-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

Ansys Blog

November 10, 2020

Additive Manufacturing Meets Supply Chain Challenges Created by COVID-19

The strength of additive manufacturing has been on display during the pandemic while supply chain logistics snarled and traditional manufacturing stalled. Shortages of critical personal protection equipment (PPE), medical devices and testing accessories affected regions the world over. It seems like the perfect problem for digital design and 3D printing to solve with on-demand manufacturing.

"This crisis has really shown the need for rapid, customer-focused manufacturing," says Edward D. Herderick, Director of Additive Manufacturing at the Center for Design and Manufacturing Excellence, The Ohio State University. "Outsourcing to Asia with long supply chain lead times is not nimble enough to respond in a crisis. It has really demonstrated the need for truly digital, truly rapid manufacturing. Additive manufacturing is definitely the poster child for this development and its integration into the software and digital ecosystem is a powerful tool."

On-Demand Manufacturing in Demand

Only the most prescient government and healthcare organizations would have seen the need for additive manufacturing as part of their crisis management plans. As a result, there was a scramble in the early stages of the pandemic to identify what emergency equipment could be 3D printed, who could produce those products and how to get them to those in need.

In the U.S., some states turned to universities to develop a plan. In Kentucky, for instance, the state government asked universities to use their resources to design and implement manufacturing processes for face shields, masks, gowns, ventilators, ventilator components and even test swabs. The University of Louisville’s Additive Manufacturing Institute of Science and Technology (AMIST) took up the challenge to develop manufacturing models that could be used by small businesses and other regional manufacturing resources.

“Over 60,000 face shields and 25,000 nasal test swabs were directly supplied through the efforts at the UofL AMIST,” says Timothy Gornet, AMIST Core Manager.

Those efforts included meeting initial face shield needs via additive manufacturing for the frames and laser cutting for the actual shield material. Nasal test swabs were designed and simulated for additive manufacturing. As the need increased exponentially, the AMIST partnered with manufacturers like Samtec and GE Appliances, as well as maker spaces like Maker13 to transition face shield production to higher throughput injection molding tools.

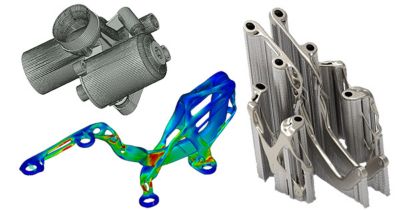

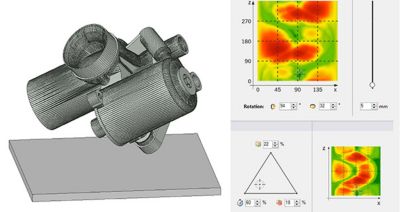

Intuitive orientation optimization for metal additive manufacturing

is possible using the heat maps in Ansys Additive Solutions.

The experience at the University of Louisville and other universities shows on-demand manufacturing's potential as a stop-gap for global supply chain shortages. It also exposed some of its current weaknesses, namely speed, scalability and coordination.

"Although the process is slow, additive manufacturing has demonstrated that it can be used to fill short-term shortages of PPEs by leveraging the many 3D printers available in the community," says Albert To, William Kepler Whiteford Professor, University of Pittsburgh. However, on-demand manufacturing isn't immune to supply chain disruptions. "We also saw that there was a shortage of 3D printing supplies, such as plastic filaments."

Extend the Digital Thread to Meet Supply Chain Challenges

Of course, even more widespread adoption of additive manufacturing would decentralize suppliers, thus creating a larger supplier base, says Asim Tewari, Ph.D. and G.K.Devarajulu Chair Professor in the Department of Mechanical Engineering, IIT Bombay, India. "It will also promote the interchangeability of suppliers due to the nature of additive manufacturing technology. This will reduce dependencies on the current supply chain infrastructure," he says.

For suppliers to be interchangeable, as Tewari says, would require them to have the same source files to 3D print during an emergency. That would require coordination at a high level.

