-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

什么是跌落测试?

跌落测试是一种受控试用验,旨在研究产品从特定高度和方向跌落到硬表面上时发生的情况。每次测试后,工程师都会测量冲击大小、对功能的影响以及任何外观损伤。他们使用这些信息来改进设计或确定当前结构是否可行。

大多数人都熟悉对手机等消费类电子产品的测试,但除此之外,工程师在航空航天、消费品、重型机械、医疗设备甚至核材料运输等众多行业都会采用跌落测试。

任何跌落测试的目标都是确保产品和包装设计能够承受合理次数的跌落,并保证安全性、正常运行且不会造成外观损伤。除了物理测试之外,大多数公司还会在设计流程的早期阶段使用仿真进行虚拟跌落测试,以降低成本。

跌落测试主要研究产品在两个方面可能发生的损坏。第一个方面是在使用前的运输和存储过程中,第二个方面是在设备使用过程中。在使用前阶段,产品通常有某种类型的包装,因此需要进行包装跌落测试,以评估包装的耐用性。然后再对产品本身进行测试,以了解在最终用户那里的使用过程中的意外跌落时会发生什么情况。

有效跌落测试指南

进行有效且信息丰富的跌落测试的关键在于,建立符合行业标准的跌落测试程序,为设计团队提供有用信息,并对包装和产品设计进行验证。

跌落测试目标

任何跌落测试项目的第一步,都是确定测试的目标和对象。有时,唯一的测试目标就是满足FedEx等托运商或Amazon、Sam's Club等分销商所要求的标准。在另一些情况下,设计团队需要使用测试数据来优化产品或包装设计。目标应被清晰记录,并用于制定测试计划。

跌落测试中使用的变量

产品可以从无数个高度、多种不同的方向和多种环境条件下跌落,这些都是可由标准或设计团队定义的变量。有效的跌落测试应对以下变量进行明确定义:

- 跌落高度:重力会加速物体自由下落,因此跌落的高度决定了测试样本撞击冲击表面时的速度,也决定了冲击能量。

- 产品方向:当物体落在角落或边缘时,物体上的载荷会集中,与落在较大、平坦表面上相比,损伤程度更大。这就是跌落测试包括多个方向的原因。

- 跌落次数:产品或包装可能可以承受一次或两次跌落,但每次受到冲击后,都会造成额外的损伤。关于物体在不同高度下必须承受的跌落次数,许多测试都有相关规范。

- 冲击表面材料:跌落测试用的平面的材料特性会显著影响传递到跌落物体的能量。一些常见的跌落测试表面,包括:混凝土、抛光混凝土、钢、混凝土上的胶合板和混凝土上的乙烯瓷砖。

- 温度和湿度:测试环境中的温度和湿度是一个重要变量,尤其是对于纸板包装而言。这两个变量会影响产品、包装和跌落表面的材料属性。

跌落测试标准

跌落测试有多种标准,有些是由行业制定的,有些是由运输或分销产品的公司制定的,还有一些是由国际标准组织制定的。其中一些最常见的标准包括:

- ASTM D5276:通过自由落体对装载容器进行跌落测试的标准测试方法

- ASTM D7386:单一包裹输送系统包装性能测试的标准实践

- ISTA 3A:包裹输送系统运输,重量小于150磅(70kg)

- ISO 2248:跌落垂直冲击测试

- IEC 60068-2-31:测试-测试Ec:粗暴搬运冲击,主要用于设备型物品

- MIL-STD-810G 516.6:环境工程考量和实验室测试:测试:冲击

跌落测试设备

垂直跌落测试通常使用一套小型测试设备来进行测试并测量结果。测试规划人员应指定能够处理测试物体的尺寸和质量、准确测量测试的输入变量,并从测试中捕获所需数据的设备。

跌落测试仪

跌落测试仪可用于按照所需的高度、方向和冲击表面参数,对测试物体进行重复一致的跌落测试。其由一个冲击表面和一个机械装置组成,该装置可在所需高度和方向固定和释放测试物体。大多数机器都能自动提升和释放测试样本。

