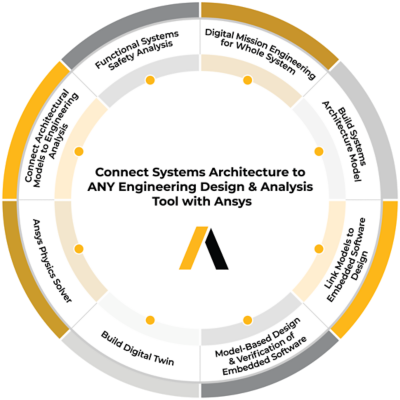

Model-Based Systems Engineering Features

The combination of technologies and open ecosystem infrastructure mindset make Ansys the best partner for MBSE.

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

By aligning people, processes, and technology around a single vision of a product, Model-Based Systems Engineering promises to dramatically reduce the development cost and risk of complex systems for hardware and software.

As products across multiple industries, such as automotive, aerospace and defense, and high-tech, become more complex, there’s a need to manage complexity, get products to market faster, and maintain safety and security. Ansys has the technology that allows customers to implement MBSE which stems from the core strength of engineering simulation. Supporting an iterative process, MBSE manages requirements, enables collaboration, ensures traceability, and supports the entire lifecycle development.

The combination of technologies and open ecosystem infrastructure mindset make Ansys the best partner for MBSE.

Connecting the System Architecture Model (SAM) with virtually any analysis or workflow, assuring the product vision remains in sync with the underlying analysis throughout the product lifecycle. Using the latest SysML V2 modeling language.

Every successful MBSE implementation requires the integration of tools from many different vendors into a cohesive whole. Ansys has an open ecosystem architecture to enable this.

Through systems analysis, requirements can be validated and verified, especially early in the design process, resulting in less rework.

Design, verify and automatically generate code for critical embedded software embedded within a system. Helping to secure your certification journey.

“As a company, we are seeing the kind of returns that people are talking about… we can count in the millions of dollars the bookable savings we've been able to come across just in a few limited applications.“

— Robert Wirthlin, Ford Motor Company

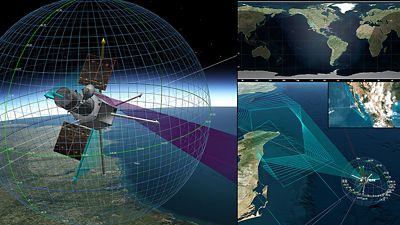

“Automating and integrating the simulation into this system model allows the team to rapidly identify potential issues with changes to mission requirements, as well as perform continuous verification of requirements and mission design parameters throughout the lifecycle of the spacecraft... The overall improvement versus the original process was about a 7X speedup in turnaround time.”

-- Phathom Athena Donald; Systems Engineer / Lockheed Martin Space

“Ansys medini analyze helped us to provide functional safety analysis for hardware, software and systems based on and fully compliant to architecture models.”

— Günter Gäbelein, Safety Assessor / ZF Friedrichshafen AG

엔지니어링 과제에 직면하고 있다면우리 팀이 도와드리겠습니다. 풍부한 경험과 혁신에 대한 헌신을 가지고 있는 우리에게 연락해 주십시오. 협력을 통해 엔지니어링 문제를 성장과 성공의 기회로 바꾸십시오. 지금 문의하기