-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

October 12, 2023

Where the Real Work in Space Gets Done

Rockets get all the glory. Sure, they’re big and flashy. They produce an impressive amount of noise and billowy clouds when they lift off. But, once they’re up in space, once they’ve pushed their payload beyond the tug of gravity, that’s when the real pros take over.

We’re talking about release actuators. Yep, those little mechanical devices whose pins snap forward to launch those modern CubeSats from the payload bay of the rocket.

You might be raising a skeptical eyebrow right now but think about it: At just the right time, an actuator clicks and a CubeSat pops out of the rocket in just the place it’s supposed to be. Another actuator clicks on the CubeSat itself, and the solar array that will power that tiny satellite unfurls and blossoms like a flower, becoming a light-catching surface many times larger than it had been when folded up in the rocket’s payload bay. Without release actuators, those satellites would just sit inside the rocket, no good to anyone.

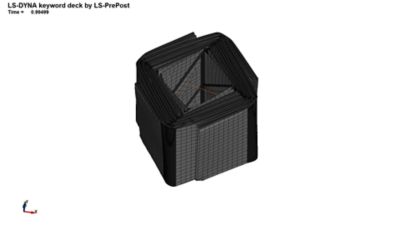

A meshed model of a DCUBED CubeSat before deployment.

So, here’s the interesting question: Given that the proper performance of a release actuator is critical to the success of an entire satellite launch plan, how can an engineering team be confident that the actuators are going to perform properly when the time comes to pop? One can build a prototype of an unfurling solar or antenna array, but how does one validate that the design will work in an environment where there is no gravity and where the temperature may vary between -100°C and +120°C?

To solve these kinds of problems, the engineers at the German space firm DCUBED rely on Ansys software to simulate the performance of the company’s release actuators and other deployable satellite components in space — and gain the critical insights needed to optimize and ensure product performance without ever leaving the ground. As a member of the Ansys Startup Program, the company gains access to Ansys multiphysics simulation software and high-performance computing (HPC) resources at an affordable price.

The New Space Initiative

DCUBED is part of the New Space Initiative of the Federal Association of Germany Industry (the Bundesverband der Deutschen Industrie eV or BDI), which aims to commercialize space travel and connect it with the traditional economy. Early efforts involve the deployment of large constellations of very small satellites or “CubeSats” that work together as a network to capture and transmit information. These constellations of satellites can bring internet services to remote regions; provide real-time data to autonomous vehicles; transmit weather and crop information to distant farming communities; and perform many other tasks for a wide range of industries.

But getting those objects into space is a challenge.

“There’s not much room in a rocket,” says Thomas Sinn, Ph.D., Founder and CEO of DCUBED, “so companies sending structures into space need a way to pack them in a very compact manner and then expand them into larger structures in space.”

That’s where the release actuators and deployable structures from DCUBED come into play.

“For example, in creating solar arrays,” explains Thomas Lund, DCUBED’s Head of Analysis, “DCUBED takes take a modular approach. A customer can tell us the power, the current, the voltage, and the area to which the array must expand. It can tell us the keep-out zones, and we can go on to design the array using our off-the-shelf actuators, analyze it to ensure that it’s going to unfold and perform as expected, and deliver it rapidly to meet the customer’s needs.”

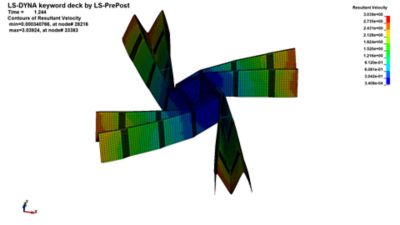

Simulation of the contours of resultant velocity in an unfurling array.

DCUBED uses Ansys Mechanical to propose a design that meets a customer’s specifications. Then, to ensure that the array will unfold as intended and deliver the radiation-absorbing qualities expected, they rely on Ansys LS-DYNA, a simulation tool designed to simulate the response of materials to short periods of severe loading.

“LS-DYNA is the only solver that could perform highly nonlinear simulations involving a lot of very large displacements, which is what we need when looking at inflatable space structures,” says Sinn. “As we began working on deployables after developing the release actuators, it was clear that LS-DYNA would be the ideal tool for working with the kinds of deployables we were developing.”

Addressing the Multiphysics of Space

Designing a deployable space product for a client involves a bit of creative iteration at DCUBED. The team follows a conceive/design/initiate/operate process in which engineers conceive of a solution to meet the client’s needs, propose a design using Mechanical, and then test that design against the conceptual criteria.

“Most of the time, you’re going to encounter failure,” notes Lund, “so you cycle back to the concept and come up with a new design.” Eventually, the design tests fulfill the conceptual criteria and the engineers take the design to initiation — and still more tests — to determine whether the design is going to perform as intended.

“We always do a lot of rapid prototyping of our designs using 3D printers,” says Lund, “but no one has the time or money to produce every design concept as a physical prototype to be tested. Even if you could, the real test is whether the design will perform as expected in space. It’s very expensive to put a prototype in space, and it’s just not possible to get the boundary conditions right when you’re working with physical prototypes on Earth, so you have to use analysis.”

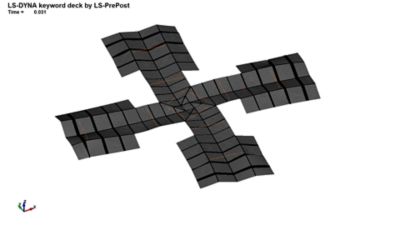

A meshed model of a DCUBED array when almost fully unfurled.

The DCUBED team use LS-DYNA to simulate a design’s performance in the conditions that a will encounter in space. LS-DYNA provides the flexibility to conduct both steady-state and transient simulations. Steady-state simulation helps the team understand how a design is going to behave at a specific point in time, while transient simulations yield insights into the behavior of the deployable over time in the different conditions that the rocket and its payload will encounter.

The transient simulations that LS-DYNA facilitates are particularly important because they enable Dr. Sinn’s team to consider where a rocket might be at any time relative to sunlight vectors and the Earth’s shadow. If a release actuator pushes a deployable out of the payload bay while the rocket is in the Earth’s shadow, the temperature of space may be -100°C. But moments later, when the deployable is struck directly by the sun’s rays, the temperature may climb to +120°C. When a structure encounters these widely varying temperatures, it’s going to expand or contract depending on the materials involved. That will have implications for structural soundness as well as mechanical performance.

Release actuators come in a variety of sizes and can push an item out into space or facilitate the unfolding of a complex deployable.

DCUBED creates deployable solar array and antenna structures that can expand to full size in space.

Subtract gravity from the equation and the complexity of the environment grows even greater. The European Cooperation for Space Standardization (ECSS) and the European Space Agency (ESA) have defined standards for environmental conditions in space, and those can be parameterized in LS-DYNA — as can details about the materials used in an actuator or deployable structure.

“Space really poses a multiphysics problem,” says Lund, “and you need to work with multiple simulations simultaneously to gain the insights you’re looking for. When you combine solvers the way Ansys does in LS-DYNA, where you have both thermal and structural in the same solver, you gain a cohesive understanding of how a deployable is going to perform in that complex environment. That is a huge advantage for us.”

“We got into this because we love the space industry and the benefits that space has given to the world,” says Sinn. “We want to enable more of that. For us, it’s all about helping our customers accomplish their goals. Simulation makes it possible for us to test our actuators and deployables in a wide range of conditions so that we can deliver products that will work reliably within as wide a window of conditions as possible. That gives our customers the flexibility to deploy their products when and how they want in order to meet their goals.”