旋转滚筒跌落测试仪

小型电子组件和设备(如手机)可使用旋转滚筒跌落测试机进行测试。将测试物体放入旋转的滚筒中,滚筒会反复提升和跌落测试物体。许多公司使用这种类型的设备,来验证每种可能的跌落方向都已经过测试。

加速度传感器

加速度是工程师需要的关键信息之一,可帮助他们了解产品在冲击事件中承受的载荷。测试人员使用加速度传感器来测量包装中和产品关键位置的加速度。

光学检查器

工程师还需要了解测试物体在冲击后的外观损伤和物理变形。技术人员可以使用各种校准测量设备进行视觉检查,用高质量摄像头或光学光扫描来获得变形表面,从而实现上述目标。

产品测试夹具

测试夹具,可在涉及产品功能测试时用于自动化功能测试。

跌落测试的典型步骤

- 规划:测试工程师利用目标、产品规范以及行业或公司标准来规划一组最有效的测试,以满足所有要求。

- 设备校准和设置:跌落测试设备应针对测试进行校准和配置。这包括解决安全问题,并在需要时实施自动化和数据采集。

- 样本准备:然后,技术人员必须准备测试物体本身。这可能是包装和产品的原型,也可能是从生产中抽取的测试样本。同时,还需要安装加速度传感器,并根据需要应用标记。此阶段还应对质量进行验证。

- 执行:使用跌落测试规划中所述的测试设备进行测试。执行中的每个步骤都要保持一致并遵循测试计划,这一点非常重要。

- 检查和分析:每次跌落测试后,技术人员和工程师都会检查测试物体,并捕获任何几何结构、外观或功能上的变化。同时,还会对结果进行分析,以获得测试或工程团队所需的数据。

- 文档和报告:任何测试计划都需输出一份完整而详细的报告,其中包括已完成的操作、获得的数据以及测试计划的任何例外情况。

跌落测试的五大优势

在开发新产品时,工程团队会重点关注其在正常操作过程中的功能状况。上述正常操作过程,包括在整个产品生命周期中的不同阶段将设备跌落。由于各种原因,跌落测试已成为产品质量的关键部分,其中包括:

1.安全性

验证产品安全性,是跌落测试最重要的目的。如果产品在跌落后结构完整性受损,则可能会泄漏化学品、过热、着火或以可能造成损害的方式运行。设计团队利用跌落测试或跌落测试仿真来优化产品及其包装的材料和结构,以满足安全规范。

2.产品耐用性和功能性

在满足安全要求后,跌落测试的下一个目标是验证产品在跌落后是否足够耐用,以保证其正常运行。这要根据所测试的具体产品进行判断。比如,IoT传感器可能会出现凹陷和刮擦,但只要它能继续收集准确的数据,就会被认为是功能正常的。

在医疗和国防行业中,功能性变得至关重要,因为产品功能的损失可能会对患者和作战人员产生重大影响。跌落测试可帮助设计团队验证其设计在合理的跌落次数下的耐用性。

3.客户满意度

产品跌落后的状态会对客户对产品和品牌的感受产生重大影响,尤其是在发生功能性减弱的情况时。此外,交付时包装的外观状态或产品本身在跌落后的外观,也会对客户满意度产生重大影响。凹陷、刮擦和裂纹可能不会影响功能,但确实会对客户对产品的印象产生负面影响。

跌落测试不仅可以避免相关损伤,还可以帮助设计团队与市场营销和客户支持团队合作,以明确最终用户关于产品可承受跌落范围的预期。

4.尺寸、材料、运输和存储成本降低

使产品能够承受从各种高度自由跌落的一个简单方法,就是增加包装和产品本身的材料。然而,这会增加材料、运输和存储成本,从而增加产品的整体成本。跌落测试可帮助工程师验证,其包装和产品设计是否能在满足跌落要求的同时,最大限度地降低成本。

5.更换、维修和保修成本降低

如果产品在运输或使用过程中受损,更换成本可能会迅速增加。跌落测试有助于确定哪些跌落类型在保修范围内,以及对托运人的要求。此外,跌落测试还可以提高产品的耐用性和包装质量,以降低与跌落损坏相关的潜在成本。

