快速规格

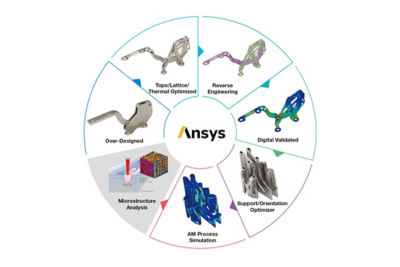

Ansys Additive Suite是一款综合全面的工作流程解决方案,能够为设计人员、工程师和分析师提供所需的关键洞察力。从增材制造(DfAM)设计到验证、打印设计等,该解决方案涵盖整个工作流程,有助于避免制造故障并交付设计准确的部件。

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

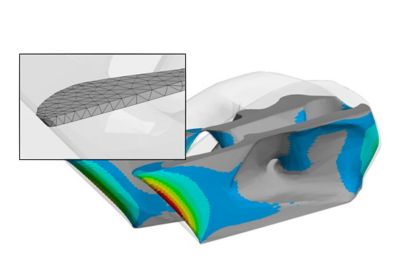

With Ansys Additive Suite, users have access to all Additive tools, including Additive Prep, Additive Science and Workbench Additive.

Critical insights required for a successful Additive Manufacturing workflow

A comprehensive solution for designs, engineers and analysts, Ansys Additive Suite spans the entire workflow – from design for additive manufacturing (DfAM) through validation, print design, process simulation and exploration of materials.

Additive Suite includes Additive Prep and Science tools, in addition to access to Ansys Workbench Additive.

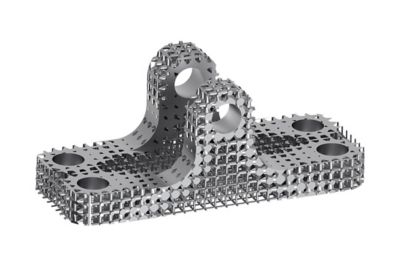

Hyundai engineers used were tasked with re-designing the hood hinge for their vehicles. They chose Ansys as a one stop solution for taking them through Design, Analysis, Product Verification, Process Verification and Production using Additive Manufacturing. This design was also won the grand prize for the 3D Printing DfAM Competition inside Hyundai.

Ansys Additive Suite是一款综合全面的工作流程解决方案,能够为设计人员、工程师和分析师提供所需的关键洞察力。从增材制造(DfAM)设计到验证、打印设计等,该解决方案涵盖整个工作流程,有助于避免制造故障并交付设计准确的部件。

ADDITIVE SUITE CAPABILITIES

Avoid build failure and create parts that accurately conform to design specifications with Ansys Additive Suite. Delivering critical insights for designers, engineers and analysts, this comprehensive solution spans the entire workflow.

With Additive Suite, users gain access to Additive Prep and Science tools, in addition to Ansys Workbench Additive.

Ansys Additive Suite is available as an add-on to the Ansys Mechanical Enterprise license.

Enhance your Additive Manufacturing with:

所有用户(包括残障人士)都可以访问我们的产品,这对Ansys至关重要。因此,我们努力遵循基于美国访问委员会(Section 508)、网页内容无障碍指南(WCAG)和自愿产品可访问性模板(VPAT)的当前格式的可访问性要求。

如果您面临工程方面的挑战,我们的团队将随时为您提供帮助。我们拥有丰富的经验并秉持创新承诺,期待与您联系。让我们携手合作,将您的工程挑战转化为价值增长和成功的机遇。欢迎立即联系我们进行交流。