-

United States -

United Kingdom -

India -

France -

Deutschland -

Italia -

日本 -

대한민국 -

中国 -

台灣

-

-

产品组合

查看所有产品Ansys致力于通过向学生提供免费的仿真工程软件来助力他们获得成功。

-

ANSYS BLOG

May 13, 2020

Can Ultraviolet (UV) Light Disinfection Fix PPE Shortages?

One of the biggest concerns the public has during the COVID-19 crisis is the shortage of personal protective equipment (PPE) that prevents the spread of illness.

PPE can help doctors and nurses stay safe as they treat patients and assist the general public in flattening the curve.

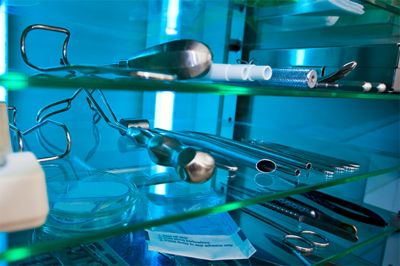

Sterilized medical equipment

The PPE supply chain is stressed in times of crisis, because the equipment can only be used once — before being discarded. Since PPE is in high demand, engineers and medical practitioners are looking for ways to sterilize the equipment for reuse.

One potential solution is to use the same ultraviolet light disinfection technology that sterilizes myriad medical equipment. With the use of simulation, engineers can design new equipment, or optimize the efficiency of current equipment, to reduce the one-and-doneness of PPE.

How Ultraviolet Light Disinfection Works

According to the Centers for Disease Control and Prevention (CDC), ultraviolet germicidal irradiation is a disinfection method that uses short-wavelength light to eliminate, or inactivate, microorganisms.

The high energy light kills bacteria and viruses by reacting with their nucleic acid. Unfortunately, this technology isn’t very effective against bacterial spores.

A test performed under ultraviolet light disinfection

Many industries use ultraviolet light disinfection to sterilize water, air, implants, contact lenses and surfaces. These processes use a strong light source, at wavelengths between 240 to 280 nanometers, in an air or water circulation system. The system runs until the environment is inhospitable to the microorganisms.

The CDC states that the effectiveness of the germicidal light is dependent on many variables, including:

- Organic matter/microorganism

- Wavelength and intensity of the light

- Suspension material

- Temperature

- Distance between the light source and microorganism

- Cleanliness of the system

Remember that this technique is currently limited to the sterilization of surfaces and objects. For instance, the CDC notes that a double-blind study of almost 15,000 patients showed that ultraviolet light was ineffective at reducing infection rates of postoperative wounds. Additionally, the CDC and World Health Organization (WHO) caution that treating a body with ultraviolet light could cause injury.

Simulation Can Help Engineers Design Ultraviolet Light Disinfection Systems

The latest developments in ultraviolet germicidal irradiation technology has seen the emergence of LEDs that can be used as alternatives to traditional mercury lamps. These semiconductors emit light between 255 and 280 nanometers and reduce the size of sterilization systems. This enables engineers to better integrate them into medical devices.

Ansys Speos radiometric analysis shows that the minimum irradiance for the disinfection process takes four seconds.

Ultraviolet LEDs also have a better tolerance for short-term operation. As a result, they can achieve a longer service life than mercury lamps, when used intermittently. This makes LEDs a perfect candidate for disinfecting a large number of PPE masks in a short amount of time.

A simulation that shows ultraviolet light disinfecting PPE masks..

However, engineers need to prove that this technology can be adapted to disinfect a surface as porous as a PPE mask. To perform this task they can use simulation tools, like Ansys Speos, to design a system that maximizes disinfection by altering:

- Power of the radiant flux

- Number of LEDs

- Position of LEDs

- Materials used to interact with the light

The simulation results can also determine:

- Exposure time required to disinfect

- Radiometric power on the complete surface

- Efficiency of a device

- Optimal device configurations

As these simulations can help engineers iterate designs faster than using physical prototypes, they will be able to quickly design, optimize and validate an ultraviolet light disinfection system that can sterilize PPE and other medical equipment, which could help battle COVID-19 and future infectious diseases.

To see other ways that simulation can help battle COVID-19, read: Facing COVID-19 Challenges with Our Customers and Partners.