虚拟跌落测试仿真

物理跌落测试是质量保证中一个成熟且有效的方法,但物理测试只能在产品包装设计和可测试版本完成之后才能进行。此外,物理测试不仅成本高昂而且极为耗时,更不用说在研发流程后期更改设计的成本了。这就是许多公司使用仿真来进行虚拟跌落测试的原因,将其作为产品设计流程的一部分,而不是流程完成后的一个步骤。

Ansys LS-DYNA®软件是大多数行业进行跌落测试仿真的标准仿真工具。这是一个有限元分析(FEA)平台,可在时域中求解,并考虑质量、动量、复杂材料和复杂接触条件,这正是工程师进行跌落测试仿真时所需要的。仿真不仅可以帮助工程师了解其产品及其包装的跌落行为,而且还可以快速开展参数化“假设”研究,以推动这些设计。

仿真的另一个优势是,工程师可以看到包装或产品内部,并查看冲击事件中随时间变化的内部行为,从而提供比物理测试更深入的洞察。使用仿真进行跌落测试的工程师,可以获得装配体中任何位置的加速度、应力、变形、接触力、塑性变形和位移信息。

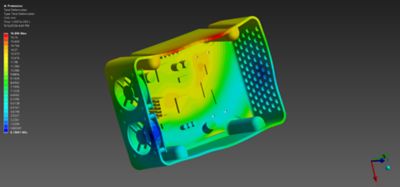

使用Ansys LS-DYNA对电子产品外壳进行跌落测试仿真,展示了其撞击刚性地板时的变形。

使用仿真进行虚拟跌落测试时,工程师应考虑以下最佳实践:

- 在可能的情况下,使用六面体(hex)单元创建高质量、精确的网格,确保厚度方向上分布有足够的单元,并在需要时使用高阶单元。相对均匀的单元尺寸也是关键。Ansys产品中有各种网格划分工具可以帮助完成此过程。

- 使用绑定接触来连接产品中彼此相连的组件,并使用摩擦接触来表示在冲击事件中可能相对于彼此滑动的表面。LS-DYNA软件中有大量工具可用于建立和管理接触连接。

- 利用LS-DYNA软件各新版本中添加的新功能。多case建模、纸板材料和新网格划分工具等功能,可改进跌落测试的功能和用户体验。

- 在您自己的硬件上或在云端利用高性能计算(HPC)。LS-DYNA软件支持多核并行处理,从而实现更大规模的模型和更短的求解时间。

跌落测试的未来趋势

客户和分销合作伙伴的期望在不断变化,从而推动跌落测试的技术和相关期望向前发展。此外,可持续性也对产品使用的材料及其包装方式产生了重大影响。

工程师在规划未来的跌落测试工作时,应考虑以下五种趋势。

可持续性

可持续性正在推动产品包装系统发生巨大的转变。在某些情况下,消费者和零售合作伙伴都期望能够使用产品本身的包装进行运输,而无需任何保护性包装。环境问题也促使产品及其包装使用更具可持续性的材料,并在整体上减少材料的使用。

成本降低

制造、包装和运输的成本可能相当高,因此企业在不断寻找降低成本的方法。跌落测试(尤其是跌落测试仿真)将发挥更重要的作用,帮助工程师进行设计更改,以降低产品及其包装的成本,同时确保耐冲击性能符合规范。

用户期望提高

用户对包装外观的要求在不断提高,并对产品能够承受的跌落高度提出了更高要求。在设计流程的早期阶段,工程师需要使用仿真跌落测试来满足这些期望,并赋予其产品竞争优势。

货架吸引力和开箱体验

另一个用户期望不断增长的方面,是产品在物理和虚拟货架上的外观,以及开箱体验。这些美学考量因素,将对冲击耐久性的设计特性产生越来越大的影响。在这方面,仿真跌落测试也能为工程师提供所需的工具,以便在研发周期早期尝试更多美观的包装设计。

多物理场仿真

在仿真领域,人们大力推动充分利用LS-DYNA软件等工具中的多物理场功能,并将其与Ansys Mechanical™软件、Ansys Sherlock™工具、Ansys Icepak®软件和Ansys Fluent®应用耦合。这样,便可以评估跌落产生的载荷和变形如何影响产品的性能和可靠性。

相关资源

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。