-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS ADVANTAGE MAGAZINE

DATE: 2020

ANCA Makes Tool Design Less of a Grind

Ansys Dimensions Staff

ANCA CNC Machines is a privately owned, world-leading manufacturer of CNC grinding machines, motion control systems and fabrication solutions, with over 1,000 employees across the globe and annual sales of around $280 million AUD. ANCA CNC grinders are used for manufacturing precision cutting tools and components for the automotive, aerospace, electronics, smartphone and medical industries. Dimensions talked with Pat Boland in Melbourne, Australia to find out what challenges the CNC machining industry is facing today and how ANCA CNC Machines is solving them.

Pat Boland was a 25-year-old electrical engineer in 1974 when he co-founded Australian Numerical Controls and Automation (ANCA) with fellow engineer Pat McCluskey in Melbourne, Australia. They had an idea to upgrade existing numerical controlled (NC) tooling machines with hardwired logic by connecting them to a $4,000 AUD “minicomputer” that stood about 5 feet tall. The resulting computerized numerical control (CNC) machine was a flexible, programmable device for grinding and cutting tools and dies used in wood, metal, ceramics, plastics and composites cutting operations.

CNC has increased the precision of machining operations so that parts can be produced with vanishingly small tolerances for a better fit. When the part is a titanium ball-and-socket joint that will be surgically implanted to replace your worn-out hip, a high-precision fit can make all the difference to your future mobility and comfort. Precision machined parts in airplanes experience less wear and tear and will last longer, increasing safety and reducing maintenance requirements. And the repeatable accuracy of CNC machining reduces costs for consumer electronics parts that are produced in great quantities, like smartphone cases.

"Most machines we sell now are autonomous, machine-tending robots."

Dimensions: What is unique about your company that makes you a leader in the field?

Pat Boland: We operate in a narrow niche, and competition is intense. There are two significant aspects that separate us. First, we are known as innovators in the industry. We have developed a lot of products and processes through the years that have changed our industry in significant ways. For instance, we have developed specialized laser gauges inside our CNC machines to very accurately measure key geometrical properties.

Another important attribute is that we are a very vertically integrated company, so we do not rely on outside suppliers for any of our technologies — we can do every step from design to manufacturing in-house. This means that we can adapt our technology to meet requirements faster than would be possible if we were relying on outside people to make changes. For example, we control the machine itself along with the CNC and servo software that operates the machine.

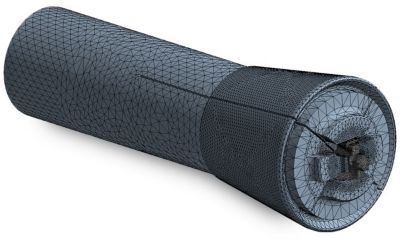

Modal analysis of CNC machine component..

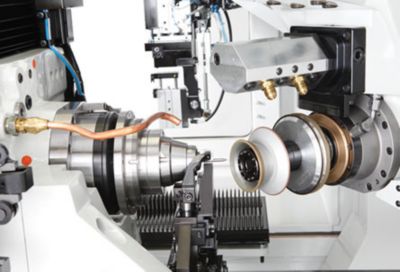

Collet meshing using ANSYS Mechanical.

D: What are some of the major challenges in the CNC machining field today?

PB: Automation is one. Most machines we sell now are autonomous, machine-tending robots. Running in an automated fashion while maintaining high degrees of accuracy is a challenging task. The robot will be loading and unloading components and tools into the machine. You’ve got robots assembling parts into fixtures and fixtures being loaded into machines, which requires vision systems, laser marking and coordinate measuring devices all integrated into single machines.

Also, the accuracy requirement of cutting tools is increasing all the time. In any machining operation, the accuracy of the final machining is limited by the accuracy of the cutting tool. If there’s a geometrical error in your cutting tool, it is going to be transferred to the finished part. So we installed specialized laser measuring equipment inside our CNC machines to measure geometry very accurately. That has enabled unmanned, highly automated manufacturing.

"Greater accuracy leads to a more consistent finished product."

Dimensions: What is driving the requirement for greater accuracy?

PB: Greater accuracy leads to a more consistent finished product. Manufacturers of standard cutting tools are looking for identical performance between a cutting tool made today and one made three years ago. It is no use to customers if one tool has a lifetime of 500 hours and another of the same design lasts only 100 hours. The customer’s system relies on the consistency of the product lifetime, and the lifetime is dictated by the microgeometry of the cutting edge. So that is putting tighter and tighter requirements on the accuracy and surface finish of the products coming out of our machines.

D: Have the skills required of machine tool personnel changed over

the years?

PB: Yes, they need more computer skills than the previous generation of manual tool grinders. I have seen skilled manual operators do some amazing things that were almost impossible to believe, but these skills are no longer required. Still, an operator can make a world of difference by optimizing the process. Today’s operator must be an expert at setting up the machine — qualifying all the grinding wheels in place and getting them into optimal condition for cutting.

D: Are you using simulation to meet some of the engineering challenges of these machines?

PB: Simulation is a key engineering tool for us. Our design engineering team uses Ansys Mechanical for things like friction, deformation and rigidity studies, and for harmonic modal analysis of vibrations. Being able to simulate these physical properties of our CNC machines is much faster and less expensive for us than building physical prototypes and testing them. We can detect any potential problems virtually and have confidence that we have corrected them before we begin building. This helps us deliver our product to a customer sooner and at a more competitive price.

More recently, our manufacturing engineers have learned from the design team and have begun to use Mechanical to simulate fixtures, jigs, lifting apparatus and other practical tools they use in the manufacturing process. Besides using Ansys solutions, we have also developed our own software for downstream simulation of actual machine operation.

D: What does the future of the CNC machining business look like?

PB: We are seeing good trends in most markets, with the exception of China and Korea. A lot of our machines are used in the smartphone supply chain in those countries. But there’s been an incredible wave of investment there in the last five years, and they are now overstocked on CNC machines. No new orders coming from that region will have an impact on part of our business. But the advantage we have is that cutting tools are used throughout the world. Besides that, they are used in a diverse range of industries from woodworking, furniture making, metal cutting, mining — all the way through to brain surgery, the medical side of precision cutting tool applications. Increased demand for CNC machines in these other sectors should make up for the cutback in the smartphone sector.

Dimensions: It sounds like as long as people are manufacturing things they will be needing CNC machines like yours.

PB: Yes. As long as people are sitting in chairs, using knives and forks, and getting around in some sort of motor car — electrical, autonomous or whatever — there will be a need for cutting tools.

The key is continuing to deliver reliable products. When we started this business in the 1970s, people were more tolerant of development cycles. Today there’s an expectation that things will be designed quickly, and that they will work out of the box, from serial number one through to the last serial number. Quality of design is a critical driver, so we need simulation for design verification. Simulation plays an absolutely critical part — being able to evaluate performance before you actually make a physical prototype is crucial.

ANCA CNC Machines at a Glance

ANCA CNC Machines is supported by Ansys Elite Channel Partner LEAP Australia Pty Ltd.

| 2017 revenue: | $280 million AUD |

| Number of employees: | 1,000 |

| Headquarters: | Melbourne Australia |