, more portable devices, the design of isolated components is no longer valid. You can’t work from a schematic abstract of a RF and microwave system; you must consider the physical description of the system so that all physical effects can be included. This means visualizing the entire physical design, inserting appropriate components such as surface mount devices, connectors, MMICs/RFICs, and running linear, nonlinear, and transient simulation with all electromagnetic effects included. Then you must perform comprehensive analyses including thermal, stress, shock, and vibration effects to capture all multiphysics effects.

To that end, we have developed a new integrated RF design flow to support high-frequency design from layout, inclusion of signal integrity, power integrity, EMI, 3D device integration and thermal and structural reliability; especially important for mission critical electronics found in transportation.

I could go on about the innovations available within Ansys HFSS 18, but the editors have cut me off! However, you can learn more from the HFSS hightlight page.