Case Study

-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

“With NVIDIA DGX and Ansys Fluent software, we are able to reduce the runtimes of our internal drive flow models from hours to minutes, approximately a 50 times improvement.”

— Kent Forbord, Senior Director of Advanced Mechanical Development, Seagate

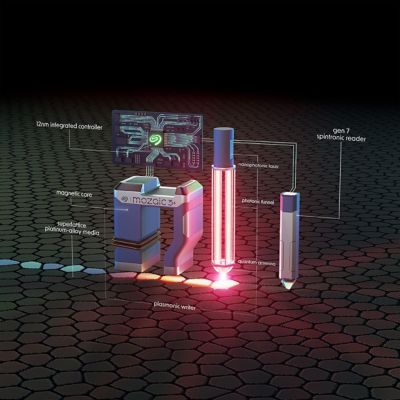

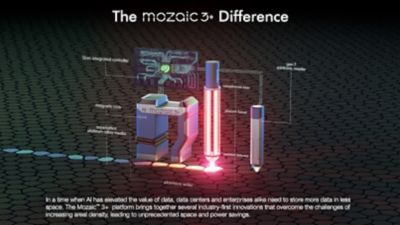

As artificial intelligence (AI) becomes more prevalent across industries around the world, the need for greater data storage is rapidly increasing. To meet demands sustainably, Seagate Technology, a leader in mass-capacity data storage solutions, uses Ansys simulation and NVIDIA graphics processing unit (GPU) hardware to develop its Mozaic hard drive technology, which stores data at previously unachievable levels without increasing power consumption.

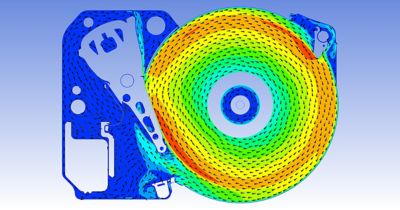

A computational fluid dynamics (CFD) simulation of a hard drive’s internal flow velocity in the Ansys Fluent platform. Image: Seagate Technology.

Challenges

Although adding disks to a hard drive increases storage capacity, it also increases material usage and power consumption. Alternatively, increasing areal density — the storage capacity per square inch of an object’s surface — enables each disk to hold greater data without using more material or disks.

Exos Mozaic 3+ hard drives hold up to 32 terabytes (TB) of data.

Forthcoming Seagate hard drive models Mozaic 4+ and Mozaic 5+ will be able to store 4 TB and 5 TB of data per disk, respectively.

Seagate’s previous workstation for computational fluid dynamics (CFD) studies to identify optimal designs for greater storage capacity was comprised of 40-core CPUs. Seagate’s CPU-based runtimes were approximately one month for chassis-level aeroacoustics models with a mesh size of about 50 million cells, while finer, higher-quality mesh containing up to 100 million cells took even longer. This was a cumbersome and time-consuming workflow that had to be changed.

Engineering Solutions

By integrating Ansys Fluent fluid simulation software and NVIDIA’s accelerated compute power via an NVIDIA DGX system, Seagate reduced the runtimes of their internal drive flow models from hours to minutes, resulting in a 50X improvement.

To increase track densities, Seagate uses Fluent software to optimize key airflow metrics in the drive, such as particle transport, windage drag, and structure excitation. At the system level, engineers perform thermal analyses to model the dynamic excitation on the outside of the drive, temperature, and pressure drop to assess cooling flow throughout the system. The team also performs aeroacoustics simulation to improve system chassis and fan designs.

Running these studies on Fluent software’s native multi-GPU solver, enabled by NVIDIA GPUs, enabled Seagate to greatly reduce their overall runtimes. This helped them meet their goal of reduced prototyping and physical testing, which ultimately led to shorter design cycles.

Seagate’s current Mozaic platform, Mozaic 3+, features areal densities of 3 TB per platter. Anticipated models Mozaic 4+ and Mozaic 5+ will store 4 TB and 5 TB of data per platter, respectively.

Benefits

- Seagate reduces the runtimes of its internal drive flow models from hours to minutes — approximately a 50X improvement — and reduces external aeroacoustics model runtimes from one month to less than one day.

- With reduced solve times, Seagate evaluates more designs in a shorter time and achieves a more optimal design.

- Seagate reduces prototyping and physical testing through more upfront modeling and design optimization, which helps shorten the design cycle.

- Ansys and NVIDIA technologies enable Seagate to streamline the innovation process and speed up time to market.

Designed with the most advanced materials and structures, Seagate’s Mozaic drives enable data centers to store more data in less space more efficiently.

现在就开始行动吧!

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。