-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS BLOG

June 5, 2023

Airbus Helicopters Achieves Energy-Efficient, Safety-Critical Cockpit Designs with Ansys Simulation

Even pedestrians know how distracting the glare of the sun, lights from approaching vehicles, or reflections from rain can be. For drivers, optical distortions become even more challenging while trying to safely operate a vehicle on the road. In addition to exterior lighting conditions, drivers often face interior lighting challenges if important information on a vehicle’s indicator panels is not easily visible. Now consider how difficult a similar set of challenges is while piloting a helicopter at night or in difficult weather conditions, squinting toward the sky and control panels to navigate the best course of flight. Clearly, it would not be a safe situation for the pilot or any crew members and passengers on board.

Close-up of Airbus Helicopters’ H175 cockpit and instrument panel.

It’s quite clear that safety is a top priority in aviation and optical system design plays a pivotal role in that. In addition, as climate concerns have increased around the globe, sustainability has grown in importance as well. Regulatory agencies such as the Federal Aviation Administration (FAA) and European Union Aviation Safety Agency (EASA) require manufacturers to design safe, energy-efficient products. This heightened call for safety and efficiency has prompted many manufacturers to explore new solutions to improve design and accelerate certification.

Leading aircraft manufacturer Airbus Helicopters integrates Ansys’ simulation solutions to enhance pilot visibility and cockpit displays, while reducing power consumption, material waste, and related costs by implementing virtual testing and prototyping. By applying critical insight from Ansys Speos optical system design software, Airbus improves and streamlines cockpit design while upholding aviation regulation standards with efficiency and predictive accuracy.

Airbus Helicopters integrates Ansys Speos to design and validate cockpit optical systems.

Steering Clearer with Simulation

Airbus’ helicopters are in service in more than 150 countries and include rotary-wing aircraft solutions for government, military, and law enforcement and civil and parapublic uses, which include both the public and private sector. To ensure the safe operation of all its aircraft, Airbus adheres to the highest standards during development and uses simulation to inform designs with valuable insight.

Speos enables Airbus to evaluate human visibility during cockpit design and predict behavior in conditions that cause glare, reflections, and distortions. Using this data, Airbus engineers improve pilot visibility and the legibility of screen displays for crew members.

Ansys’ simulation has been pivotal in the cockpit visibility designs for a good number of Airbus helicopters, including the medium twin engine H160, super-medium twin engine H175, and heavy twin engine H225. For reference, each of these aircraft can house one or two pilots and up to 12, 18, and 19 passengers, respectively. Airbus designs military versions of nearly all of its aircraft, hence the H160M, H175M, and H225M are each based on a civilian model design, though pilot and crew capacity may vary.

Airbus Helicopters’ super-medium twin engine H175 can carry two pilots and up to 18 passengers.

Speos provides a user-friendly, intuitive set of features within a 3D platform. This helps engineers create designs from scratch or optimize current designs by seamlessly integrating layout and shapes directly into any computer-aided design (CAD) environment for realistic visualization.

“Analytical computations can sometimes be difficult to explain to crew members and certification authorities in relation to the effects of light within the cockpit, but it is necessary,” says Stephane Poveda, an engineer in the Human Factors and Human Machine Interface department at Airbus Helicopters. “With Ansys Speos, we can verify potential effects and then show them to team members and authorities using realistic, visual renderings and simulations. This is hugely beneficial during the design and certification of each helicopter, particularly in explaining varying lighting conditions within the cockpit that shift from day to night and through different weather.”

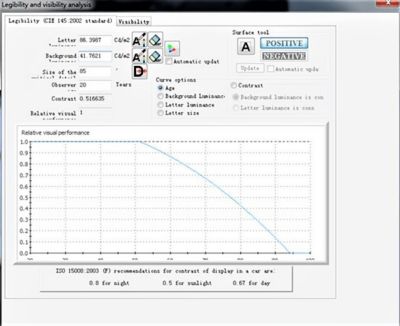

One of the most beneficial features in Speos is its human vision component. Through this capability, designers can determine visual aspects such as reflection, visibility, and legibility according to the individual human observer. With this insight, designers can create safer lighting conditions for pilots and crew members. Through a refined human eye sensor model, Speos provides access to human vision algorithms for luminance and immersive 360-degree observer results. Using physiological human vision modeling, designers can improve the quality that is visually perceived on displays by optimizing colors, contrasts, harmony, light uniformity, and intensity while also considering ambient lighting conditions, including day and night vision.

Ansys Speos uses refined human eye sensor models to simulate luminance and provide immersive 360-degree observer results.

Boosting Efficiency with Simulation-Driven Design

Another beneficial feature within Speos is its extensive optical library, which includes more than 4,200 samples of lights and materials. With the support of this online database, Airbus selects more efficient and suitable materials for each design. Additionally, with Speos’ lighting system analyzer tool, engineers can ensure their selections match design requirements and verify compliance with industry or legal standards.

“Advanced optical design software tools like Speos are extremely helpful for Airbus to design and optimize optical systems for its helicopters,” says Fabien Bastide, a manager in application engineering at Ansys. “The utilization of optimized equipment, improved material selection, and advanced technology adds significant value to the aircraft manufacturing process.”

In addition, optimized equipment and material selection allows manufacturers to adhere to weight and performance compliance requirements more easily, which accelerates the certification process. Similarly, Ansys’ optical system design analyses enable engineers to model the behavior of new recyclable material and update old technologies, such as replacing previous lighting with advanced LEDs to reduce power consumption.

“These tools enable engineers to consider various factors such as field of view, resolution, and image quality, and simulate system performance under different lighting conditions and environmental factors,” Bastide adds. “As a result, manufacturers gain valuable insights into potential issues and can make informed design decisions.”

By improving material selection and embracing more virtual testing and prototyping, Airbus is able to reduce material waste while decreasing the time, energy, and costs associated with physical testing and prototyping. Further, with Speos graphics processing unit (GPU) computation, Speos delivers significant improvements to simulation performance, including benchmarks between 140-260 times faster on average, without compromising accuracy.

Ansys Speos includes legibility and visibility analysis tools that enable designers to improve optical systems based on human vision perception.

Improving the Future Sights of Flight

As members of the aviation industry strive to meet consumer demands, safety regulations, and global sustainability initiatives, manufacturers are embracing digital transformation more frequently and integrating simulation earlier in development to inform design. With the help of Speos, manufacturers such as Airbus continue to improve safety-critical cockpit designs while meeting industry expectations.

To explore Speos, register for a free trial today!