"If there were printable designs of consumable medical and safety devices as a reserve through a national registry, it could provide the opportunity for small communities and underserved areas to leverage local additive manufacturing technologies to produce the products and gap fill as needed locally," says Gornet. "The digital thread data can be easily shared and replicated globally using additive manufacturing."

Other lessons learned by Gornet during the pandemic include the need to:

- identify medical and emergency consumable parts and emergency devices for various pandemic or disaster response situations

- work with government agencies for pre-approvals of emergency designs

- develop a regional network and strategies for enlisting small manufacturing resources to supplement the supply chain

- develop a portfolio of materials to meet emergency, on-demand manufacturing

David W. Rosen, a Professor at the Georgia Institute of Technology, says additive manufacturing can also supplement supply chain gaps by enabling more traditional just-in-time manufacturing via rapid tooling production.

"The time, effort and cost savings associated with designing and fabricating tooling can be significant," he says. "If lead times for tooling are weeks or months, then the capability of fabricating parts within hours or days could have huge consequences for many applications or circumstances where fast response is required. This could be in a fast-changing marketplace or in a pandemic or other disruptive event."

Herderick agrees. "Additive manufacturing feeds the fundamental principles of lean manufacturing, tightening the feedback loops between customers, manufacturers and other stakeholders," he says. "Additive manufacturing is driving a virtuous cycle of better design and rapid delivery that improves product development."

A global pandemic is a tough test for any technology, but additive manufacturing has proved its worth. The on-demand, customizable, decentralization benefits of 3D printing may receive renewed interest in the coming months and years. The lessons learned from COVID-19 could have far-reaching effects on how Industry 4.0 supply chains develop, whether 3D printers become a more critical part of the Industrial Internet of Things (IIoT) and how governments, academia and private institutions collaborate on localized manufacturing.

"This event, although still not over, has proven that in areas where there is a shortage of life-altering consumables, that additive manufacturing can address an immediate need,” says Gornet. “Strategies can be developed to leverage community action and small business to meet short-term demand until the supply chain is able to catch up."

Request an Additive Suite demo

Q&A: The Role of Educators in Additive Manufacturing Adoption

How can universities and training bodies best assist industry in ensuring the next, and current, generation of supply chain experts are well versed in the benefits, drawbacks and implementation of additive manufacturing technology? We asked five educators.

Tim Gornet, University of Louisville: "Universities — through collaboration among medical, engineering and various other schools — have the capability to develop emergency preparedness plans to address future disruption in health and quality of life issues based on compromised supply chain from national disasters, pandemics and other broad disruptions."

Tim Gornet, University of Louisville

Asim Tewari, ITT Bombay

Asim Tewari, IIT Bombay: "Universities can play a significant role in educating the supply chain experts about the emerging possibilities in having a global supply chain using additive manufacturing. However, the businesses will find it challenging to deal with the three biggest drawbacks of additive manufacturing: cost, inability to produce large volumes and the lack of microstructural control to provide the desired properties. Hence, it is expected that, in the beginning, additive manufacturing will find inroads only in specific niche products."

David W. Rosen, Georgia Institute of Technology: "Clearly, a need exists for education and training on additive manufacturing. The training and certification programs offered by ASTM International and SME are a good start. Other credentialing, and micro-credentialing, programs are under development and should help to raise the profile of additive manufacturing. Universities should offer a variety of formal and informal education opportunities for students.

David W. Rosen,

Georgia Institute of Technology

"Having a maker space that includes additive manufacturing equipment is an outstanding opportunity for much informal learning about additive manufacturing, maker culture and design thinking, as well as for getting trained on a variety of different types of equipment."

Albert To, University of Pittsburgh

Albert To, University of Pittsburgh: "Universities can best assist industry by creating certification/degree programs in additive manufacturing, as well as forming consortia to engage industry to learn the latest about additive manufacturing technology."

Edward D. Herderick, The Ohio State University: "The way we think about it at OSU CDME (Center for Design and Manufacturing Excellence) is all about growing the ecosystem locally and globally. The foundation has to be hands-on experience with the latest equipment that grounds the students coupled with a growth mindset of 'what if.'"

Edward D. Herderick,

The Ohio State University