-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

April 5, 2022

X1 Wind Floats Unique Energy Harvesting Technology Thanks to Ansys Startup Program

Our reliance on fossil fuels undoubtedly poses one of the biggest threats to the environment. The urgency to find sustainable energy alternatives in solar, wind, and water is greater than ever. Of these, wind power is an extremely cost-effective, clean, sustainable energy source for consumers. However, one challenge of wind harvesting involves allocating acreage to and connecting the energy generated by remote, land-based wind farms with urban power grids.

By taking wind energy technology offshore, the prospects for wind power expansion increase dramatically. Our planet’s vast bodies of saltwater offer limitless possibilities for wind harvesting, yet most remain untapped or underutilized due to wind turbine installation costs, and maintenance challenges. With the support of the Ansys Startup Program, startup X1 Wind, located in Barcelona, Spain, gained valuable access to Ansys simulation software and developed a disruptive floating wind technology that can mitigate these challenges and radically transform energy production.

Approximately 70% of the Earth’s surface is covered by oceans, representing a 140-million-square-mile area that holds enormous potential for floating wind turbine applications. According to the International Energy Agency (IEA)—an organization dedicated to helping countries achieve sustainable energy objectives through authoritative analysis, data, policy recommendations and real-world solutions— the technical potential for offshore wind worldwide is 120,000 Gigawatts (GW), enough to meet the projected global demand for electricity 11 times over in 2040. So just how does an offshore floating wind turbine fit into this scenario?

The X30 Floater: X1 Wind’s Unique Floating Wind Turbine Design

Once moored to the ocean floor, wind turbine networks can be established, connected by high-voltage direct current cables to supply power to coastal mega grids. Of course, there are various logistical challenges that come into play working offshore in deep waters. Initial wind turbine installation is costly and complex, requiring expensive, specialized vessels and the expertise needed to secure a foundation underwater in varying seafloor conditions. A wind turbine also has many moving parts, including the turbine blades, gearbox, generator and transmission cables — some being challenged by erosion, the weather, and occasional damage from passing ships while operating continuously. Depending on just how far offshore the turbines are located, any significant delays due to unforeseen weather events or other logistical challenges can be costly.

Pushing Boundaries in Floating Offshore Wind Design

Carlos Casanovas, co-founder and chief technology officer of X1 Wind, developed the X30 floater to address these challenges and deliver clean, affordable energy while reducing emissions across the globe. The young entrepreneur has an extensive background in wind turbine design, including time spent working at Alstom Wind, now part of the GE Group. The X30 floater is the realization of Casanovas’ vision of how the wind energy could be harnessed in deep waters by taking advantage of the complex offshore environment. Casanovas would eventually leave the company for the Massachusetts Institute of Technology (MIT), where he worked on his floating design concept while pursuing his master’s degree to further push the boundaries of his ideas. In 2017 he formed X1 Wind to bring these ideas to life with help from several benefactors, including the Ansys Startup Program. He was first introduced to Ansys simulation software on the job at Alstom Wind, so for him, it was a natural choice.

“Going into this project, I was already familiar with the software and its capabilities,” says Casanovas. “When we started out, we contacted Ansys to purchase our first license and were told we were eligible for their startup program. To get those full-license products for very reasonable cost has been very helpful for our development and testing activities. Plus, many of our senior team members already had experience with Ansys software, so for us it was a no-brainer.”

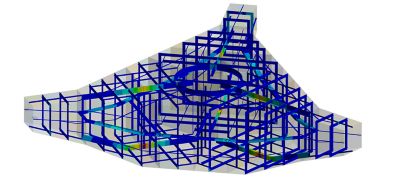

Interior view of the Tension Leg Platform (TLP) floater, to which the mooring lines are connected

Conventional offshore wind turbine towers are supported by large steel structures anchored to the ocean floor. The blades are affixed to the top of the stationary tower. In deeper waters, installing and maintaining these foundations becomes increasingly impractical. The X30 floater is a self-orienting downwind wind turbine design characterized by a wind turbine in a downwind configuration. Removal of the traditional stationary tower resulted in a unique tripod-like floating structure that is anchored to the ocean floor by a single-point mooring system. The lighter pyramidal design has a lower center of gravity that can engage in more efficient load transmission through tension and compression with low bending moments. The downwind design does not require pre-bent blades like conventional upwind offshore turbines, which allow turbine blades to be lighter, longer, and cheaper.

Casanovas’ patented PivotBuoy single-point mooring integrates into the downwind configuration. This unique design enables the platform to passively weathervane or pivot in the direction of the wind, using mooring lines instead of fixed piles to anchor the system. The single mooring system can be pre-installed, while the floating structure can be quickly assembled onshore, then towed using local vessels for quick connection to the single point mooring system. The result is a more sustainable, reliable energy-harvesting solution that enables modular, scalable construction for quick, cost-effective installation using local infrastructure.

“We need to try to make our floating wind structure reliable and strong enough to remain competitive, because with renewable energy, it's all about the final cost of energy,” says Casanovas. “If your floating design is very heavy and expensive to build, you will not be very competitive, so structural integrity is a really fine line for us. It’s important to have the right simulation tools so that you can do all the optimization that you need to do, and Ansys checks all the boxes.”

Simulating More Sustainable Offshore Solutions

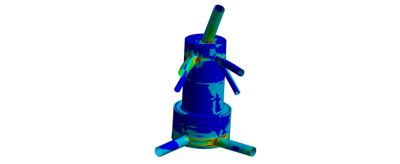

Ansys simulation software was instrumental in helping X1 Wind meet specific structural requirements for the X30 floating design. It was part of the team’s greater workflow, which moved seamlessly at the modeling stage from SolidWorks software to Ansys Mechanical finite element analysis software for structural engineering. Ansys SpaceClaim 3D computer-assisted design modeling software was used as an intermediate step to improve the geometry of the model to optimize it for further analysis. The team then used Mechanical for model analysis of both extreme loads and fatigue to verify that all structural stresses were under acceptable limits. The software was also used to verify the plastic deformation of various components.

The future for X1 Wind is looking very bright. Commissioning their first prototype, X1 Wind plans to install the X30 demo floater somewhere in the waters off the Canary Islands in the upcoming months. Deployment of the PivotBuoy project was funded by the European Commission’s Horizon 2020 program, part of a dedicated effort to invest in new solutions to address societal challenges and drive innovation-led sustainable growth. However, Casanovas was quick to point out that the support of the Ansys Startup Program was extremely valuable in the realization of the X30 floater.

Exterior view of the starboard main column with the pontoon termination in an extreme load case

“Considering the requirements surrounding wind energy and the complexities of the architecture as a whole, product development would have been much more difficult without the support of the Ansys Startup Program,” says Casanovas. “Without the access to Ansys software needed to help build advanced finite element models, it would just be too much of a challenge for such a small team.”

Get more information on the Ansys Startup Program.