-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

-

Ansys는 학생들에게 시뮬레이션 엔지니어링 소프트웨어를 무료로 제공함으로써 오늘날의 학생들의 성장을 지속적으로 지원하고 있습니다.

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

What’s in a Name? When Polymers Are More Than Just “Plastic”

Daniel Carmine Manocchio Material Technology Manager Kärcher

Winnenden, Germany

Accurate information about materials is part of the foundation for high-quality, reliable products. But with naming conventions between different suppliers often inconsistent or incomplete, that’s the kind of question manufacturers grapple with every day.

WILL A MATERIAL BY ANY OTHER NAME STILL WORK AS WELL?

The problem is even more complicated for buyers of plastics; despite the industry’s standardization efforts, similarly named grades from multiple polymer suppliers can have completely different material properties. This creates costly and time-consuming disruptions to the development process, including requiring additional testing. Yet without those tests, it becomes impossible to specify exact grades on R&D drawings, ensure that parts and products meet ISO and other standards, and comply with regulations.

For a small company, the issue is serious enough. But when your business involves approving and purchasing polymers from more than 100 materials suppliers, used in making 3,000 products, validating and managing materials properties data can be a convoluted and potentially unwieldy process.

That is why Kärcher, the market-leading manufacturer of residential and industrial cleaning equipment, uses Ansys GRANTA MI to consolidate and manage information about materials, as well as to store test data for materials and finished parts. The software, available within Ansys Mechanical and Ansys Electronics Desktop, provides easy, clickable access to materials property data and is most commonly used for design and simulation.

Beginning with 1.5 million data points, Kärcher’s materials engineers used GRANTA MI to build comprehensive records about every polymer grade the company buys for 20 facilities worldwide. This has enabled them to compare and substitute materials more efficiently while reducing unnecessary or superfluous testing. Altogether, better materials intelligence has made Kärcher more agile, further solidifying its market position.

FIFTY SHADES OF YELLOW

All the factors that make a brand stand out rely on the right materials, batch after consistent batch. In Kärcher’s case, that includes the distinctive yellow hue of its equipment.

The suppliers who provide Kärcher’s polymeric components can either buy the materials already tinted or can dye them before injection molding by adding color concentrate, a so-called masterbatch.Information about how the polymer was colored is usually represented by a code, but that detail is often left off material data sheets. Failure to provide the exact grade name can affect certification of the final part, and that can be a time-consuming and expensive problem to fix.

The “K7” consumer class is a high-pressure cleaner with a water-cooled motor.

Kärcher uses Ansys Granta MI to store data from dynamic mechanical analysis. Lab equipment bends the sample with a high-frequency cycle while temperature changes from -100 to 100 degrees C.

In the U.S., for example, the materials used in the electrical appliances Kärcher manufactures must be UL-listed, meaning they meet specifically designed requirements. Conforming to UL is no easy task, especially because the rules are stringent and complex. In some cases, UL listings are valid only if the polymer is colored by the original material producer. When a natural-colored polymer has been dyed with a masterbatch, its UL listing persists only if the masterbatch is also UL-listed for that polymer. Incomplete data sheets make it extremely difficult for Kärcher to conform to UL requirements without product certification tests that can delay time to market.

To overcome this issue, Kärcher engineers are storing UL listing information in each material record in GRANTA MI and linking records to one another. But that is not the only color-related data they are maintaining.

GRANTA MI has also given them a way to benchmark approved colors from multiple suppliers and ensure precise color-matching. By storing the color measurements for color chips, test samples and final parts in the test records, then feeding that information into the material records, Kärcher teams can quickly determine if a color is matched correctly or not, and avoid winding up with 50 shades of yellow.

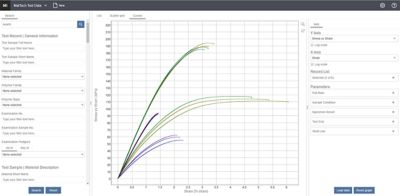

Stress versus strain curves from tensile testing under different conditions, presented in Ansys Granta MI Explore.

TIME SPENT UPFRONT SAVES HUNDREDS OF HOURS

Color information represents just a fraction of the 35 GB of data Kärcher stores in GRANTA MI. The company’s database incorporates comprehensive material properties information, including tensile testing, hardness test results, elastomer testing, chemical analyses regarding hazardous substances, and more, and everything is interconnected and easily accessible. Among other benefits, this has provided a sound framework for better, faster failure analysis; access to proper material definitions and all former examination reports saves Kärcher approximately 10% to 15% per case.

Implementing GRANTA MI was surprisingly efficient and straightforward, thanks to Ansys consulting, extremely deep training and the software’s broad range of features. That’s not to say the process wasn’t time-consuming, however: It took roughly 250 person-days to build up the database and migrate 20 years’ worth of legacy data into the system. But considering that the company’s nine materials engineers and 400-member R&D staff are now saving the equivalent of at least 600 person-days per year searching for information — and are equipped to spend less time solving problems — those were hours well spent.

Fortunately, a year after installing GRANTA MI, Kärcher implemented Jira as a digitalization tool for internal workflows. This enabled the company to end paper ordering and begin semi-automated data entry. Interconnecting the lab, GRANTA MI and Jira means engineers can handle examination data and reports with little effort. In addition, there is greater consistency across the organization, and the risk of providing the wrong data by mistake is reduced to near zero. Results of tensile testing and chemical analyses regarding hazardous substances are automatically processed by an Excel script and then uploaded to GRANTA MI, while results of color measurements, aging experiments and information about retained samples are entered manually in script-assisted Excel templates.

A SIMPLE, SCALABLE SOLUTION

In the two years since it was implemented in what might be described as an off-label application for a simulation product, GRANTA MI has proven to be a simple and scalable way for Kärcher engineers to manage materials properties data. Adding attributes and functionality is easy, and data can be structured according to users’ needs. Kärcher’s materials lab performs approximately 1,000 material examinations each year, and everything from the orders for testing to the data to the final report is now housed in one easily accessible location.

With Ansys GRANTA MI, Kärcher engineers have insight into everything materials related. And now they know exactly what is in each and every material, regardless of its name.

시작하기

엔지니어링 과제에 직면하고 있다면우리 팀이 도와드리겠습니다. 풍부한 경험과 혁신에 대한 헌신을 가지고 있는 우리에게 연락해 주십시오. 협력을 통해 엔지니어링 문제를 성장과 성공의 기회로 바꾸십시오. 지금 문의하기